I recently wrote about my exploration of the collected papers of the late Don Ephlin, a UAW senior leader and a professor of mine at MIT.

I recently wrote about my exploration of the collected papers of the late Don Ephlin, a UAW senior leader and a professor of mine at MIT.

In that first post, I shared a few quotes that were scattered around the original NUMMI Team Member Handbook from 1984, the year that the plant re-opened as the joint venture between GM and Toyota. (Read past posts about NUMMI).

Remember that this used to be a GM plant in Fremont, California. It was re-opened with employees from the GM/UAW pool – and with completely new management (including people like Steve Bera, who I interviewed in a two-part podcast). It was most importantly a new management system that led to NUMMI's success.

You can see the difference in culture and management approach in the handbook.

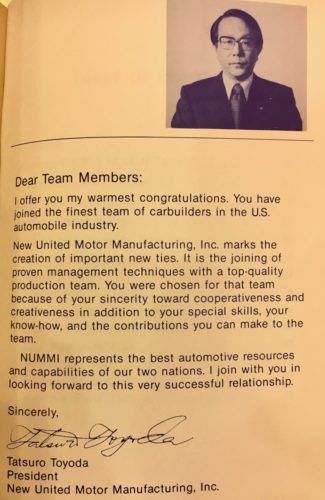

The welcome letter greets the new NUMMI employees and sets the tone (click any photo for a larger view):

When I worked at GM from 1995 to 1997, the default plant culture was that management blamed the workers. The assembly workers, machinists, trades, and other UAW employees were generally looked down upon, if not belittled. That started to change when got a new plant manager, Larry Spiegel, who was one of the original NUMMI managers.

In this letter, Tatsuro Toyota is complementary of the workers, calling them the “finest team” with “sincerity toward cooperativeness and creativeness” among other positive traits. The GM I knew never praised the workers like that.

In this letter, Tatsuro Toyota is complementary of the workers, calling them the “finest team” with “sincerity toward cooperativeness and creativeness” among other positive traits. The GM I knew never praised the workers like that.

Toyoda also highlights how the workers will be effective in combination with “proven management techniques” – basically the Toyota Way, the Toyota Production System, and what's now called “Lean” in many circles.

GM had an “us versus them” mindset, where NUMMI was trying to set the tone for teamwork and cooperation.

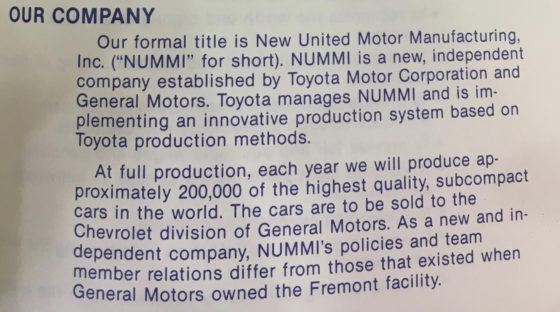

Another early page introduces the concept of NUMMI:

The book establishes that, although it was a joint venture, it was managed by Toyota under the Toyota methods… their “innovative production system.”

It's interesting to me that it says “based on Toyota production methods.” How much was Toyota adapting their Toyota system for an American workforce? I'm guessing that, when they started, they didn't know how much they might have to adapt as part of the NUMMI experiment. This small test of change was their first time with an American workforce. I'm happy to see that even Toyota didn't assume they could just copy-and-paste their system into a new country and plant… that's a lesson that's often shared on this blog: learn from others, but don't copy blindly. You can adopt and adapt Lean or other methods for your setting. As I wrote in 2010:

The handbook also points out that “NUMMI policies and team member relations differ from those that existed when General Motors owned [and ran] the Fremont facility.”

I'm sure it took some time for Toyota and the NUMMI team to build trust with the old GM workforce. A handbook was only a first step. They had to “walk the talk” and practice what they preached. When I was at GM in the mid 1990s, we had documents that talked a good game about teams and quality – but it wasn't the daily reality. So, that bred dissatisfaction and cynicism. NUMMI had to undo a lot of those feelings, I'm sure.

The section on Philosophy is a statement that I'd argue could apply well to any hospital or health system (or other types of organization) today:

The focus is on:

- Teamwork toward a common goal

- Efficiently producing quality at the “lowest possible cost” (putting quality first as opposed to prioritizing cost cutting, as many hospitals do)

- Providing fair wages and benefits as a team

- A team environment that benefits each person (not just the organization)

Does that line up with your current organization, today? If not, where are the gaps between your organization's philosophy? Is there a gap between your organization's stated philosophy and the daily reality?

