tl;dr: The Toyota Production System (TPS) — often called Lean — is not primarily about tools. It is a management philosophy centered on people development, leadership behavior, and continuous improvement. When organizations focus only on Lean tools without the underlying philosophy, results are often short-lived.

What Is the Toyota Production System (TPS)?

The Toyota Production System (TPS) is often described as a set of Lean tools like 5S, kanban, and andon cords.

That description is incomplete.

At its core, the Toyota Production System is a management philosophy — focused on developing people, solving problems at the gemba, and practicing continuous improvement.

Organizations that copy the tools without adopting the philosophy rarely sustain results.

Here's why.

Lean Is a Philosophy, Not a Set of Tools

I made a few tweaks to the content of the third edition of my book Lean Hospitals based on some input from Jamie Bonini, vice president of the TSSC group within Toyota. They are the ones who did the great work with UCLA Harbor Medical Center and others, as highlighted in “The Toyota Effect” videos and earlier work with the NYC Food Bank.

Jamie talked with me and contributed several thoughts and ideas about the Toyota Production System and what we might elsewhere describe as “Lean Culture.”

That philosophy includes Lean's core principle of Respect for People, which is about developing capability and designing systems that allow people to think and improve.

What Are the Two Pillars of the Toyota Production System?

The two traditional pillars of TPS are:

- Just-in-Time (JIT) – Delivering what the customer needs, when it's needed, in the right amount

- Jidoka (Built-In Quality) – Designing processes that detect problems and stop to fix them

These pillars define the structure of the Toyota Production System — but they rest on something deeper: philosophy and people development.

Without that foundation, the pillars collapse–or never stand to begin with.

