t;dr: A visit to Toyota's North American headquarters offered more than a virtual plant tour. It revealed how Toyota blends the Toyota Production System, Lean leadership, and learning from crisis to build trust, improve communication, and continuously improve–inside and outside the factory.

Last month, I had an opportunity to visit the Toyota North American Headquarters that's now near me in Plano, Texas. Thanks to the MIT Club of Dallas / Fort Worth and the Public Relations Society of America chapter for creating this opportunity.

Before touring the “Experience Center” with the virtual tour, there was a panel of Toyota leaders discussing communications and public relations.

The Experience Center, as cool as it is, is not open to the public (at least at this point). A Toyota leader talked about how they want Toyota team members to invite people as their guests and to feel like “hosts.”

They said:

“The customer is center of everything we do.”

The phrasing echoes the core purpose behind the Toyota Production System–delivering value to the customer through systems that support people doing the work. Tools like Just-In-Time and Jidoka aren't just about process–they're how Toyota translates customer focus into operational practice, every day.

To that point, the Experience Center has a live, working “customer service center” that takes phone calls as one way of better understanding the “voice of the customer.”

One of the panel speakers, Brian, had a background in engineering and production. He took a role in communications right before the allegations of “unintended acceleration.”

That's something I talked to Jeff Liker about in a podcast about his book Toyota Under Fire (and Brian was one of the people who talked to Jeff for the book):

One lesson shared by Brian:

“Don't assume your reputation will carry you through a crisis.”

He also talked about working with reporters and looking internally for improvement instead of blaming reporters, when he asked:

“Where did we go wrong that we're not being believed?”

The whole episode, according to another Toyota leader, Nan Banks:

“It's made us better communicators and a better company overall.”

Toyota has learned that the lines between “internal communications” within a company and “external communications” have blurred.

The communications team was “challenged to come up with innovative ideas,” so they converted a storage closet into a podcast studio and released a podcast called “Toyota Untold.”

They also have a series of videos called “American Journey.”

I appreciated hearing the perspectives of the Toyota communications team, but the highlight of the evening for me was a chance to walk through the Experience Center. There were many cars from different eras on display, including this old Toyota Corona:

A Virtual Tour, a Real Lesson in Flow

For everything in the Experience Center, I was blown away by the “virtual reality tour” of the Toyota plant in Cambridge, Ontario.

Here are some photos of me wearing the VR gear (which runs off of a smartphone) — click any photo for a larger view:

It was an incredibly immersive experience. I've been on Toyota plant tours in San Antonio and Japan and it very much reminded me of that experience.

Once I got oriented in the VR goggles, I realized I was on a tram that was driving through the factory (this was very reminiscent of the tour in San Antonio).

The VR was amazing, as I could look up, down, and around in 360 degrees (and those rails were very helpful to hold onto).

But, the VR tour was better than a physical plant tour in that it took you through the stamping and paint shops (areas they avoid in a physical tour due to safety, noise, and possible human contamination of the paint).

There were times when the VR tour perspective put me literally INSIDE of a car that was going down an assembly line. I could see team members installing parts inside the car I was “in.” They took the car through final inspection and out to a rail car for shipping (again, with me being virtually inside the car for that).

I'm going back to Japan again in December and that trip will include a Toyota tour. It's amazing to see the possibilities that arise from a virtual tour of a Toyota plant.

TPS in Practice: From Jidoka to Kanban

The Experience Center, of course, had displays about the Toyota Production System. There was a display that explained some of the core TPS terminology:

What stood out to me is how TPS terms are not abstract ideas–they're practical elements of a deeply aligned management system. Each concept is interdependent: for example, Andon connects to Jidoka by enabling people to stop the line when a problem is detected, signaling a need for support rather than creating fear. It's a technical system designed to build trust and drive learning in real time.