I love the focus on the employees and creating a great workplace (not just maximizing profit for the organization.

The themes include developing people, dignity, mutual trust and respect, and teamwork.

The goal of the plant is “continuous employment” (a no layoffs pledge stated in other NUMMI/UAW documents) and that comes through continuous productivity improvement.

This improvement would come by encouraging the participation of everybody in improving the work environment. That's Kaizen! But it's interesting to me that they didn't use the word here. I guess they were tailoring this for an American audience by using all English words, right?

The last thing I'll highlight in this post is this:

They talk about fairness and open communication (two things GM struggled with).

Having an “active role in determining how best to do your job and improve the working environment” again sounds like Kaizen.

How do you create a culture of continuous improvement? The same ideas hold true today — breaking down barriers. Working as a team. Suggestions and recommendations being respected and acted on. Helping people do their job better.

What a great document. That's just the first few pages. I'll share more in future posts, including highlights from a document that GM wrote after a few years of NUMMI with lessons learned.

See Part 2 of my posts about this handbook:

Part 2: More From the Original 1984 NUMMI Team Member Handbook: Unions, Teams, Leaders

Again, here's the first post in this series if you missed it:

Coming Soon: A Fresh Look at Some Old GM & NUMMI Documents About Lean, Japan, and More

Click here to read all posts in this series. More to come!

Note: Ephlin's UAW office papers are archived at the Walter P. Reuther Library at Wayne State University in Detroit. Thanks to them for maintaining the collection.

Update: Chris Gagne received permission to post the full PDF on his website. Click here for his blog post that contains a link to the PDF.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Nice post. The “Our Objectives” image clearly articulates an worker-centered approach to introducing TPS, rather than a manager-centered approach. Respect for people from the very start.

Yes, thanks for highlighting / amplifying that point.

I do appreciate it when I see organizations today that are focused on the customer and the employee, not just the benefits they want for the health system or hospital. It’s not really Lean or Kaizen if management is only concerned about cost reduction, of course.

One of my main passions is creating better work environments for people. At GM, most everybody (hourly and salaried) hated coming to work most days. It doesn’t have to be that way. The NUMMI experience (and part of what I saw at a GM plant under a NUMMI-trained GM plant manager) shows that it doesn’t have to be that way.

And by focusing on teamwork and the workers (and a new management system), we can improve safety and quality, my other main passion in healthcare.

Too many healthcare organizations in 2016 are more like 1983 Fremont Plant or the 1995 GM plant I worked at. The problem is not the workers…

One other reflection on reading the entire handbook (and I’ll share more from it), there’s not a single mention of tools like kanban, SMED, 5S, etc.

It’s all about themes like management system, teamwork, employee engagement, continuous improvement, satisfying if not delighting the customer…

How many organizations that say they are “implementing Lean” are totally missing ALL of these elements of TPS, aka “Lean?”

Far too many.

The concept of the “andon cord” and the responsibility to pull it is mentioned, but I don’t think that term was used.

And therein lies the glaring omission in almost all of the early (U.S.-based) research that studied and described TPS. Careful study of available documentation at that time would have revealed some of this critically important information: Mindset and human relations are far more important than the tools (Frank Woollard at Morris Motors recognized this in the 1920s).

Check out this book from 1989 by Ken Wantuck, an APICS dude who had a very good understanding of the people aspects http://www.bobemiliani.com/just-time-america/

Wantuck’s work was almost entirely ignored by all other researchers who studied TPS in the early days. You can buy Ken’s book from amazon. There are about 50 copies available for less that $5. It’s a good addition to one’s library.

Thank you for sharing the details of the handbook in this and future posts. Your comments about how Toyota went about bringing the Toyota management system to NUMMI remind me of comments that Isao Yoshino has made to me about his role in the role in the process. Mr. Yoshino, along with John Shook and others, were tapped in Nagoya to think about how they could teach TPS to an American audience. I imagine that this book is a result of their preparation work. I’ll ask him! In one of my earlier conversations with Mr. Yoshino, he shared that the he and other Toyota leaders “GM managers at the NUMMI plant through an initial three-week training course, which helped shift their mindset. But the real learning only came when the leaders and trainers showed them on the shop floor how to manage, and helped them practice and change their behaviors.” (http://kbjanderson.com/lean-leadership-lessons-and-gemba-visit-to-toyota-city-japan/)

[…] Here’s Part 2 of a post about the original NUMMI Team Member Handbook from 1984 (see Part 1 here). […]

[…] recently came across Mark Graban‘s “Highlights from the Original 1984 NUMMI Team Member Handbook” series. Digging through the archives at Ephlin’s UAW office papers were archived at […]