Today's Post in <50 Words: I write about how Kaizen starts with yourself. I share some examples of “personal Kaizen,” including the way I've streamlined my call scheduling process, for my benefit and for others.

I believe strongly that the first step in creating a culture of continuous improvement is improving something in your own work — taking action instead of just encouraging others to do so.

I had some problems or frustrations related to meeting scheduling back in 2014, so here was my post about the Kaizen improvements that I made then:

Hear Mark read this post (subscribe to the podcast):

Start Kaizen by Looking in the Mirror

One thing you'll learn if you come visit Franciscan St. Francis Health in May is the advice they give their leaders:

“If you want to see Kaizen in your department, start by doing a Kaizen yourself.”

When they say “doing a Kaizen,” they mean following the PDSA process to identify and test a small change related to your work; the smaller, the better. Leaders lead by example… they appreciate what's involved in Kaizen, which allows them to be better coaches to their staff. Leaders there practice what they preach.

Paula Stanfill, their NICU manager, rounds and asks staff if they've identified problems or have ideas. Once, I saw her ask a new nurse if she had any Kaizen ideas. The nurse looked dejected and said, “No, I can't think of anything.”

Paula was so kind and patient in response. “That's OK,” she said, “Let me show you what we mean by Kaizen.”

Paula then explained how she had always been grabbing the wrong key when trying to open her office door. So, she put an orange sticker on the key. Kaizen!

The nurse she was talking to took a breath and smiled, saying, “Oh, I could do something like that.”

Small ideas don't save the world.

But, small ideas start the culture change… leading to more ideas, bigger ideas, and great impact.

See some of Paula's department's Kaizens here.

Practicing What I Preach and Improving

I look for Kaizen opportunities in my own work all the time. I can't help it.

Years ago, I created a checklist that helps me prevent errors in my podcasting process:

And my checklist / process has continued to evolve over time (for example, iWeb is no longer a thing, and I don't publish an AAC format of the podcast anymore).

Joe Swartz and I did “a Kaizen” together when prepping for a workshop:

Improving My Scheduling Process

One thing I do very often is schedule phone calls or web meetings with other people.

Because I'm a “company of one,” I'm not in people's corporate Outlook calendar servers, so they can't see my schedule.

In the past, the scheduling process involved MANY emails back and forth, such as:

- Me: Let's schedule a meeting

- Them: OK, great, when are you free?

- Me: How about March 20 or 21, or April 7?

- Them: Those days are bad… what else?

- Me: How about March 23, I guess I could make time?

- Them: OK, let's do 4 PM.

- Me: What time zone?

- Them: Sorry, 4 PM central

- Me: Ah, I can't move that one appointment… I can be free from 9:30 to noon or 2 to 3. Central.

- Them: OK, let's do 10:30 am… please email my admin

ARGH.

One Kaizen I did years ago was to publish my work calendar publicly through Google Calendars. I sometimes “block” time generically and don't share every detail with the world, but people could “read only” to see when I was free.

So, the process was a bit better:

- Me: Let's schedule a meeting. You can see when I'm free at this link.

- Them: How about March 23 at 4 PM.

- Me: What time zone?

- Them: Sorry, 4 PM central (Pro tip: ALWAYS reference time zone with a time)

- (time delay of a day)

- Me: Wait, something else got booked at that time. Can you do 11 AM?

- Them: OK, please email my admin

That was a little less frustrating in that the other person could SEE when I was available. And, it was relatively “real time.”

It was a problem, though, if two people requested the same time when I was away from my computer (which, believe it or not, happens).

There would be cycles of rework and the process wasn't much better than before.

PDSA:

I Planned (identified a problem and analyzed it), Did (shared my calendar publicly), Studied (hmmm, it could still be better), and Adjusted (let's try something new). That's PDSA.

That's Kaizen.

My New Scheduling Process (as of 2017)

I was introduced to a website and tool called YouCanBook.me (YCBM). There are many competing services, but I like this one. The free version is pretty useful. I liked it so much (“Study”) that I felt guilty NOT paying a few dollars a month for their premium service. This isn't a paid endorsement… I just love the service… and the process I built around it.

