Kaizen isn't limited to factories or hospitals–it shows up anywhere people care about doing work better. During multiple visits to Garrison Brothers Distillery, I've seen how small, practical improvements to a hands-on bourbon bottling process made the work safer, easier, and more reliable. This post highlights those changes and why they're a great example of Kaizen in action.

I've blogged about Garrison Brothers and my stint as a bottling line volunteer before:

Kaizen on the Bottling Line: Learning by Doing

In that post, I shared pictures of me working to dip bottles of bourbon into a sealing wax. I was wearing a winter coat because it was February in Texas and there was a bit of snow and ice that week.

When I was back there recently, I saw some additional improvements that seem like “Kaizen” to me.

The Original Bourbon Bottle Dipping Process

In one photo from my earlier post, you can see me dipping a bottle:

And here's that shows the tool we use to press a star into the top of the bottle:

I've been visiting or volunteering at Garrison Brothers for more than five years. Garrison Brothers has released new and innovative bourbons over time, but the bottling process remained pretty unchanged.

In that earlier blog post, I wrote about how I applied some personal “kaizen” or an improvement that made my work easier and improved quality.

When I was there a few weeks ago, I noticed that they had made some further improvements in the bottle dipping area. I always love to see improvement!

Here is somebody else dipping a bottle (and I was able to use this improved process too):

What's changed? Other than the fact they are dipping half bottles into black wax that day?

Kaizen Improvements to Safety, Quality, and Ergonomics

Small Changes That Reduced Risk and Made Work Easier

1) There's a red template over the wax dipping pot. The template is big enough to dip the bottle in, but it now helps prevent things from being dropped in there. You don't want to drop your phone or that star stamper into the wax. And, you don't want to reflexively start to reach in there if you've dropped something, so it reduces some risk and improves safety.

2) The dippers now have to wear glasses, to help prevent wax from splashing up in somebody's eye if they drop something. When I was there a few weeks ago, one volunteer is a retired safety professional and he thought that the glasses might be overkill since they've now added the template. And, he pointed out that safety glasses are meant to protect against impact. Goggles are what you use to protect against splashes.

3) Dippers also wear protective arm guards, which were a bit uncomfortable and, again, the retired safety professional asked if that was also overkill since the risk of splashing is much lower now.

4) Dippers now also wear gloves, which I found to really help improve my grip on the bottle, which is probably good from an ergonomics perspective since you might not need to grip the bottle with as much squeezing force. And I bet you're less likely to drop a bottle.

5) The star stampers are now hung on a cable above the bottling line. This helps prevent them from, you guessed it, being dropped on the wax (or the floor). You can reach up and pull one down from its retractable cord. You can also tug on it so it stays closer to the height you need, reducing the need to reach up all the way each time.