The Dual Pillars: Continuous Improvement and Respect for People

Before diving into details, there was a display about the dual pillars of The Toyota Way management system (click for a larger view):

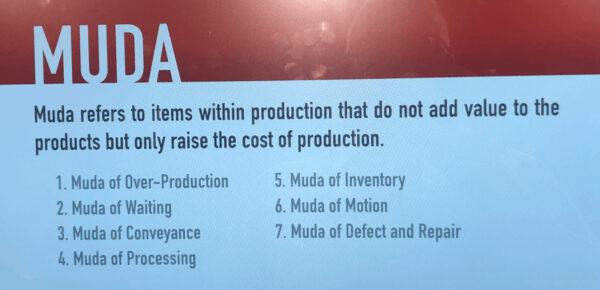

Beyond Just-In-Time and Jidoka, the Experience Center offered clear definitions of other TPS elements–each reinforcing the broader system of flow, quality, and respect. When viewed together, they represent more than tools; they are habits of daily practice that create a culture of continuous improvement.

Read more about those three pieces the the philosophy in this blog post:

Kaizen and Standardized Work: Partners in Improvement

Kaizen is often misunderstood as occasional brainstorming events. At Toyota, it's a daily practice of improvement by everyone, everywhere–no matter the size of the change. It reflects the belief that those closest to the work are best positioned to improve it.

Read about a Toyota tour guide's Kaizen in Japan, as an example of that:

Toyota says that standardized work is necessary for Kaizen.

Toyota says that standardized work is necessary for Kaizen–and that's not about rigid conformity or stifling creativity. It's about creating a shared, stable foundation that allows everyone to improve together. Without a clear current standard, we can't tell if a change is actually an improvement. And without engaging people in defining and refining that standard, we risk building systems people don't believe in or won't follow. At Toyota, standardized work evolves through collaboration and experimentation–it's a living baseline for learning.

In Healthcare Kaizen, Joe Swartz and I wrote about how standardized work allows hospitals to reduce variation in critical processes while still encouraging innovation. Whether in a factory or an ICU, clarity about the current best practice is what makes improvement possible.

Problem Solving at the Root: The 5 Whys and Beyond

One way Toyota solves problems is through “the five whys”:

This practice–asking why repeatedly–reflects a deeper cultural commitment to learning, not blaming. It's easy to stop at a surface-level answer, or worse, to point fingers at individuals. But effective use of the 5 Whys digs into systemic causes and highlights what we can improve in the process, not just the people. The goal is prevention and learning, not punishment.

Beyond Waste Elimination: Understanding Flow and Human Potential

Toyota talks about the “seven types of waste” — not including what many call the “eighth waste” of human potential. Maybe it's just assumed, at Toyota, that people are engaged and, therefore, that waste doesn't exist?

And a few more:

Takt time isn't just a metric–it's a guiding rhythm that aligns production pace with actual customer demand. It helps identify bottlenecks and ensures flow isn't driven by internal convenience, but by external need.

Lean isn't “all about efficiency,” as some Lean Six Sigma people teach. At its core, TPS is about delivering flow and quality in service of the customer, while respecting the people who do the work. Tools like takt time and kanban help balance demand and capacity, but the ultimate goal is a humane and effective system–one where people can do their best work without firefighting, overburden, or rework.

Too often, Just-in-Time is misunderstood as simply reducing inventory or increasing speed. But at Toyota, JIT is about creating the right conditions for flow–minimizing delays, reducing rework, and aligning production rhythm with customer demand through tools like takt time and kanban. It's not efficiency at the expense of people or quality; it's about building a system that delivers value reliably and responsively.