Here is the new process:

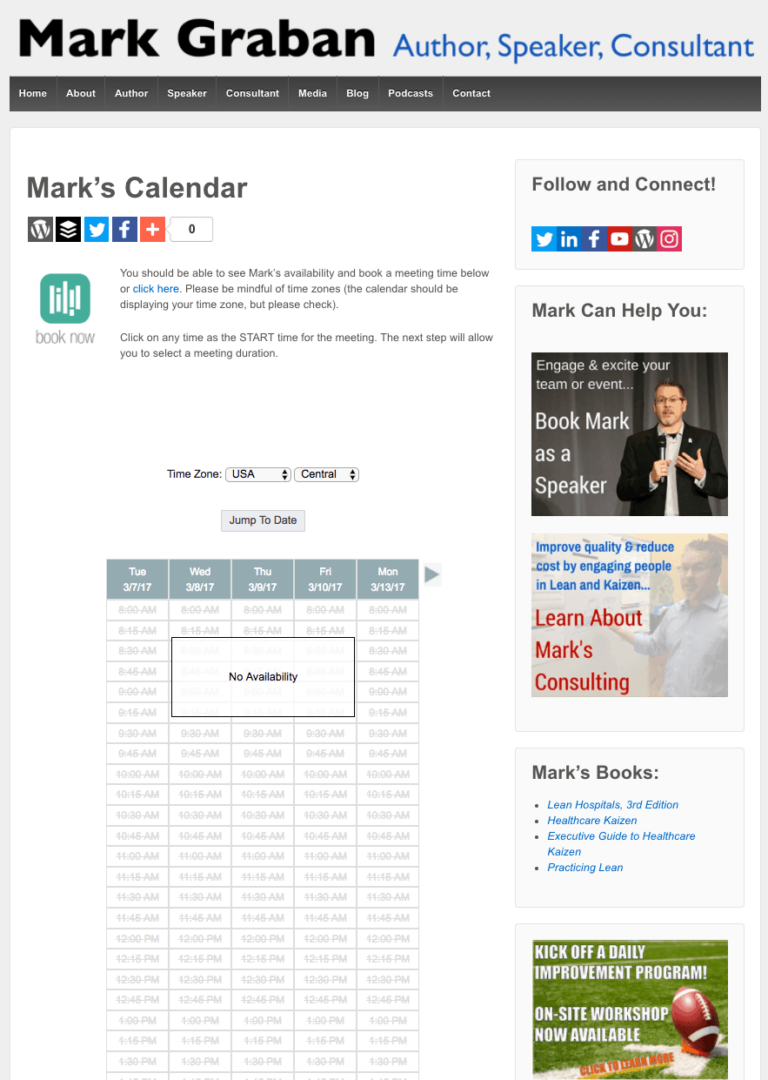

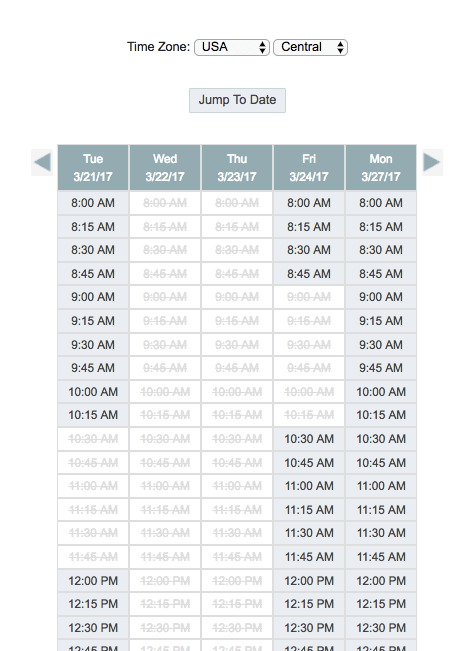

- I mention the ability to find and schedule time through my website at https://www.markgraban.com/cal/

- They see my real-time availability for a meeting and compare it to their calendar.