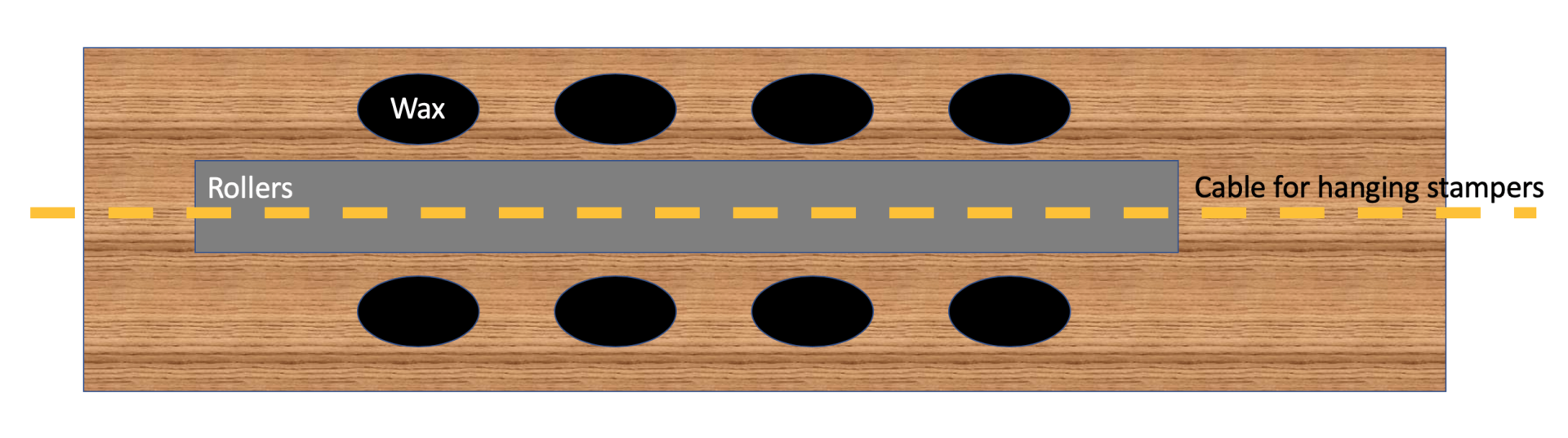

See this annotated photo:

Now, we're not visiting Garrison Brothers because they are a “Lean distillery” by any means. But it's fun to look at a process and to talk to people who are both innovating and improving.

Kaizen Upon Kaizen: Improving the Improvement

I had one additional Kaizen suggestion for the hanging stampers. In the practice of Kaizen, we sometimes make one improve and then, in the initial testing, find another way to make the improvement even more improved. In our book Healthcare Kaizen, Joe Swartz and I wrote about how his health system says “kaizen upon kaizen.”

When an Improvement Creates a New Problem

Since the stampers for both sides of the table were all hanging from a central cable that was centered over the bottling line, those hanging stampers sometimes got in the way of the flow of bottles on the rollers, as I've tried to illustrate below:

I talked to the bottling area manager and he thought my suggestion of having TWO cables — one for each side of the bottling line — made sense and would be relatively easy and inexpensive to implement.

I think these are great illustrations of “kaizen” improvements and potential kaizens.

What This Bourbon Bottling Example Teaches About Kaizen

Kaizen is meant to:

- Be done by the people who are doing the work

- Make your work safer and easier

- Improve quality

- Make it harder to make mistakes

I think Garrison Brothers is doing all of that.

Tradeoffs, Constraints, and the Reality of Continuous Improvement

One downside of the the red covers (I forgot to draw them in my mockup… because I am still getting used to that change) is that it would be harder for me to do my “silver wax stirring kaizen” that helps smooth out the wax to prevent bubbles or drips, as I show in this video:

A Final Reflection: What Kaizen Really Looks Like in Practice

This small slice of work at the Garrison Brothers bourbon bottling line is a reminder that Kaizen doesn't require a formal Lean program, consultants, or Japanese terminology. It requires people who notice problems, care about safety and quality, and feel empowered to speak up and make their work easier and better.

What's especially powerful here is that the improvements weren't driven by abstract metrics or management mandates. They emerged directly from the work itself–wax splashes, awkward reaches, dropped tools, and subtle flow disruptions that only become visible when you're standing at the line. That's where meaningful improvement always starts.

This example also shows why Kaizen is never “done.” One improvement can reveal the next opportunity. Safety countermeasures introduce new constraints. Ergonomic fixes create new tradeoffs. That's not failure–that's learning. It's Kaizen upon Kaizen, exactly as it should be.

Whether you're working in manufacturing, healthcare, food production, or knowledge work, the lesson holds:

- Improvement is most effective when done by the people doing the work

- Small, low-cost changes can deliver outsized benefits

- Respect for people and curiosity about problems go hand in hand

You don't have to be a “Lean organization” to practice Kaizen. You just have to be willing to look closely at the work, listen to the people doing it, and keep asking,

“How could this be safer, easier, or better?”

That mindset–more than any tool or framework–is what sustains continuous improvement over time.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.

You are excited, but probably not as excited as David. However, he was a little disappointed when he realized that the TSA will prevent him from bringing back any samples!

Hi Karen – David should be able to bring samples back if he checks his suitcase at the airport…

You had me at bourbon…Great post!