Note: I'll be flying back from Tokyo most of the day Monday. With the international date line and the time zone differences, I depart Tokyo about 7 PM local time and land in Texas at 4 PM local time — going back in time three hours! :-)

I'll be sharing many reflections and stories from Japan in future posts. Today's post takes a look at lessons learned from an American facility – the famed NUMMI joint venture plant…

I'm weird. Well, regular readers of the blog know that. One particular weird thing is my affinity for the NUMMI plant that ran as a joint venture between Toyota and GM from 1984 to 2010. The weird thing is that I have an eBay alert in case something interesting from the plant's past comes up for sale. No, I haven't bought the NUMMI edition of Monopoly.

I did manage to buy a book that was published by NUMMI to celebrate their 10th anniversary. “10 Years of Quality & Teamwork” is the title.

Here is the cover and I'll share a few things that caught my attention inside. It's interesting to think through this book in the context of :

- Tesla (the current owners of the building – see my past blog post)

- Healthcare organizations

The introductory letters came Toyota's president Tatsuro Toyoda, who served as the first NUMMI plant president and passed away recently, and GM CEO John F. Smith, Jr. Click the image for a larger view.

Toyoda said the plant is “a shining example of what people, working together, can achieve” when you have “mutually beneficial goals that serve the best interests of everyone involved.” He focused on “cooperation and quality.”

The lens of the GM CEO is interesting. He refers to “state-of-the-art lean manufacturing,” but focuses more on the plant being “more efficient and more responsive to customer needs and desire.” Sure, he mentions quality but also references the plant's “formula for world-class efficiency.” I can't help but notice he mentioned efficiency before quality.

Quality and efficiency do go hand in hand. Smith describes the formula as “giving people the opportunity to work together as a team, and make decisions on their own, on the plant floor.” That's the “best way to build a winning organization.” Yet, GM struggled to spread that spirit across the company, as “This American Life” documented.

Smith also had a different perspective than former CEO Roger Smith who spent (wasted?) billions on his dreams of a “lights-out factory.” Tesla CEO Elon Musk seems to share that vision of automation. Smith was either wrong or just head of his time. See some past blog posts on this topic:

GM's CEO Roger Smith Thought Toyota Had Magic, But This Was the “Secret”

The Coming Auto Industry Battle: Toyota's People vs. Tesla's Robots?

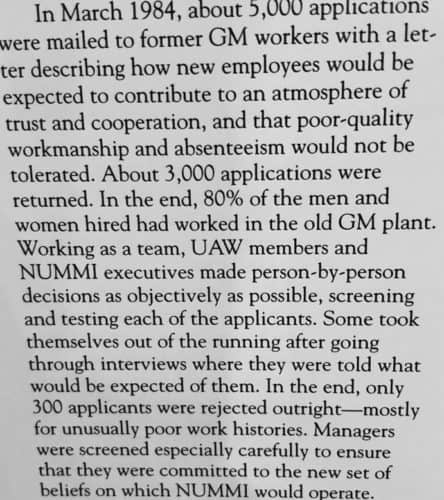

The book talks about the process for selecting and hiring NUMMI employees from the poor of former GM/UAW employees from the failed GM Fremont plant that used to occupy the building.

60% of the laid-off employees applied for a job at NUMMI. 80% of those hired at NUMMI were from the old GM plant. “Only 300 applicants were rejected out outright – mostly for unusually poor work histories.”

The old GM way was to blame the workers for everything. Sure, a small percentage were unacceptable to Toyota. But they made NUMMI a success with what had previously been considered “bad” workers.

The key is having the right managers, as they were screened “especially carefully to ensure they were committed to the new set of beliefs on which NUMMI would operate.”

When I worked at GM just a few years later, that plant did NOT have “common goals of maintaining and improving the quality of life” for employees and our families.

I love the quote from George Nano, a UAW leader:

“Show me another compay that says it's committed to providing employees with a voice in their own destiny or recognizing the full worth and dignity of its employees. Now that's something!”

Is that part of the Tesla playbook – the full worth and dignity of its employees? Is it part of a typical hospital's approach and culture?

The book also talks about the “common destiny” that everyone is in the same boat.

In too many hospitals, workers (and some managers) are viewed as a cost to be managed (or cut) instead of having what should be a very strong sense of alignment and a shared purpose.

The book talks about “mutual respect:”

The contract said “no one will be laid off unless the long-term viability of the company is threatened.”

