Yesterday, I saw this headline from the Associated Press:

“Tatsuro Toyoda, former head of Toyota, dies at 88“

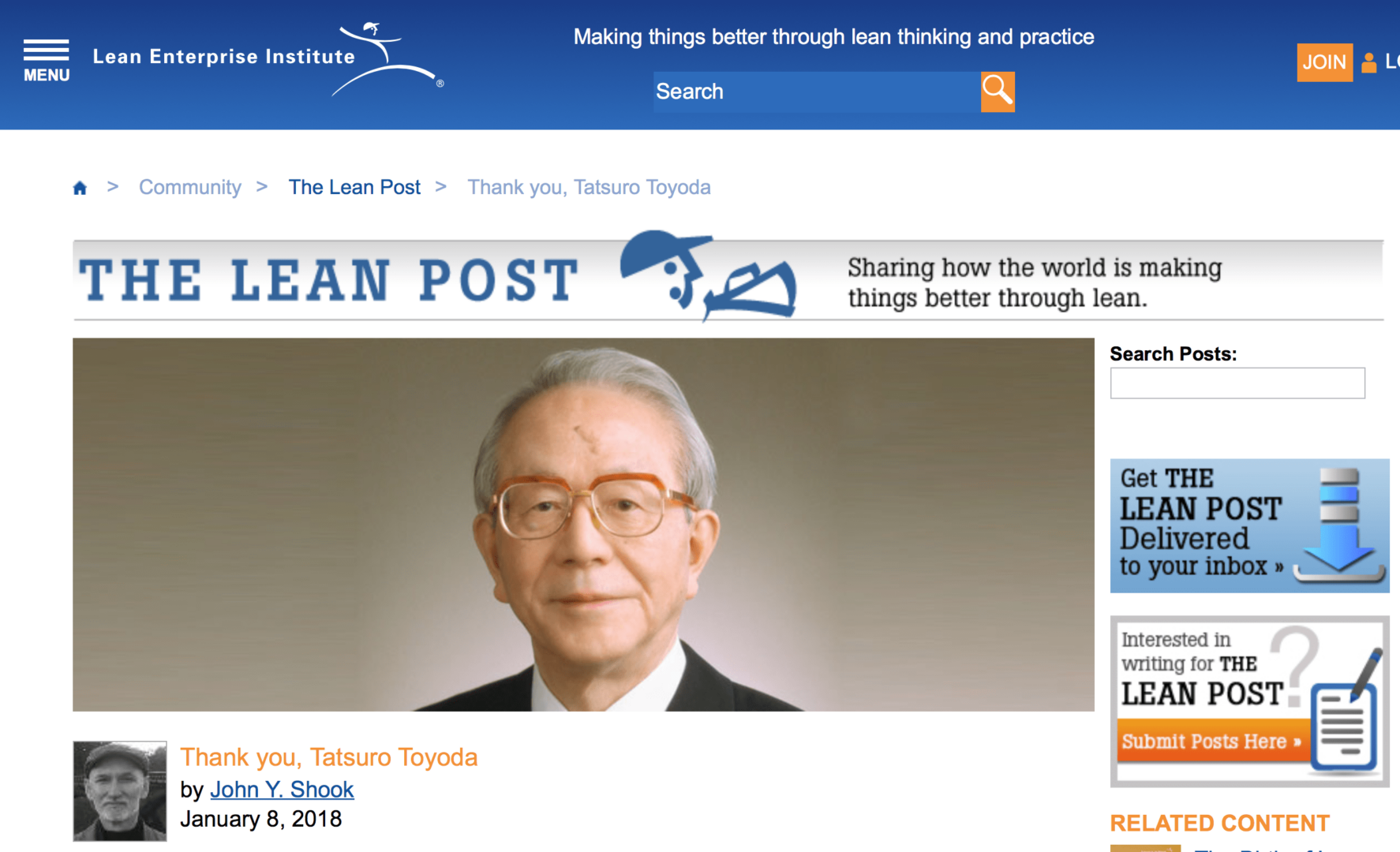

He passed away on December 30, 2017. I offer my condolences to his family, friends, and colleagues.

“Mr. Toyoda, the automaker's seventh president and son of the company's founder, stepped down from the [President] position in 1995, while continuing in other posts, such as adviser, a title he held until his death.”

His Role in Starting and Leading NUMMI

Again from the AP:

“He was instrumental in setting up a California joint venture with U.S. rival General Motors in 1984, called NUMMI, or New United Motor Manufacturing Inc. At that time, it was heralded as a pioneering international collaboration.

