Last week, I received a few questions from somebody at a hospital system and I thought I'd address one of them here. If you have questions you'd like me to answer (or at least try to answer) in a blog post or a podcast, contact me.

Question:

“Can you suggest any “quick wins” to get staff engaged in a Lean culture?”

I think this is a great strategy. Rather than telling people that Lean is a good thing, demonstrate that in real life.

I can't directly answer the question about what the “quick wins” might be in a particular hospital or a department.

The “quick win” I can suggest is asking the staff what they think some “quick wins” would be. That's the classic advice for how to start with the “Kaizen” approach to improvement and how to start building a culture of continuous improvement.

Ask people what bugs them. What gets in the way of you doing your work? What frustrates you? What would allow you to provide ideal patient care?

Then, ask “what can WE fix?”

You're not asking them to dump work on the department manager or director. You're not asking them to give suggestions to executives or other departments.

QUICK win. What can we fix today?

Hear Mark read this post (subscribe to the podcast):

I often tell the story of a primary care clinic that I was coaching. We were trying to figure how to engage the physicians in the Lean improvement process. We asked one podiatrist about problems that he saw and he couldn't really identify anything.

People can become blind to waste when it's a daily occurrence. It's not waste, it's work.

A nurse and a medical assistant shadowed the podiatrist (with his permission) to look for barriers in his daily work (NOT to tell him how to do his job better).

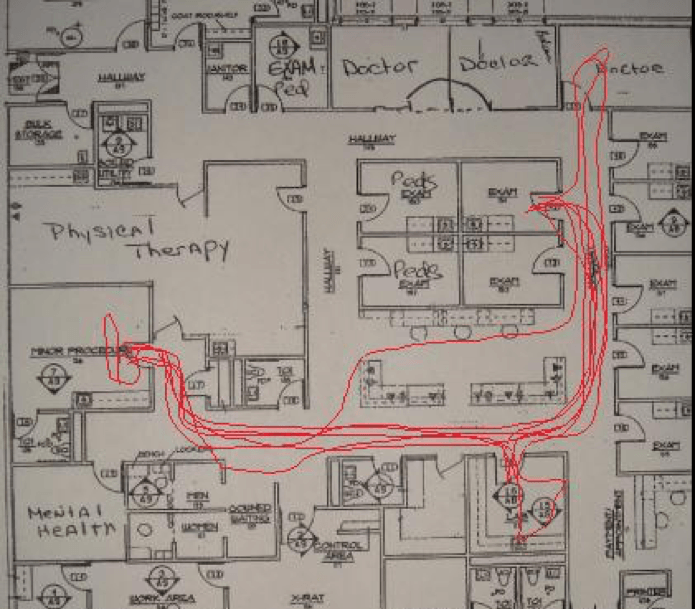

They drew this “spaghetti diagram” that showed where he had to walk in the clinic.

It was 670 feet of walking and motion. The patient was left waiting in the exam room. The podiatrist was walking around for 10 minutes.

Why?

Not because he was lazy or a bad doctor!

He was doing his best… fighting through a bad system. That bad system included the clinic being disorganized and supplies and equipment not being stored in convenient, consistent places. He was “hunting and gathering” what he needed to do a simple toenail procedure (one that had a value-added time of about 30 seconds).

Gauze… scalpel… freeze spray. Why was it so hard for him to find what he needed to provide patient care?

He worked in four different clinics on four different days of the week. Why was each clinic set up differently?

Once the team and I showed him the spaghetti diagram, it opened his eyes. Before, all of that walking around was seen as “work.” It was “necessary.” He viewed it as “doing his job.”

But, it didn't have to be that way!

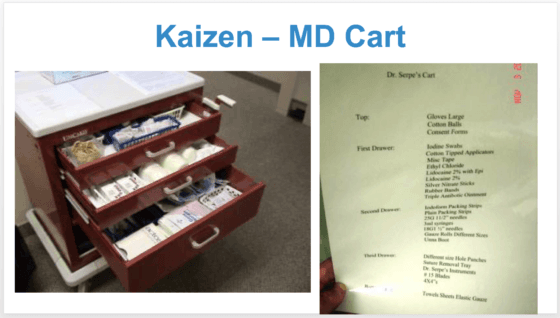

What was the quick win? The team in the clinic put together a cart that contained had all of the podiatry supplies that were needed. Even before Dr. Atul Gawande's book The Checklist Manifesto became popular, they created a checklist that could be used to make sure the cart was restocked the night before the doctor was coming. It was a form of “standardized work.”

Here's a photo of that cart and checklist:

The doctor LOVED the cart. They parked it just outside the two exam rooms that he would use. It saved so much time for him. It meant the patients didn't wait as long. He could actually start seeing more patients per day, which was good for everybody involved (shorter waiting times, more revenue for the clinic and the doctor).

He went, within the course of a week, from:

- Not noticing the waste

- Realizing things could be better

- Recognizing that Lean (and Kaizen) was something that could make his job easier

The podiatrist got a “quick win.” He was engaged.

He then asked, “How quickly can I get one of those carts at the other three clinics?!?!?!?”

At first, the clinic team created a solution for him (out of service to him). Solving a problem for somebody is often a great way to get them to directly participate in identifying and solving problems.

So, don't just train people about what Lean is. Help them improve. Solve problems that affect their daily work lives. Create a better system.

