Joining me for Episode #344 is David Reid, a mechanical engineer whose career has taken him from improvement work at Michelin Tire, to being a pastor, to now helping the Chick-fil-A restaurant chain improve through Lean and Kaizen practices and mindsets.

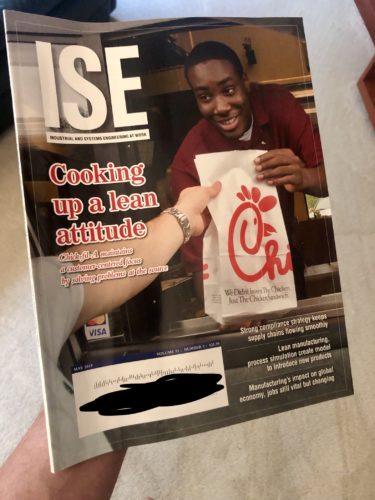

I was really excited to see the cover story that was in the May 2019 issue of ISE Magazine (Industrial & Systems Engineering). The headline inside reads, “From lean modules to a lean mindset — Chick-fil-A's success shows how leveraging your greatest asset speeds up cultural change.”

In this episode, I get to ask David about some of the drivers for Lean at Chick-fil-A, which is already a high-growth company with many happy customers and employees.

How do they influence the owner/operators of stores to embrace Lean and to engage every employee in continuous improvement? Why did they learn that a top-down engineering-driven model couldn't possibly drive enough improvement? How does a Facebook page enter the equation for employees (and note that using Facebook was an employee idea) instead of “building an app.”

There are many great “nuggets” of wisdom here from David, pun absolutely intended. I hope you enjoy the episode!

Streaming Player:

For a link to this episode, refer people to www.leanblog.org/344.

For earlier episodes of my podcast, visit the main Podcast page, which includes information on how to subscribe via RSS, through Android apps, or via Apple Podcasts. You can also subscribe and listen via Stitcher or Spotify.

New! Subscribe and listen with Spotify:

Questions, Topics, and Links:

- David's LinkedIn page

- IISE article: “From lean modules to a lean mindset — Chick-fil-A's success shows how leveraging your greatest asset speeds up cultural change” — IISE members only

- Before we talk about Lean at Chick-fil-A, can you first introduce yourself and your career as an engineer and a Lean practitioner? Where did you get started?

- How did you end up at Chick-fil-A?

- What's the need or opportunity for Lean at CFA?

- African proverb: “Every morning in Africa, a gazelle wakes up, it knows it must outrun the fastest lion or it will be killed. Every morning in Africa, a lion wakes up. It knows it must run faster than the slowest gazelle, or it will starve. It doesn't matter whether you're the lion or a gazelle-when the sun comes up, you'd better be running.”

- Why is it important to engage EVERY employee as a lean thinker and practitioner? Can you talk about that evolution from a top-down, engineer-driven approach?