- They click a few times and choose a day, start time, and duration and click submit

- The event immediately (or close to it) goes into my calendar. This is “read/write” access, not just “read only”

- I get an email notification

It's a far simpler process. It's easier for me. There's less back and forth.

Better yet, my clients (or potential clients or people I'm mentoring) LOVE this new process.

I'd say 75% of the time, somebody comments something to the effect of:

“I really LOVE that scheduling page. How do you do that?”

I hope providing a smoother process and better experience creates a good impression. I want people to realize I respect their time and want to make work easier for them (not just for me). I want people to see that I practice what I preach (or try my best).

If you'd like to schedule time to talk about how I can help your organization as a speaker, trainer, coach, or consultant, feel free to schedule some time with me (or use this contact form). If you have questions about Lean or Kaizen or would like to compare notes on what you're working on or whatever, feel free to use this process.

Here's how that form looks for next week (I'll be in Europe teaching some workshops and attending the Lean Healthcare Transformation Summit there).

But there's time in the future:

How can I help or provide value to you? Is there something that we can talk about working together on?

What Kaizen can you implement today in your own work?

Some Small Improvements in 2019:

It's a never-ending journey, so I made some other small tweaks:

Additional Improvements in 2020

As life and work became VERY online in 2020, I made some other improvements:

New Process / Technology for 2023

Calendly.com seems to be the winner in this meeting-scheduling space. I've started using it — or at least I'm doing some small tests of change for:

- Meeting scheduling

- Podcast episode scheduling

There are a few advantages that I see:

- The ability to limit a certain meeting type (like a podcast recording) to just ONE per day (a feature that YouCanBook.me says is coming soon)

- The interface is a little simpler, I think

There's one disadvantage, or thing I haven't figured out yet:

- It seems that all meetings are fixed lengths, so I can offer a 25- or 50-minute meeting and the scheduler cannot choose the length of their meeting as YCMB allows (but this is also fewer clicks to schedule)

I'll keep experimenting. Both services are relatively inexpensive, so I'm in no rush to cancel YCBE right away…

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

That reminds me of a study done at Harvard a few years ago where they analyzed the downstream impact of an improvement that resulted in a more efficient process for ordering ultrasounds in an ED. The most interesting outcome was that although the improvement reduced the amount of time an ultrasound patient spent in the ED, it also resulted in a 70% higher likelihood that a patient with abdominal pain would receive an ultrasound. Since it was so much easier to order, docs began ordering them more even where it wasn’t clinically appropriate (as measured by clinical quality outcomes). The increased volume actually increased radiology wait times for both ultrasound patients and patients undergoing other imaging procedures. So the “efficiency” improvement actually resulted in a reduction of overall clinical quality.

I wouldn’t think you’re seeing the same thing with more meetings/appts as a result of your process change, but this is one of the things that makes healthcare so complex (and fun). It’s also why I’m so wary when I hear about hyper-localized lean results. Hospital processes are so interconnected and interdependent, it’s hard to make a change that doesn’t have a significant downstream impact. It’s so easy to shift waste around in the process without realizing it. It’s easy to fix the process. Much more difficult to fix the system.

Thanks for the comment, as always, Robert. That’s a great story and example of the need to look at systems. That’s part of the PDSA process. We might think we “fixed” a problem locally, but we need to look and make sure there are no intended consequences that were created.

The next problem to solve in your scenario would then be helping doctors know to not over order tests?

One problem often leads to another. I’m guessing we’d agree that we wouldn’t say that the original ultrasound work shouldn’t have been done? Too many negatives, sorry.

It is more difficult to fix the system, but that should be our aim… even if we take a wandering path to get there.

Is it better to anticipate system effects up front? Sure. But, easier said than done? I think forming cross functional teams across department boundaries helps avoid sub-optimization.

My new process hasn’t led to more meetings. Although this blog post might lead to that. But, I’m sure they will be productive and interesting.

i like this post and just to wish you an excellent summit in Europe, enjoy!

I saw an ad for this service, which seems (at first glance) to be technology that automates the back-and-forth scheduling waste, instead of trying to eliminate it:

https://x.ai/