The Toyota Production System as an Integrated System

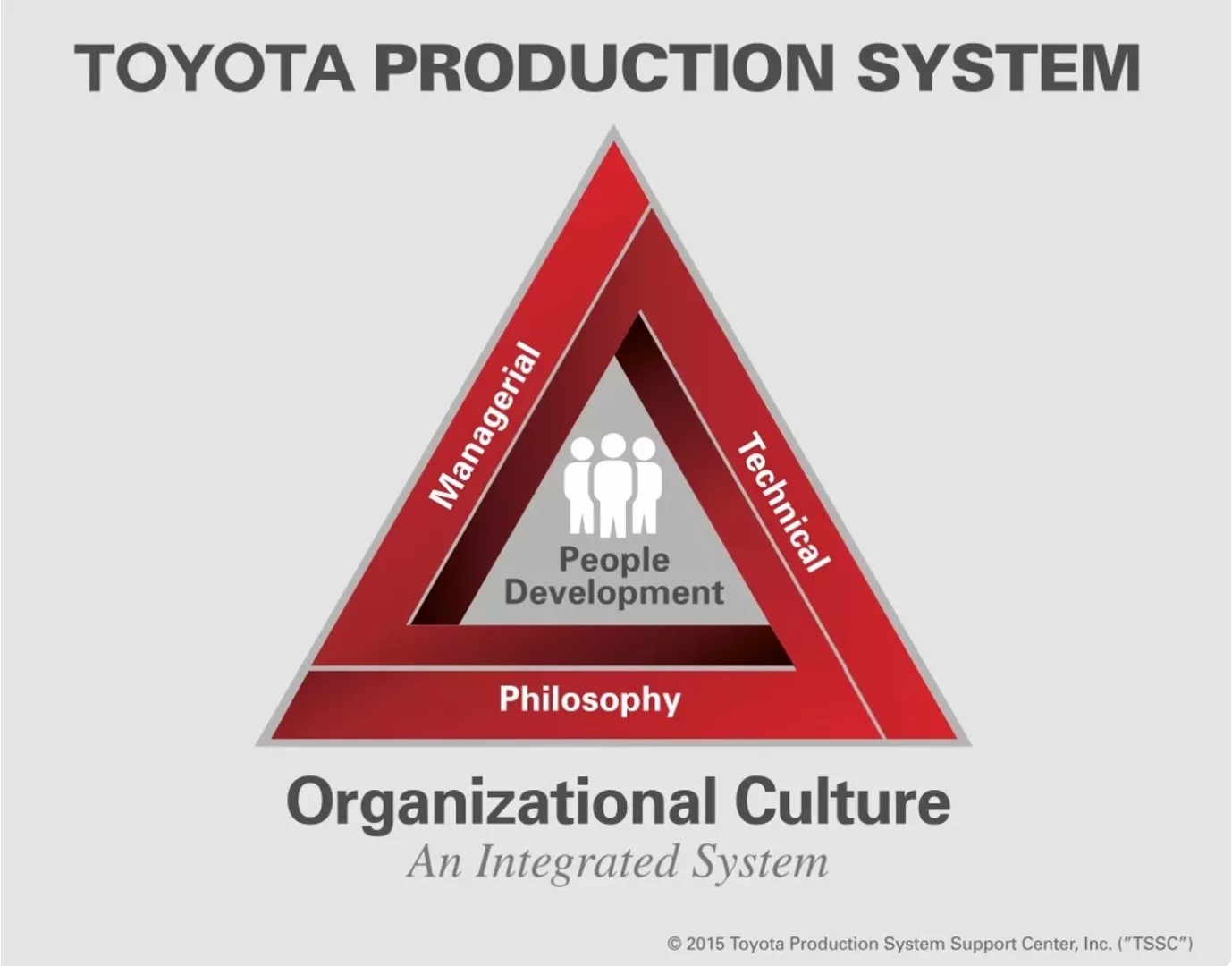

There's a triangle diagram on the TSSC webpage that describes an “integrated system” that consists of:

- technical methods

- managerial methods

- philosophy

All of this is “focused on people development,” Jamie told me for the book.

The model starts with people and human development in the middle, as “people are the most valuable resource,” says Bonini.

This is a triangle that I first heard mentioned almost exactly 10 years ago by Gary Convis, a former Toyota executive, and I had included my own version of the diagram in earlier editions of the book. I had never seen the official Toyota version of it… I had just created my own based on the description.

Listen to Mark read this post (subscribe to the podcast):

Jamie told me, in one discussion, that the philosophy is the most important thing. That doesn't mean it's the only thing. From what I've seen, Lean tools are an offshoot of the philosophy. A certain philosophy leads to the development of tools or methods like “andon cords” or 5S. The tool without the underlying philosophy is definitely missing something.

The Core Elements of Toyota's Lean Philosophy

What is that philosophy? Jamie says it has four parts:

- Customer first; provide customers with what they want, when they want it, and in the amount they want it

- People are the most valuable resource; Deeply respect, engage, and develop people

- Continuous improvement (kaizen); Engage everyone each and every day

- Shop floor (gemba) focus: Go to where the work is done to find and solve problems

If any of that philosophy is missing, I'd say that's where so-called “Lean” efforts start seeming more like L.A.M.E. than Lean.

Why Lean Fails Without the Underlying Philosophy

When I've complained about cost-cutters who masquerade as Lean thinkers, Jamie told me:

“There are cases where people are pushing Lean, just focusing on tools and the results those tools can get. It can be powerful… they can get great results, but it's a double edged sword. But they're not using them with the right managerial approach and philosophy.

They're getting exposed to just one third of an integrated system.”

The philosophy, the mindsets, and the ways of thinking — those are the most important elements of Lean or the Toyota Production System. This is why TPS is often described as a Lean management system, not just a production system.

A Reflection for Leaders Practicing Lean

Lean doesn't start with tools. It starts with philosophy.

Organizations can copy the visible parts of the Toyota Production System — the tools, diagrams, and terminology — but without the underlying philosophy, those efforts rarely last. Tools without mindset may deliver short-term gains, but they don't create sustained improvement or a healthy culture.

Toyota's focus on customers, people development, continuous improvement, and going to the gemba reflects a way of thinking that shapes behavior long before it shows up in metrics.

So the real question for leaders isn't “Which Lean tools should we use?”

It's “What philosophy is guiding our leadership decisions and daily behaviors?”

Adopting a new philosophy is harder than copying tools — but without it, Lean becomes activity instead of a system for learning and improvement.

How does your organization align with those four points of Toyota's philosophy? Do you have your own philosophy that is still compatible with Lean methods? Can an existing organization hope to actually adopt a new philosophy? That's far more difficult than copying a few Lean tools.

Frequently Asked Questions About the Toyota Production System

What is the Toyota Production System?

The Toyota Production System (TPS) is a management system developed by Toyota that integrates Just-in-Time production, built-in quality (jidoka), respect for people, and continuous improvement to create long-term operational excellence.

Is the Toyota Production System the same as Lean?

Lean is derived from TPS. However, TPS places stronger emphasis on philosophy and people development, not just tools.

Why do TPS implementations fail?

Most fail because organizations copy the tools without adopting the underlying philosophy and leadership behaviors.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.

Thanks for sharing, Mark. I love the triangle and the 4 steps. I’m often asked the question, “How do I build a Lean culture?”, and it’s a tough one to answer. This information can provide a guideline from which to assess progress toward the goal.

By the way, good luck with the new edition of the book.

Thanks, Dean. I agree this is a helpful framework. I wouldn’t call it “4 steps” as in being sequential, but 4 points that are interconnected and required.

Thanks also for your help in introducing me to the publisher originally! :-)

No problem. The book has been a great success – well done. I recommend it whenever I speak to a healthcare audience.