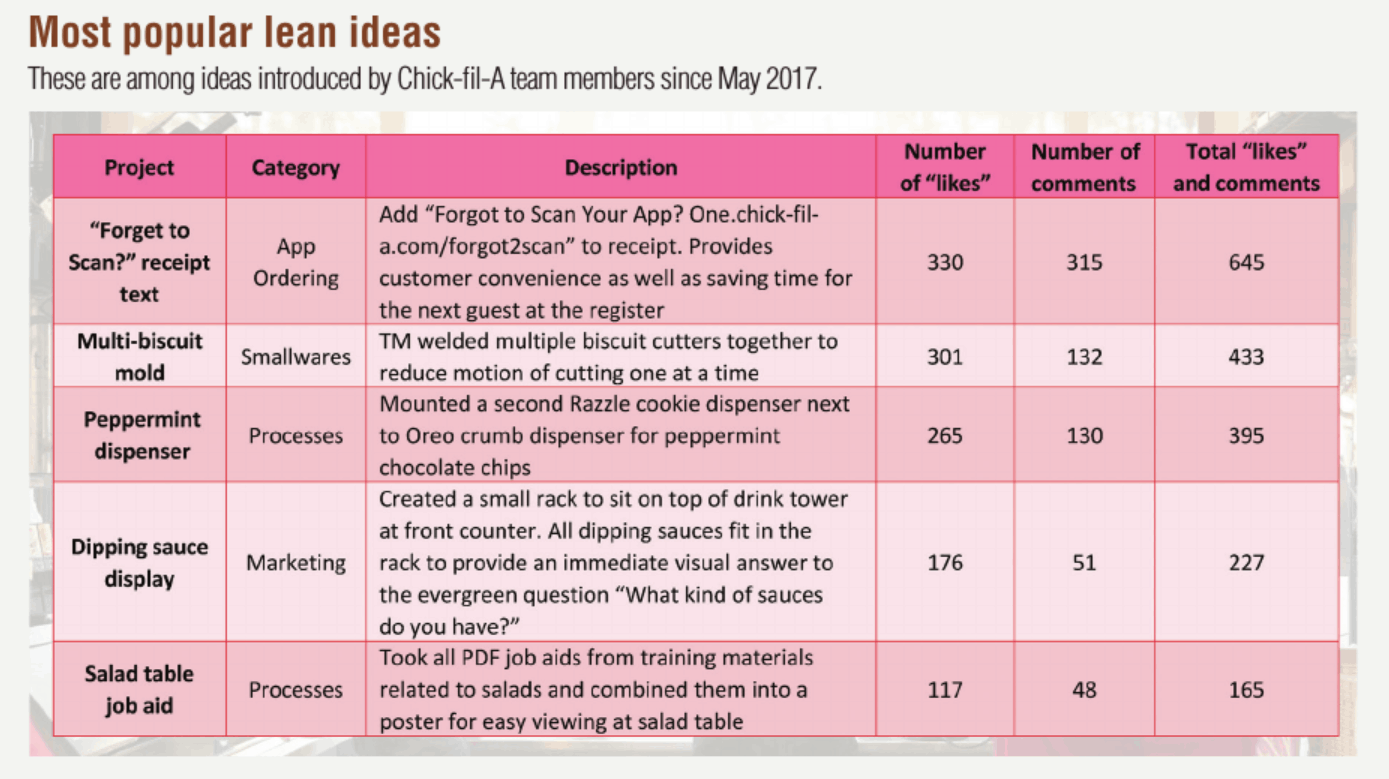

- Examples of employee-driven improvements?

- “Forgot to scan?” message on receipts

- Biscuit roller cutter

- Sauce display for customers

- How can you influence the owner/operators to utilize Lean and to engage people? Pull?

- Why is it important to have “sandbox boundaries” and what are those? What would be out of bounds? What happens if there's an idea that can't be implemented for some reason?

- “I'd much rather have to restrain mustangs than to kick mules” ?

- I know the drive-throughs are fast… 300 cars per hour PER LANE? That's a takt time of 12 seconds… How? :-)

- How do you spread and share ideas across so many locations??

- Lean Facebook site

- Why is it important to celebrate wins?

From the IISE article:

Thanks for listening!

Transcript:

Announcer (42s):

Welcome to the Lean Blog podcast. Visit our website www.leanblog.org. Now, here's your host, Mark Graban.

Mark Graban (54s):

Hi, this is Mark Graban. Welcome to episode 344 of the podcast. It's July 2nd, 2019. Joining me today is David B. Reid. He's a mechanical engineer whose career has taken him from doing improvement work at Michelin Tire to being a pastor for over a decade. And now he's helping lead the Chick-fil-A restaurant chain, improve through lean and kaizen practices and mindsets. I was really excited to see the cover story that was in, or was on the cover of the May, 2019 issue of ISE Magazine. That's the magazine of the Institute of Industrial and Systems Engineers.

Mark Graban (1m 34s):

The headline inside read from Lean modules to a Lean Mindset, Chick-fil-A's success shows how leveraging your greatest assets speeds up cultural change. And of course, that greatest asset is their employees and their team members. They have more than 2000 stores, and in the episode, David describes them as each being a little food manufacturing facility. Each one is about a $6 million manufacturing plant. So today I get to ask David about some of the drivers. What are some of the reasons why Leann is, is needed or why lean is helpful at Chick-fil-A? I mean, it's already a high growth company with many happy customers and employees.

Mark Graban (2m 14s):

How do they influence the owner operators of the stores to embrace lean and to then engage every employee in continuous improvement? Why did they learn that a top-down engineering driven model couldn't possibly drive enough improvement? How does a Facebook page enter the equation for employees And note that that using Facebook was in and of itself an employee idea. Why'd they u Why do they use a Facebook page instead of building an app or buying an app? There are many great nuggets of wisdom in here from David that pun is absolutely intended, and it's the only Chick-fil-A related pun I could think of. So maybe you can think of your own.

