I was quoted in two articles that appeared in “Today's Hospitalist”:

- “Discharging Mr. Wood: Time to get serious about waste” and

- “Standardized work: Improving quality by reducing practice variation.”

Reducing Waste

The author, David A. Frenz, MD, points out that it's a “collective delusion” that the U.S. spending so much more on healthcare leads to safer or higher quality care.

People are waking up to the fact that there is too much waste in healthcare. We have poorly designed systems and processes — it's not the fault of individuals, nor is the waste due to a lack of clinical expertise or a lack of technology.

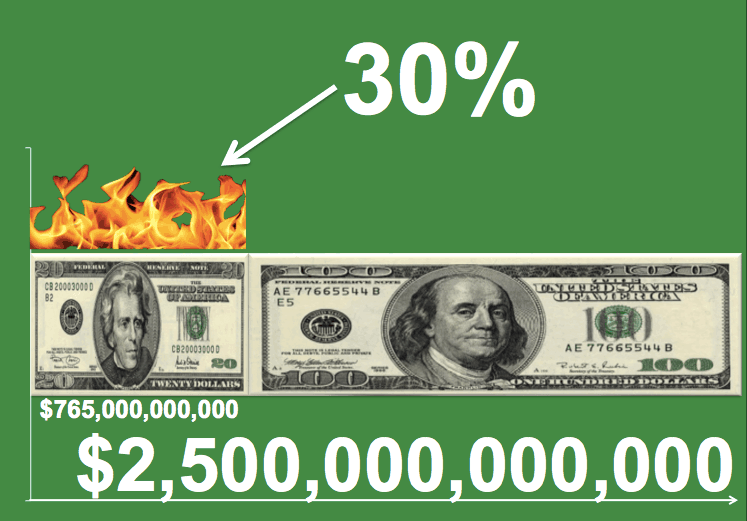

The Institute of Medicine estimates that about a third of our healthcare spending is unnecessary — over $750 billion a year.

See my illustration, below, of this from a webinar that I did for Gemba Academy on waste.

See the first article for a table that shows the “eight types of waste” (using the TIMWOOD acronym) with examples that are relevant to hospitalists.

As the article correctly points out, the way to reduce waste is not about asking hospitalists to “scrimp” on “CBCs [blood test] and paper clips.” Reducing waste doesn't mean rationing necessary care; it means figuring out how to reduce unnecessary care.

Dr. Frenz encourages his fellow hospitalists to stop fighting fires and to stop taking actions that don't get to the root cause of a patient's problems.

From the article:

“Lean calls for a radical change in perspective. Mr. Graban writes, “Employees and leaders often think their job, or the value they bring to an organization, is their ability to deal with problems. … Instead of pointing at workarounds and heroic measures as ‘our job,' we have to look at waste as something to reduce or eliminate, so we can spend more time doing our real work–caring for patients.”

Dr. Frenz also says that hospitalists should look beyond just doing clinical improvement projects. They should also look to get involved in operational improvement initiatives, saying:

“Going back to the IOM report, hospitalists own large chunks of two categories–unnecessary services and inefficiently delivered services– that account for 44% of all that waste. Reducing that by just 1% would save $4 billion per year and thousands for your hospital.”

Hospitalists can be the beneficiary of Lean improvements and they can also play an important role in improving operations. Hospitalists can work to improve communication and processes to help reduce medication errors and other types of patient harm, as well as helping get patients discharged without unnecessary (and frustrating) delays.

A few years ago, I collaborated on a journal article about Lean and hospitalists, if you have access.

Hear Mark read this post (learn more):

Standardized Work

In the second article, from the April edition, Dr. Frenz talks about the need to reduce variation. I'd be the first to say that we shouldn't standardize for the sake of standardizing. Nor do I think we should reduce variation for the sake of reducing variation. There has to be a real problem to solve by either increasing standardization or reducing variation.

Dr. Frenz says:

“Practice variation is literally killing our patients”

Well that's a pretty powerful problem statement.

How can we prevent harm and death for patients? Dr. Frenz uses checklists as an example of standardized work. And we agree, as he writes:

Doctors are notoriously independent and recoil from anything that smacks of “cookbook medicine.” Patients aren't Toyotas and we won't be reduced to automatons. There's just way too much texture and subtlety–which is why medicine is an art and profession.

And people who advocate for translating Toyota's methods into health care agree. Mark Graban, author of “Lean Hospitals,” points out that our reluctance stems from a linguistic confusion: “Standard can sound like an absolute, a method with zero variation or zero flexibility. It starts sounding like the word identical, which makes employees concerned that they are being turned into robots.”

But as he further explains, “Standardized work is the plan that frees us from having to make hundreds of small decisions throughout our day, thus freeing brain capacity and reserving energy to deal with the smaller number of more important decisions that arise.”

How do you see the role of standardized work in healthcare? Have you been able to standardize the things that matter without going overboard and irritating or alienating people with standardization that goes too far or does not serve a purpose?

What are hospitalists doing in your hospital to drive your Lean transformation efforts and, more importantly, improve patient care?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Yes, many processes in healthcare can be standardized to reduce waste and they should be. This is true of both clinical care and operations.

As you noted, by far the biggest wastes outside of administering payments is over-utilization and variation in care (not even including oft-neglected diagnostic processes). It is ironic that while many Lean efforts put extraordinary effort into eliminating waste in “paper clips and cbcs”, they totally ignore the bigger waste in clinical variation as you pointed out. The danger to some Lean efforts is that until you take on over-utilization and clinical variation you may not be generating enough benefits to justify that Lean program office.

Lastly, I think we would do well to just drop the term “standardized work” when engaging clinicians. I think a better term is “standardized decision making”. Different than making Toyotas where a focus is to eliminate internal process decision making, for many diseases the disease management process essentially is all about internal decision making. This just may be nuanced phraseology to some, but using terms like standardized decision making or clinical algorithms is much more appealing to clinicians than talking about standardized work.

Yes.Something is best understood when it is spoken in their own language.

What is actually needed is to develop a standard work that defines the Standardised decision making of the clinicians in the best possible manner for an effective and error free internal decisions.

Something as simple as how quickly discharge summaries are completed by hospitalists and provided to the primary care physician can have a positive ripple effect, cutting down on requests to HIM departments, empowering PCPs to have a more informed transitional care visit, complete with a med rec etc….

Great article, Mark. The inefficiencies of delivering patient services resonates with me. So does reduction of waste to allow reallocation of resources to get at the root causes of patient illness sooner in the process.

Hi Mark, just now seeing this post and wanted to share that since your visit to Hillcrest Hospital (Cleveland Clinic) earlier this year, we have launched a culture of improvement model area with our team of hospitalists! We are using the Cleveland Clinic Improvement Model to identify what matters most to our physicians and their patients. The 8 waste examples listed in the first article really hit home; some of our early improvement efforts are focused on these wastes. Perhaps there will be an opportunity to share more with you as we progress on this journey!

Thanks for the update. I still plan on writing about my visit to Hillcrest. I hope to be able to come back sometime to learn more about what you’re doing!