Compare that to hospitals that are relatively quick to lay people off when their margin is slightly threatened (a different threshold than SURVIVAL).

The NUMMI contract also said “before anyone is laid off, executives will take reductions in salaries.” That's a very Japanese approach, as I've heard about in trips to Japan.

NUMMI management was “strengthening the bonds of trust” by fulfilling that promise on four separate occasions.

The book talks about valuing workers as “an asset rather than being regarded as a cost which can be trimmed during downturns.”

Toyota has followed this same philosophy and approach in the U.S. as they've run their own plants. See previous blog posts where I've compared the Toyota and GM approaches in recent years. GM sure didn't learn all of the lessons they could have from NUMMI, did they?

GM Blames Layoffs on the Japan Earthquake and JIT; Should Instead Look in Mirror

NUMMI's president at the time, Iwao Itoh, said:

Does Tesla and your typical hospital give credit to the “brainpower” and “full participation” of their employees? Or, is success the result of brilliant executives… and failure something that gets blamed on workers?

The book directly addresses the need for managers to respect their employees, with a quote from Gary Convis:

GM's CEO valued “world-class efficiency.” But, it was not yet the GM norm to “turn to people on the line” and to “work with our people, to listen to them for their ideas, and work as managers to support them.”

When I worked at a GM plant in 1995, the norm was for managers to blame workers for everything. That changed once we got a new plant manager with a NUMMI background in 1996.

Convis said, “It has everything to do with respecting the team member because without their full support, you're actually dead.” I agree that's a “far cry from how many American auto plants have been managed.

The book addresses avoiding blame.

“When something goes wrong on the line most managers go looking for a culprit – someone who is slacking off or doing something wrong.” That's the GM playbook I saw in my time there.

“NUMMI's managers have learned to look for the problem rather than someone to blame. Most of them have learned to trust that their team members are doing their best.”

You can see the strong influence of W. Edwards Deming, who taught that most people come to work to do good work.

Nobody's perfect — as they admit “we slip sometimes.” I appreciate that humlity. I'm sure they saw it as an unfortunate gap that about 25% of NUMMI team members did NOT say that management treats them with respect.

The book talks about how “academics” misunderstood NUMMI, thinking that “NUMMI's open parking and cafeteria and its organization with fewer levels of management were ‘Japanese management.'”

The book predicted a “bright future,” which was true until the “great recession” and GM's bankruptcy led to the dissolution of the joint venture with Toyota.

I hope this message comes through loud and clear:

“Lean” does not mean “mean.”

I hope that's true in your organization's “Lean” approach. It's about mutual respect, not telling people what to do. If you don't have a sense of “we are all in the same boat,” you might not have “a bright future ahead” either. Yet, too many leaders and organizations refuse to learn these lessons from over 20 years ago.

Lean means mutual respect and engaging everybody in improvement.

The book said, “Every year, thousands of suggestions are submitted. Since the program began, over 78,500 suggestions have been submitted by team members.” I bet a vast majority of those were implemented. The plant also started a “Quality Circle” program in 1991. They called the approach “Problem Solving Circles” and participation was growing.

Was the NUMMI plant perfect? No – they admit as much in a celebratory book.

The lessons about what it means to be a truly Lean organization are out there. We need to look and be willing to learn, as do our leaders and executives.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Comment from LinkedIn:

Dario Ricci

PMP® Project management ICT

very interesting article. The most inspiring part to me is in the picture below: NO ONE, in the period of reduction of production lose his or her job, but everyone was involved in RETRAINING and PROBLEM SOLVENG of THE NEW PRODUCTION SYSTEM. #Process Engineering, #Change management and #Commitmment were the key of this stunning success…

My reply:

Some healthcare organizations have gotten that message… but some again started laying off people in an effort to “cut costs.” It’s easy for a hospital to have a “no layoffs policy” when times are good. Toyota holds to that pledge even when times are bad

Another LinkedIn comment:

George Friesen

Business Practice Leader – Lean Transformations at St. Louis Community College

The opportunity I had in 1986 to see NUMMI as a member of a group doing team-building training was my first view of Lean in action and a real eye-opener. How different NUMMI was from other automobile plants I’d done training in. Happy motivated workers making high quality products. As an admirer of the creativity of Elon Musk, I hope he comes to recognize that motivated, well trained human beings are the foundation upon which manufacturing success absolutely depends.