Mark Graban (2m 55s):

I hope that doesn't distract you from the episode. I think you'll really enjoy it. If you want to post a comment or see a link to different things we mentioned, you can go to leanblog.org/344. Again, we are joined today by David Reid. David, thank you for joining us. How are you,

David Reid (3m 15s):

Mark? Thanks for having me. I'm really glad to be here doing well today.

Mark Graban (3m 19s):

Well, good. I I loved your article and you know, before we talk about lean at Chick-fil-A and, and some of the really interesting impactful things that, that are happening there, you always like to ask, you know, you're, you're my guest. If you can introduce yourself, talk a little bit about your career and, and lean practitioner. Everyone's got an interesting story and a path to, to all of this. What's

David Reid (3m 42s):

Yours? Yeah, so actually I'm a mechanical engineer from Georgia Tech from a long time ago, and my senior design project was really interesting. So this is thermo principles and all those kinds of things, but my prof would put us in group of, of threes and fours and pose a money saving problem to us for, it happened to be a big hotel in Atlanta, the Western Peachtree Plaza. And he would couch it all in engineering terms like, Hey, on the coldest day of the year, what, how should the Peachtree Plaza heat the building? And then he would lecture for about two weeks on all the different, you know, physical principles that were involved in that.

David Reid (4m 27s):

We would look at utility rates, all those things. And then we would go away and with all these resources, we would write a 10 page paper on what's the most economical way to, to heat the building. And then the, the really interesting thing was he would read all the papers, have about 10 papers from a class of 40 students, pick the best one, you know, give that group, group an A, and then he would go sell that solution to the Western Peachtree Plaza. And so I, I really loved that idea of let's take engineering principles and use them to solve real world business problems.

David Reid (5m 7s):

And when I interviewed for my first job out after college, I interviewed with Michelin Tire Company and I was kind of passionate about that example and, and what we had done to, to really save money. And Michelin said, well, that's what industrial engineers at Michelin do. And I decided that's what I wanted to do. And so went to work for Michelin, they trained me as industrial engineer. I worked there for five years, really tightening up standards, learning about systems, learning about process, and loved everything about it. Really didn't call it lean at that point.

David Reid (5m 48s):

We talked a lot about just in time production, but it was actually later. So, so just a side note, I, I left Michelin and went to seminary and then pastored a church for 10 years. But when I went back into engineering, I kept hearing everybody talking about lean, and I'm like, what in the world has changed that I don't even know about? And I got to kinda taken some refresher courses and I realized a lot of it was the same industrial engineering principles and certainly recognize that Toyota had done a great job of applying principles to reduce waste and satisfy the customer in such a elegant way that touched every part of the process.

David Reid (6m 32s):

It touched how, you know, people approach problems. And from that point on, it was just sold on it and have been a student of lean and read everything I can get my hands on. So that's, that's kind of how I got here. And you know, at this point, I, I conbon things we buy at home for groceries, I fives everything so I can fi find my keys and, and pretty much my first, you know, thought of when I come up with any kind of problem is, you know, what's the lean approach to fixing this?

Mark Graban (7m 3s):

Yeah. And so how did you, how did you end up at Chick-fil-A?

David Reid (7m 8s):

Yeah, so I told you I was a pastor for 10 years, and then after 10 years of church planting, my, my family needed a break and I needed a break. And I was looking to come back in engineering and actually got a headhunter call looking for a Michelin industrial engineer to work at Chick-fil-A. And the story there is my boss was a Michelin i e 25 years ago. I was a Michelin i e 15 years ago. And he just liked the way they approached the world, a very systematic approach to studying all the posts in the system coming up with a continuous improvement plan for every post.

David Reid (7m 50s):

And, and so, you know, no matter what, what you're talking about within the factory, you've got a plan for, you know, when is it gonna become a bottleneck, when you know, when does it need better quality, those kinds of things. And so he was looking for somebody like that. My first thought about Chick-fil-A was they, they, the headhunter PR said, you know, they, one recent thing they're doing is, is analyzing their oven capacity, and I love capacity modeling, but for some reason, oven capacity just didn't sound sexy. And when I told my wife, she said, well, what's so sexy about tires and concrete, two other industries I've been in? Yeah.

David Reid (8m 29s):

And the the neat thing is as I, as I began to work with Chick-fil-A, I found out it's really 2,006 million manufacturing plants that each have different product mixes. They make a perishable product with a variable demand. So you can't just, you know, I, I always joke to my engineers when I made tires, you could make a thousand tires an hour at two o'clock in the morning, chicken sandwiches. You, you can only make a lot of 'em between 11 and one. So really, it, it does have an amazing amount of, of lean applications in, in quick service food industry.