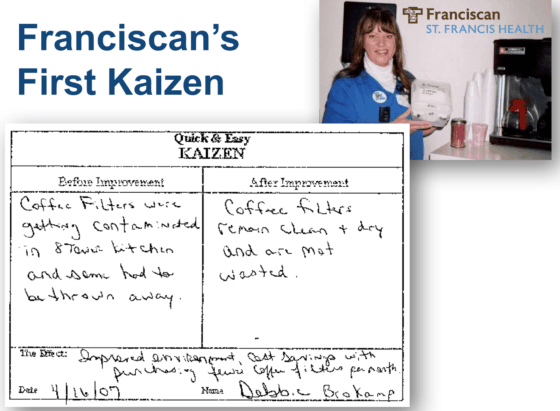

The first Kaizen implemented at my Healthcare Kaizen co-author's health system was a simple “quick win” identified by a member of the housekeeping staff:

What was her quick win? A plastic container to keep coffee filters in.

This didn't require an A3 or root cause analysis. It didn't require a project charter or a capital improvement request. It wasn't a Rapid Improvement Event. It was about as simple as a “just do it” gets. It was a quick win.

That small improvement helped set the stage for about 30,000 more that have been implemented and document at Franciscan St. Francis Health. Some of their ideas, about 10%, save money. Some of those save large amounts of money.

A related question that I often get:

“How do we use Kaizen to reduce costs?”

Sometimes we get better results (more cost savings) by not demanding that every improvement directly save money. We don't ask for an ROI analysis or a particular ROI threshold for each improvement. We're trying to build a culture. That means finding a way to say “yes” to virtually every improvement idea. Franciscan has documented millions of dollars of hard cost savings (verified by finance).

This demonstrates the concepts of “Obliquity” or the indirect path toward a goal, as I've blogged about before:

What “quick wins” can you help people find this week? What do you think about this? Post a comment below or join the ongoing discussion on LinkedIn on this question and topic.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Comment from Twitter:

Fix what bugs you as Paul Akers talks about is a great way to get “quick wins” and get staff engaged. However, it must be a continuous effort to move closer to culture change. If we only periodically make improvements or do episodic improvements during events or projects and the rest of the time it’s business as usual then according to neuroscience what we’re actually teaching is business as usual.

Of course. “Quick wins” should be the starting point for ongoing continuous improvement. That requires that managers and other leaders engage people on a continuous basis.

Some quick wins followed by nothing will just breed more cynicism.

Same is true with “kaizen events” — they were supposed to provide relatively “quick wins” that are bigger impact in a weeklong event. But, many organizations never bridged the gap from episodic events to daily continuous improvement, as had been the intent of the original consultants on this.

ThedaCare is an example of a health system that realized corporate quick wins (rapid improvement events) weren’t enough, so they now aim to get 80% of their improvement from smaller improvements.

A small “just do it” is a quicker quick win than a weeklong event. It’s easier to do and less risky. But, there’s a time and a place for events as part of that culture of continuous improvement.

I can’t agree more Mark. Why is it that very few organizations grasp the concept that 80% of an organization’s performance improvement potential lies in front-line ideas as noted by in the Idea-Driven Organization?

ThedaCare gets it. Franciscan St. Francis Health gets it. Some others get it.

Could be lack of awareness and lack of education. That’s why I bang the drum for Kaizen as daily continuous improvement.

Even if people learn about this, do they not believe it? Does ego get in the way? “The way we’ve always done it” gets in the way?

Ego does get in the way. “The way we’ve always done it” also gets in the way. Just last week I gave a presentation on Toyota Kata hoping I could persuade the use of TK with current and future clients. I outlined how it’s a structured way to create a culture of continuous learning and improvement at all levels, how it’s a way of thinking and managing, with a need to experiment in order to learn, and how it seeks to build the context within which lean tools are applied. Even though some liked elements of it, I was tactfully informed of all the reasons it will not work.

Sam – was it simply a matter of ego or other factors?

It sounds like you were pitching TK as a solution.

Did the group agree that there was a problem to solve through TK (or any other method)?

Mark, to give you some context, my boss approached emailed me and said I should look into Toyota Kata. He said it sounds like my model for coaching and questioning. I informed him that I was familiar with TK and have integrated kata mindset into my coaching approach. I then put some slides together from Mike Rother’s site introducing Toyota Kata which I used to present to him and other senior consultants from my company. I was pitching what is TK, why use TK, The 4-Steps of the Improvement Kata Model, and the artifacts (learner’s storyboard, PDCA cycles record, The 5-Question Coaching Card). The group did agree that it could solve several problems, such as breaking down large challenges into small targets, developing problem-solving capabilities at a more rapid pace, a better approach to develop people, etc. However, they listed off reason why it would not work as laid out in a purist form. The compromise was to continue to integrate kata mindset into the coaching approach. Reflecting after I was reminded of John Shook’s famous quote, “It’s easier to act your way to a new way of thinking than to think your way to a new way of acting.”

What do you mean by “a purist form?”

What I mean by purist form is managers acting as coaches to teach systematic, scientific way of thinking and acting. The Coach (manager) provides corrective inputs to ensure that the Learner practices the new routines the right way. This would imply that before they can coach the Improvement Kata, managers need to practice the Improvement Kata themselves. Ultimately, managers have to change the way they lead.

Ok thanks. It’s important to learn by doing so you can even possible get to a point of training or coaching others to learn by doing.