Mr. Toyoda served as NUMMI's first president and became known for his efforts to bring Toyota's corporate culture of super-efficiency, teamwork and empowering workers together with American culture, including introducing a new style of labor-management relations.”

I have blogged about NUMMI a lot over the years, having visited there in 2005. I wouldn't necessarily focus on “super efficiency” as the driving goal of TPS or Lean. Toyota's website says the main pillars of TPS are flow and quality at the source. Flow and efficiency are not the exact same thing.

But, yes, Lean and TPS are about teamwork, empowerment, and a new style of labor-management relations. Toyota was successful with their NUMMI joint venture, even with the UAW in place and hiring workers from the old pool of GM-UAW workers. The difference was the management style, as I saw when I was part of the early days of a Lean turnaround at a GM plant in Michigan over 20 years ago.

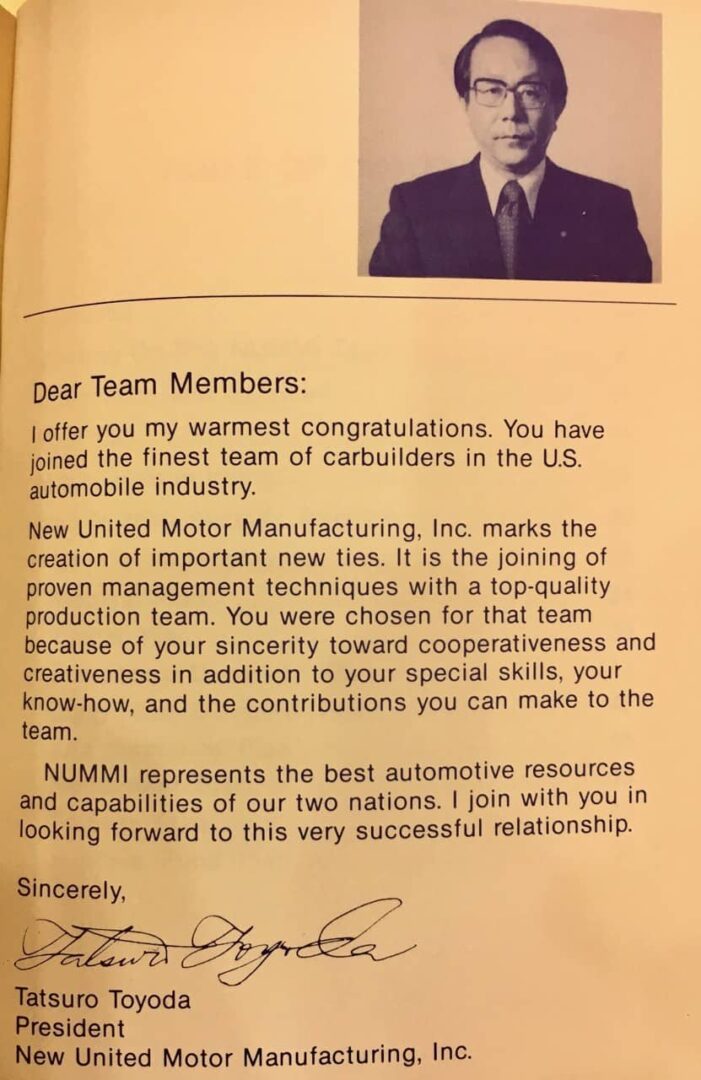

Mr. Toyoda's picture can be seen in the NUMMI employee handbook from the plant's opening, as I shared in this blog post.

The NUMMI success story was, of course, the precursor to Toyota's further entry into North American manufacturing. NUMMI has also inspired many as an example of a Lean turnaround story, there Toyota helped turn a terrible General Motors facility into a successful plant – thanks to the Toyota Production System management approach.

You can hear my podcasts with one of the early NUMMI employees, Steve Bera.

I asked Steve for some reflections and he shared this:

I read of Mr. Toyoda's passing was also saddened to read the announcement.

My personal association with Mr. Toyoda taught me that no matter how many or how few chevrons I had on my sleeve, his respect for his team members (at all levels) was based upon one's commitment to respect, trust and accuracy of information provided to him.

He would sign off on my request for a million dollar expenditure by noting that I had secured the approval of all those affected before I got to him. You didn't have to gain his trust, but you could lose it. As I have said previously, “humility” was the cornerstone of the Toyota team philosophy that Mr. Toyoda helped breed into all of us.

Hope that gives you a bit of insight into my view of Mr. Toyoda.