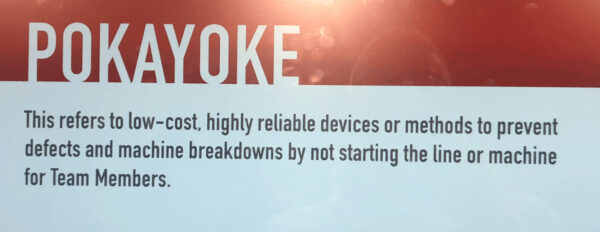

Poka-Yoke: Designing Systems That Help People Succeed

Mistake-proofing, or Poka-Yoke, is one of my favorite TPS concepts because it reflects both engineering ingenuity and human-centered design. As I wrote in The Mistakes That Make Us, the best systems don't expect perfection from people–they support it through thoughtful design. Whether it's preventing a wrong part from being installed in a car or making it harder to skip a critical step in a surgical checklist, Poka-Yoke is about anticipating how mistakes happen and building in mechanisms that either make them impossible or at least easier to catch and correct early.

In healthcare, I've seen Poka-Yoke principles applied through color-coded labels, barcoding systems for medications, and EMR alerts that reduce the chance of missed steps–simple ideas that protect patients and staff from preventable harm.

We often think of mistake-proofing as a physical device, but it can be as simple as a checklist, a pop-up alert, or even peer review. The principle is the same: help people succeed by making the right way the easy way.

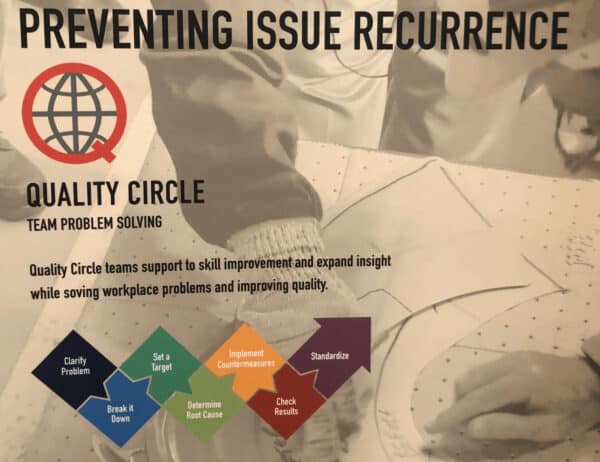

Developing People Through Quality Circles

Another display described the “quality circle” approach (something that dates back to the days of Toyota Quality Management and it's alive and well in Japan):

The quality circle process is more than a flowchart–it's a structured way to build problem-solving capability at every level. At Toyota, and in organizations that embrace daily Kaizen, it's not about perfection–it's about developing people through cycles of experimentation. That idea is echoed in many of the Kaizen programs I've written about, where front-line teams identify and test improvements that matter to them and their customers.

In my visits to hospitals in Japan and the U.S., I've seen how this approach empowers frontline staff to take ownership of problems and solutions alike. It's not about suggestion boxes–it's about structured support for improvement cycles grounded in real work.

The steps are:

- Clarify Problem

- Break it Down

- Set a Target

- Determine Root Cause

- Implement Countermeasures

- Check Results

- Standardize

Here's a blog post about quality circles in Japan:

How Toyota's Culture of Learning Inspires Our Own

There was so much cool stuff to take in at the Toyota Experience Center. I hope you can get an invitation (or maybe it will be open to the public, at some point, like the similar center in Japan is).

Toyota's Experience Center doesn't just showcase the company's past–it reinforces how TPS and Lean leadership are still evolving, driven by humility, experimentation, and respect for people.

Whether you're walking a factory floor, leading a team, or solving problems in an office, the principles on display here–standardized work, Kaizen, mistake-proofing, problem-solving at the root–are the same foundations I've written about in The Mistakes That Make Us and my other books. They're not tools for engineers; they're habits of culture that help us learn, adapt, and thrive together. If you're looking to build a resilient organization, there's no better place to start than here.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.

Great article, and what an amazing experience! I believe the lessons you shared are great, particularly the point “don’t assume your reputation will carry you through a crisis”. Often times large companies can consider themselves too big to fail, and believe their name will carry them through different problems. Toyota does a wonderful job sharing their knowledge, and insight into their practices. The VR tour of their facility in Ontario is a great way to give visitors a “real life” experience more so than even if they went in person (not being able to see certain areas of the factory). Thank you for sharing.