As Dr. Deming said…. we have to “adopt the new philosophy.”

Easier said than done.

See Michel Baudin’s post on the “new philosophy.”

Lean and Deming was always easier for me to embrace because this is what I learned at the START of my career.

Trying to embrace this after 20 or 30 years as a leader… I can’t imagine how difficult this is.

Hi Mark,

Without question, the TPS – both past and present – represents a very challenging entity to define and characterize; especially in ways that accurately and comprehensively convey the essence of what it really is. In this regard, my reading of this article and my listening to Jamie Bonini (VP of TSSC Group) leave me with little more than an obfuscated impression of what they are attempting to convey.

Note: I’ll be the first to admit that the English language presents major challenges to any user in terms of capturing and conveying precise and readily comprehensible interpretations/translations of ideas/concepts/notions; particularly those that evolved in unique ways and in unique environments.

By way of providing examples of what I’m referring to, the following instances represent major “disconnects” that are being “built-into” the definition/interpretation of the TPS/Toyota Way:

1) In the video that appears on the TSSC website, JB states that “the Toyota Production SYSTEM is a “CULTURE.” Well, if that’s really the case, then why not simply call it the Toyota Production CULTURE or just the Toyota CULTURE?

2) Then, he and the triangle diagram go on to portray the TPS as an organizational “CULTURE;” one that consists of three key elements: “PHILOSPHY” (i.e. improvement-oriented, hands-on learning-by-doing), “TECHNICAL TOOLS” being portrayed as architectural “PILLARS” supporting the notions of Quality, Cost and Lead-time (i.e., JIT-related and Jidoka/Autonomation-related, both of which are resting on a base of “STABILITY”).

3) As JB goes on to describe/explain the objective underlying the use of the JIT-related TOOLS as working for [toward] a state [of being][such that] when a customer makes an order, we can deliver their product one-by-one, immediately… the essence of a high level of “FLOW.” … “That tells you that this BUILT-IN QUALITY ASPECT (????)is WORKING AT A HIGH LEVEL (?????).”

4) And then JB goes on to explain the third “piece” of this “SYSTEM” (I thought we were referring to TPS as a “CULTURE”) as a MANAGERIAL “ROLE” (i.e., developing people to surface problems and solve problems to make improvements). He concludes (and rightly so) that it’s only when the three are working together that one can have very “powerful SYSTEM” that can deliver “sustained results”… WHAT RESULTS?

Note: I don’t know about you, but to me this description of the TPS/Toyota Way – as presented by JB – turned into a major hairball of interwoven, entangled ideas/notions/concepts. It’s being presented in a manner that I like to refer to as the RAGU SPAGHETTI SAUCE approach; that is, “IT’S [ALL} IN THERE.” In fact, as a result, what’s being totally lost in the explanation is the fact that the TPS/Toyota Way is actually a SYSTEM that represents a highly-structured/integrated/systematic and systemic/holistic approach to pursuing and sustaining superior levels of operational excellence; one that is continually evolving/emerging/adapting in response to the changing conditions in the overall business milieu in which the SYSTEM exists. It makes no mention whatsoever of the need to for all members of the enterprise to engage in SYSTEMS-THINKING as a foundation for pursuing improvement. Accordingly, it’s no wonder that there is so much confusion around the notion of “lean” and how it relates back to the TPS/Toyota Way. Depending on who attempts to do the untangling and explaining, there is a greatly increased likelihood that what results will be a plethora of conceptual explanations, all of which are different and subject to being made actionable via different approaches. YIKES!!!!

I guess it goes to show that Toyota still has room for improvement in how they explain this.

Part of the challenge is that we’re asking them to be a fish who describes the water that surrounds them.

It’s like a person being asked to explain, “What does air feel like?” or “Explain to me how to breathe?”

One thing Bonini is trying to get across is that TPS/Lean is an “integrated system.”

Fujio Cho has tried to explain the same (as recounted here:

Too many organizations try to pick and choose the parts of Lean that sound good to them, ignoring other parts of the integrated system…

Hi Mark,

I have a question. How difficult it is to implement a new philosophy or new Lean Technique in the Organizations?

It’s much easier to adopt a few Lean tools than it is to adopt a new philosophy. Culture change is hard.

IS adoption of Lean tools a time taking process?

Thanks

[…] quality management practices run deep at many Japanese hospitals, it does not appear that a full Lean management system is yet being practiced in hospitals in […]

[…] We covered basic Lean methods and principles, emphasizing that Lean is not just tools, it’s a philosophy and a management system. […]

[…] (the Japanese word jidoka), through detecting and preventing errors, is one of the pillars of the Toyota Production System.[xiv] The history of jidoka dates to the time before the company even built cars. Sakichi Toyoda […]