I want to express my gratitude to Joe Swartz and his colleagues at Franciscan St. Francis Health for hosting our “Kaizen Live!” event. Yesterday was the first full day, and everybody (24 attendees) will be back this morning to continue the learning and discussion.

The Franciscan story and our other Kaizen experiences are documented in our Healthcare Kaizen books.

One of the things I learned (or was reminded of) yesterday is that it requires time and patience to build a culture of continuous improvement. Joe and the Franciscan leaders pretty consistently describe stories in departments that go like this:

- Leaders introduce Kaizen

- Staff shrug and say, “Oh, here's one more thing to do”

- The leaders are persistent… and keep asking for ideas

- The leaders help staff, recognize them…. more consistent effort every day

- Some staff participate

- Leaders continue their consistent behaviors

- After six months or maybe a year, things really take off. Kaizen has become “the way we think and the way we do things around here.”

Changing the culture in an organization isn't easy. It's not like flipping a light switch.

But, after time, the folks at Franciscan say things like, “Our brains have changed” and “This is just how we think now.”

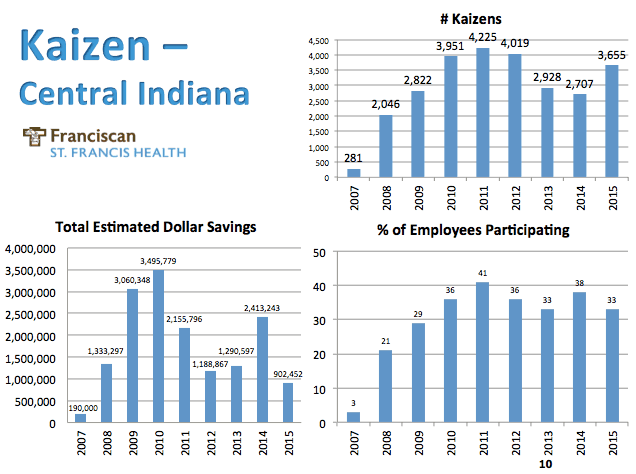

Kaizen at Franciscan isn't just about solving problems… it's about developing people. They've implemented and documented more than 27,000 improvements since 2007… and there are countless others that staff would admit have not been documented.

It's really special to see this culture in place. The key discussions then, for our attendees, are about how to create this culture. How can you get from here to there? It's easier to see “what good looks like” than it is to get started on that path (and to keep going). If you're willing to take that journey, Joe and I would love to help.

Changing an organization's culture isn't like flipping a light switch. It's more like tending a garden–steady, deliberate, and rooted in care. Over time, as Joe often says, “our brains change.” At Franciscan, people don't see Kaizen as an extra task; it's simply how they work and how they learn.

Since 2007, they've implemented and documented more than 27,000 improvements. Each one represents not just a better process, but a person who felt safe and supported enough to speak up with an idea. Many more improvements happen quietly and never make it into the system–but they still make work better.

It's genuinely inspiring to witness a culture where improvement is part of daily life. The most valuable question for our group wasn't what Franciscan does–it was how they've made it part of who they are. How do you get from “introducing Kaizen” to “this is just how we think”? Seeing “what good looks like” helps us imagine that path more clearly. And for those who are ready to take the journey, Joe and I are always eager to help.

Kickoff and Welcome

Our Kaizen Live! group included twenty-four participants from across the United States and the Netherlands, representing both healthcare and manufacturing organizations. The first morning began with an unmistakable sense of anticipation–everyone eager to see how daily continuous improvement works in practice.

We opened with remarks from Joe Swartz, Franciscan's Director of Business Transformation, and Sister Martha Ann, one of the hospital's earliest Kaizen champions. Between them, they set a tone of humility and purpose. Joe reminded us that Franciscan's success wasn't a sudden breakthrough but a long, patient accumulation of small steps. Sister Martha Ann spoke about how Kaizen reflects the hospital's faith-based mission: continuous improvement as an act of respect and service.

Together, they framed Kaizen not as a program or initiative, but as a way to live the organization's values every day.

Data and Lessons Learned

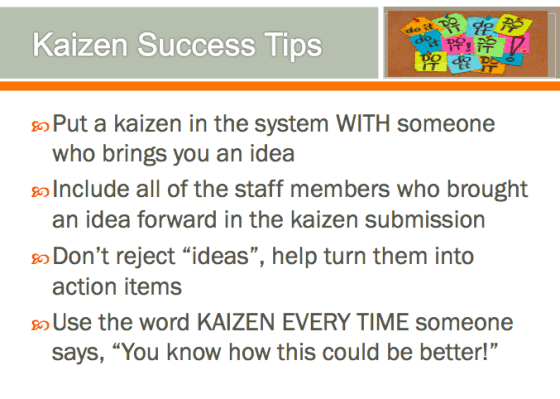

Joe shared several charts and data sets illustrating how the organization's Kaizen activity has grown since 2007. The 27,000 documented improvements reflect thousands of people contributing ideas, but what matters more than the number is the trajectory–the steady climb built on consistency.

Early on, leaders sometimes had to coax ideas from reluctant teams. Now, in many areas, managers are working hard just to keep up with the flow of ideas coming in. Some departments average several implemented improvements per person each year.