Thanks, Steve! He sounds like quite the leader and role model.

Reflections from John Shook

Here are thoughts shared by John Shook, who told me in an email, that he knew Mr. Toyoda well from his time at NUMMI and beyond.

John wrote:

“Without NUMMI and its lessons, I doubt whether the Detroit Three would have even survived until the Great Recession when two of the three filed for bankruptcy.”

John writes of meeting Mr. Toyoda:

“Tatsuro was polite, telling me of his time studying under Dr. Deming at NYU, and animated in relating stories of driving across the USA in a rented Chevy as a young man.”

Thanks to John for sharing some of his memories and reflections.

Part of the Toyoda Family

Tatsuro Toyoda was the son of Kiichiro Toyoda, founded the Toyota Motor company in 1937. Again, from the AP:

“He succeeded his brother Shoichiro Toyoda as company president. The current president, Akio Toyoda, is Shoichiro Toyoda's son.”

Illustrating the connection between Toyota and the late, great W. Edwards Deming:

“Mr. Toyoda earned an MBA in 1958 from New York University, where he studied under quality-control expert W. Edwards Deming, who was credited with influencing Japanese manufacturing and helping to develop its reputation for quality.”

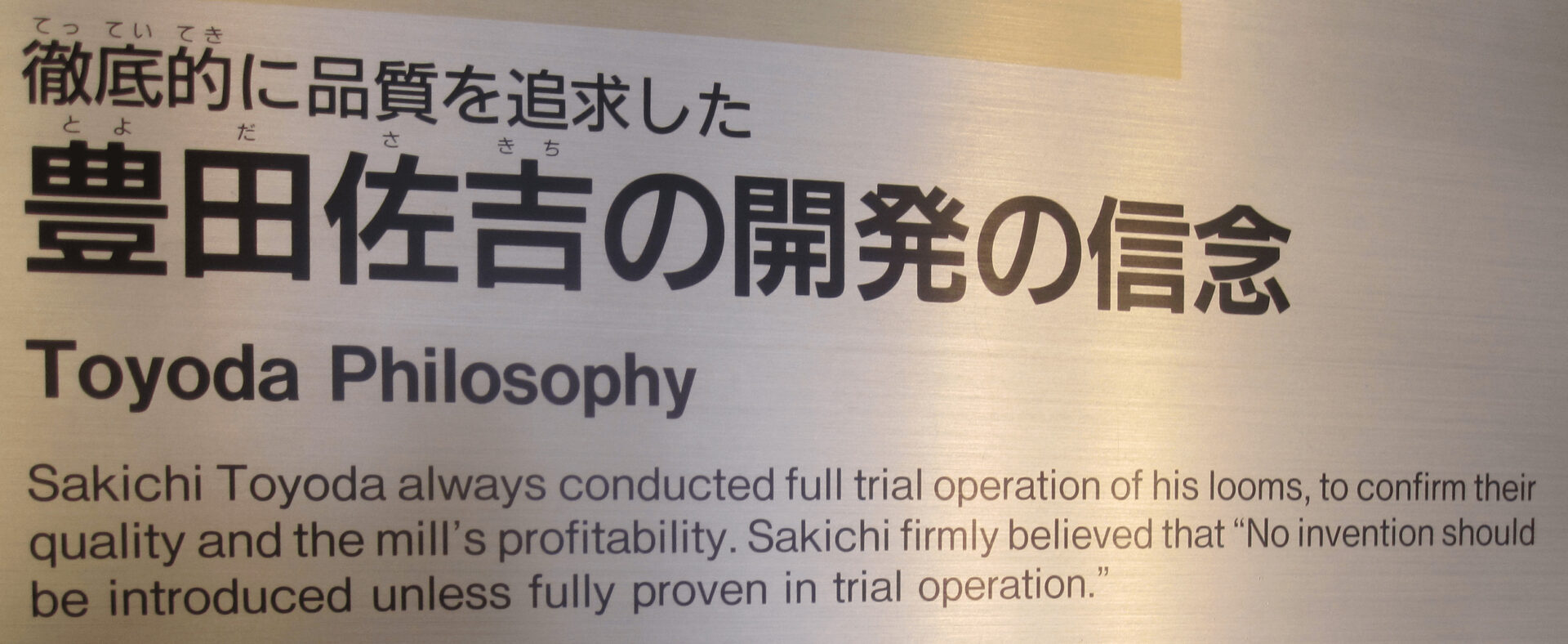

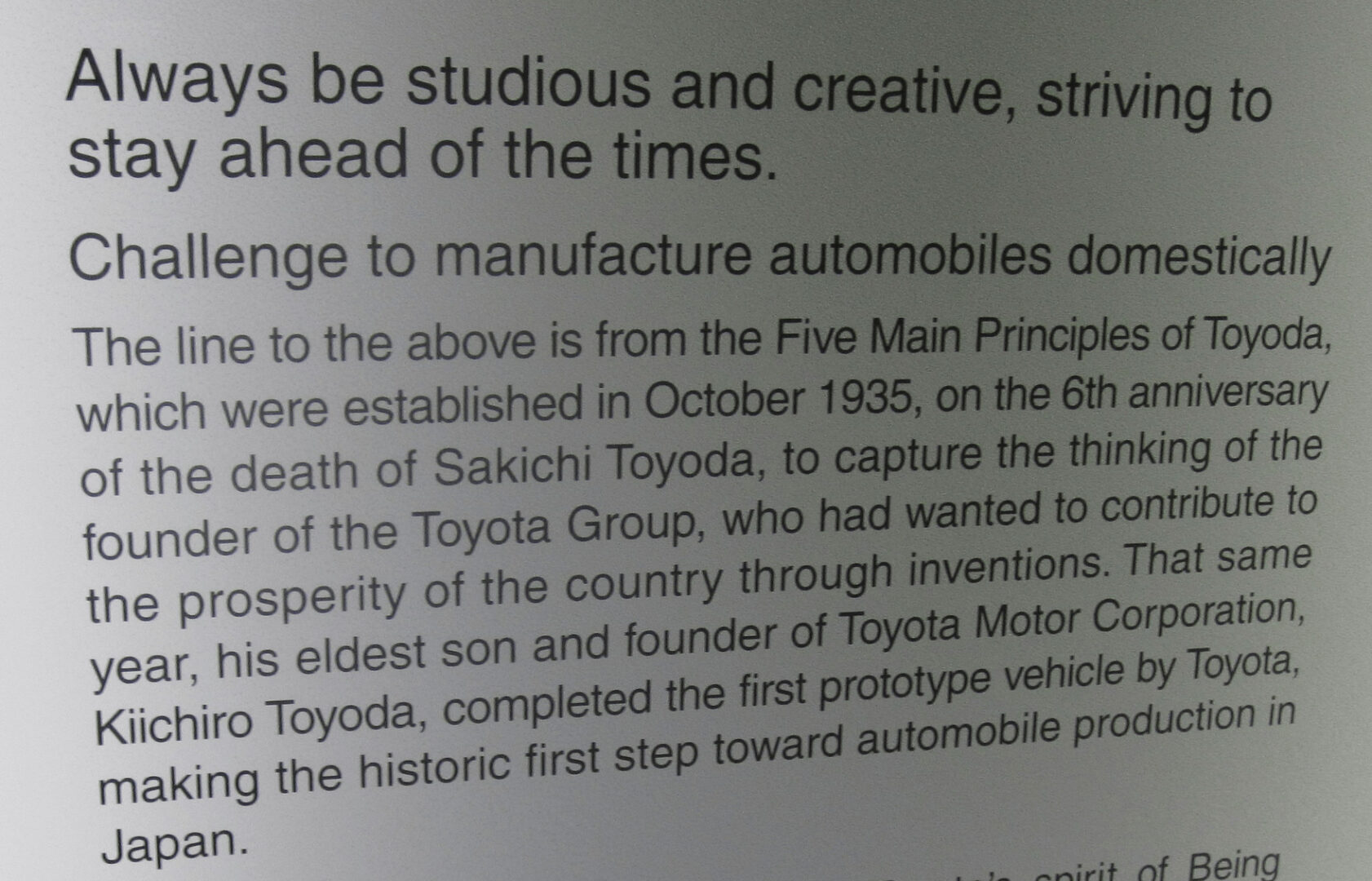

As I prepare to go back to Japan in late February for another Lean healthcare study tour (there's still room if you want to join us), I was flipping through some pictures the other day with quotes from the Toyoda family. Their family has contributed so much.

“No invention should be introduced unless fully proven in trial operation.”

That reminds me of modern-day Lean Startup thinking, with the “Minimum Viable Product” and other Kaizen or continuous improvement approaches that involve a “small test of change.”

“Always be studious and creative, striving to stay ahead of the times.”

Rest in peace, Mr. Toyoda. Thanks for bringing Toyota and TPS to the United States and helping make the entire auto industry (and many industries) better as a result.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.