Last week at the Lean Healthcare Transformation Summit, I really enjoyed the presentation by Jamie Bonini, General Manager of the Toyota Production System Support Center (TSSC). Jamie started his career at Chrysler (where he knew Jamie Flinchbaugh, a good friend of this blog), and both Jamies, like me, are graduates of the MIT Leaders for Global Operations program.

Jamie shared great insights on what we might call “Lean culture” as Toyota aims for and others have emulated.

Jamie described Toyota's organizational culture as an integrated system, consisting of:

Basic philosophy

- Customer first (patient first in healthcare)

- People are the most valuable resource

- Kaizen (continuous improvement)

- Focus on the workplace (shopfloor focus, gemba)

Managerial approach

Jamie said the key managerial role is to develop people to surface problems and to solve problems (to better serve the customer). He emphasized this many times. Managers and leaders are responsible for helping create a culture where people can surface and solve problems.

Technical tools

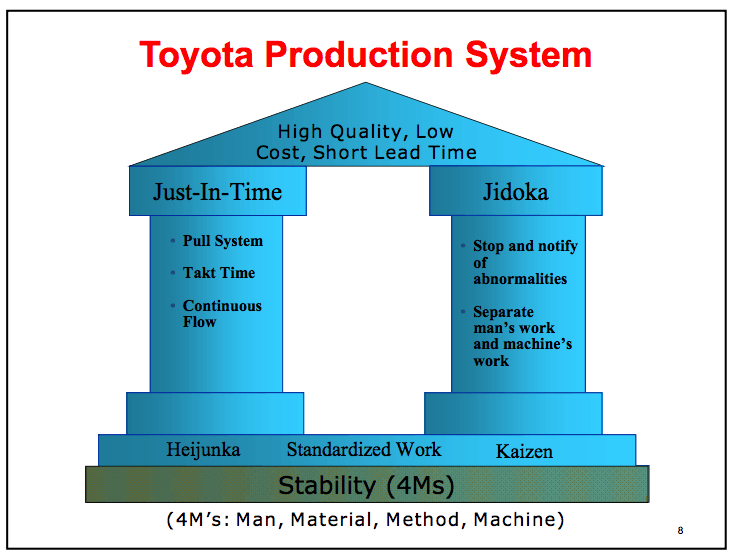

These are the methods like kanban, just-in-time production, etc. As Jim Womack said in his keynote, these tools are “necessary, but not sufficient” because they have to be combined with the philosophy and managerial practices. The classic “TPS house” illustration covers these practices (or see Jamie's diagram, below):

The diagram presents the familiar “house” model of the Toyota Production System. At the roofline is Toyota's aim: deliver high quality at low cost with short lead times. That goal is supported by two major pillars.

The first, Just-In-Time, represents designing work so that materials and information flow smoothly according to customer demand–using a pull system, takt time, and continuous flow.

The second pillar, Jidoka, reflects Toyota's expectation that problems are seen and addressed immediately. When an abnormal condition occurs, the process should stop, the cause should be understood, and human work should be kept distinct from machine work so issues don't stay hidden.

These pillars stand on a base of Heijunka (leveling work), Standardized Work (defining the best-known method), and Kaizen (improving that method over time). Beneath everything is stability in the “4Ms”–man, material, method, and machine–because without basic consistency in these inputs, none of the higher-level practices can function reliably.

More on the managerial approach

The ideal is to be notified of any abnormality immediately and to solve problems as they occur (while the situation is still fresh).

Jamie referenced back to Dr. John Toussaint‘s keynote, with all of the things that went wrong during his mother-in-law's healthcare, saying,

“A problem solver would have arrived immediately to solve the root cause and prevent it from happening again.”

Unfortunately, that's still not the culture in healthcare, generally.

That's the power of Lean principles. It's not about copying tools, it's about adopting the culture and philosophy. That's what makes the tools useful, when oriented in the direction of the customer.

For example, I'm not sure how saying “no sweaters on the back of your chair” (in the Kyocera “Lean office” initiative) helps the customer at all! That's why I called that “L.A.M.E.” and not Lean. That's why we need to be customer-driven (solving problems that matter) rather than being tool-driven.

Four roles of a leader

Jamie talked about the four roles that each leader must play in a Lean transformation:

- Show passionate commitment for improvement and TPS

- Learn TPS principles, well enough to teach them to others (the basic principles and the details)

- Build an organizational culture that surfaces and solves problems

- Be active in the gemba (go and see… “genchi gembutsu”)

Taken together, the TPS house reminds us that Toyota's results don't come from isolated tools or heroic problem solvers. They come from an interconnected system of philosophy, leadership behaviors, technical methods, and stable processes that make it easy for people to see problems and improve every day. That was the essence of Jamie Bonini's message: when organizations focus on developing people and strengthening the underlying system, the tools become far more powerful–and the culture becomes capable of sustaining real improvement.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.

Engaging with Jamie is always a learning experience. I hope everyone at the conference appreciated the experience. Last time we chatted at an airport (both coming off long flights and probably looking and certainly feeling ragged) we got into a deep conversation about how to fix the university system in the US.

Fixing the university system… you might be interested in Bob Emiliani’s new book and blog on this (“The Lean Professor”). He’s also written another book about Lean in the college / university setting.

http://www.bobemiliani.com/the-lean-professor/

Great post. I am looking back 5 or 6 years and as much as this rings true now I am not sure it would have resonated then. I guess the good news is we are figuring this out and there are bona fide examples in healthcare that can inspire us. Maybe the bad news is it is still very hard and I am not sure there are that many leaders that are capable of moving their organizations down the right path.

Comments are closed.