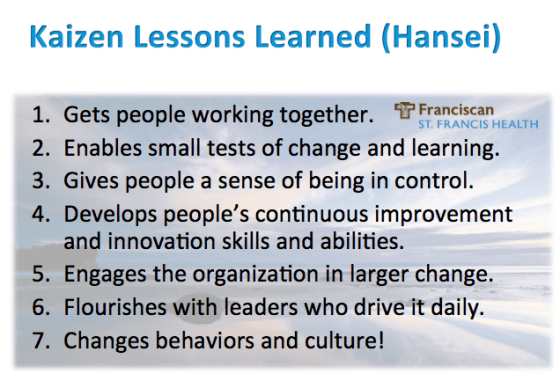

Joe summarized Franciscan's hard-earned lessons:

- Culture change happens in years, not months.

- Leadership behavior matters more than leadership slogans.

- Recognition fuels momentum–thank people visibly and often.

- Improvement grows fastest when leaders replace fear with curiosity.

He also shared impact data: units actively practicing Kaizen report higher engagement and lower turnover.

“Kaizen doesn't just improve our processes,” he said, “it improves our relationships.”

Frontline Story: Nursing and Kaizen

Matt Pierce, now a Nursing Director, told his own Kaizen story. Years ago, as a bedside RN, he was skeptical. “It felt like one more thing to do,” he admitted. But as he began solving problems with his team–rearranging supply locations, streamlining handoffs, eliminating small frustrations–he saw the change in morale. Over time, his curiosity deepened. He trained as a Green Belt and later a Black Belt, and today he leads a department where staff contribute and implement ideas routinely.

One of Matt's favorite examples was a simple reorganization of a patient-prep area that cut setup time by 20 percent. Small wins like that, he said, change how people see their work:

“When we fix problems ourselves, we feel proud. When someone fixes them for us, we just feel managed.”

Gemba Visit: Endoscopy Department

Before touring the Endoscopy Department, its leaders and nurses described how Kaizen has become part of their routine. Their unit alone has implemented hundreds of improvements, from small labeling changes to layout redesigns that save minutes per case. During the Gemba walk, we saw color-coded drawers, standardized kits, and simple visual cues that eliminated searching and waiting.

One nurse shared how modifying the cleaning process for endoscopes reduced turnaround time by 25 percent while improving safety. Every idea was displayed on their visual board, with metrics showing time saved or errors prevented.

“We don't wait for someone else to fix things anymore,” one team member said. “We fix them together.”

Leadership Panel: Sustaining a Culture of Improvement

A panel of Franciscan leaders discussed what it takes to sustain Kaizen. Each echoed a similar pattern: the first few months bring skepticism, but steady leadership changes the story. After about six months to a year, participation grows naturally.

“Once people believe the leaders aren't giving up,” one said, “they start giving their best ideas.”

Leaders measure idea flow and implementation rates, but they treat those numbers as learning signals, not performance targets. The real goal is engagement–building confidence that every voice matters.

Pharmacy Gemba: Visual Management and Flow

In the pharmacy, Kaizen had improved medication safety and efficiency. Through visual management, clearer labeling, and workspace redesign, the team cut wasted motion and reduced search time by 30 percent. One technician described how a labeling improvement prevented multiple near-misses. Another shared how relocating high-use items saved the department roughly 40 minutes per shift.

Their visual board tracked error trends and cycle times, proving that disciplined small changes compound into real results.

Perioperative Services: Turning Complaints into Improvements

The Director of Perioperative Services described how her team built its own internal Kaizen tracking system long before commercial software existed. This homegrown database lets staff log, track, and share ideas across the hospital. Their data show an 85 percent implementation rate, with most ideas completed within weeks rather than months.

Her closing slide captured her philosophy perfectly: “Every complaint hides a potential improvement.” She told how a nurse's repeated frustration about instrument delays became the starting point for a Kaizen that cut turnover time by 20 percent and improved teamwork.

“We used to dread complaints,” she said. “Now we see them as data.”

Her key lessons:

Reflections and Takeaways

By the end of the first day, our group had witnessed something that numbers alone can't capture–a culture where improvement is instinctive. The statistics were impressive, but the real story was human: empowered staff, patient-centered results, and leaders who coach instead of command.

At Franciscan, continuous improvement isn't an event or a workshop–it's part of the daily rhythm of care. And that, more than anything, is what “good” looks like.

As one participant put it during our closing reflection,

“Kaizen here isn't about fixing problems faster–it's about thinking differently together.”

Seeing Kaizen alive at Franciscan reminded everyone that this kind of culture isn't the result of a single project, tool, or training session. It's the outcome of countless conversations, experiments, and leadership moments repeated over time. The work is never “done,” but it becomes deeply rewarding as people begin to see themselves not just as problem solvers, but as improvers by habit.

If you're willing to take that journey, Joe and I would love to help.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

[…] Wednesday’s blog post was mostly a collection of tweets about the “Kaizen Live!” workshop at Franciscan St. Francis Health. Check it out. Those tweets aren’t repeated here. […]