Mark Graban (9m 14s):

Yeah. And so when we were talking about oven capacity, does each location, where, where, where are the ovens? They're, they're not baking their own buns or products their at store, are

David Reid (9m 24s):

They? Great, great question. Not buns, but biscuits. So for breakfasts, we, we actually hand roll our dough and, and make handmade fresh biscuits every day.

Mark Graban (9m 37s):

We're, we're the, the listeners wouldn't know this, but we're recording this during breakfast hours, so I should have been, I should have had biscuits on the brain.

David Reid (9m 45s):

That's right. That's right. And, and cookies, bacon and also macaroni and cheese, which is just in the process of rolling out, probably not in the stores yet. Those, those are the four things that we cook in the oven.

Mark Graban (9m 59s):

Oh, okay. So, so I'm really curious, you know, chick-fil-A has been, oh, oh, I think, you know, by all measures, a really successful business, the, I think of the, the Chick-Fil-A experience, the, the product is delicious, the service is speedy, but yet also courteous, like exceedingly courteous, good customer service. Like what, what, what's the ca what's the, the rationale or the need or the opportunity for lean, I say this half tongue in cheek, like, it doesn't seem like Chick-fil-A needs to improve much, but there's always room, there's always room for improvement. But what's, what's the compelling need for Chick-fil-A leaders?

David Reid (10m 40s):

Yeah, mark, thank you first of all for the kind comments, and it's really our operators and team members all around the country that, that give us that incredible reputation. So thank you for that. Here, here's the best way I can think of it. You may have heard this African proverb. Every day in Africa, a lion wake an a gazelle wakes up knowing that he has to outrun the fastest lion, or he's gonna be eating every day in Africa, a lion wakes up knowing he's got to outrun the slowest gazelle or he's gonna starve.

David Reid (11m 20s):

And so the moral of the story is, no matter whether you're a lion or a gazelle, when the sun comes up, you better be running. And I think for Chick-fil-a w we have had an amazing growth really over the last five years. We've doubled from five and a half billion to 10.6 billion in sales from, from 2014 to 2018. And there's, we're, we're really kinda experiencing Jim Collins' flywheel effect that, that there's been a lot of people pushing on the exact right things for a long, long time. And, and it's just kind of blown up on us in the last several years. But we wanna stay there.

David Reid (11m 60s):

We want to, our goal is to satisfy our customers to second mile service is one of our core values. So we want to actually not just be, you know, a place where you get a, a decent sandwich, but we wanna be the most food safe place in America that provides the fastest service that, you know, meets you where you are. And so with all these dreams we have of how to serve the customer in the best possible way that meets their needs, there's lots of challenges that need to be solved as our supply chain grows, as we, you know, the, the biggest thing with growth is we run the risk of slowing down our service because there's so many people ahead of you who want Chick-fil-A.

David Reid (12m 44s):

And so that's, that's kind of our mantra right now is how do we keep providing convenience and speed, even as we're doing bigger volumes.

Mark Graban (12m 55s):

And so one, one of the things that you mentioned in the IISE article talking about, you know, the drive-throughs and, and during peak times, you know, there, there are some things done you, you can see as a customer to help speed up the flow. And, and, and, and, and there was something in the article about 300 cars per hour. Is that, is that goal, or is, is that per lane or there are some Chick-fil-A that have two lanes for drive-through? I was wondering if you could talk a little bit about some of the, some of that challenge and, and, and, and how the drive-through lanes are improved in different ways.

David Reid (13m 32s):

Yeah, that, that's a great question. And you, if you think about it, drive through is, is a manufacturing process. There's, there's, you know, if you think about it, we, we actually draw maps that shows, you know, first of all, a customer is hungry and then they decide that they want to eat with us. Then they get in our line, then they decide what particular things they want on the menu. Then they have to communicate to that, that to us in an order. Then there's a transaction exchange that happens where they pay for their order, we repeat back to them, you know, a quality step of, of, Hey, this is what you ordered, we got it right, that kicks off manufacturing process in the kitchen to cook the food that you want.

David Reid (14m 20s):

And then there's the delivery and handoff. So you've got this whole process going on and we actually got the, the marrying up of the food and the marrying up of the order taking, all meeting together at the window. And so if you want to decrease that cycle time, what you have to do is start looking at all of those steps as not one serial thing that goes on, but as multiple steps that you could potentially do in parallel. And so if you think about the original drive-through was just, you came up to a window, you ordered, and then you got your food at that same window.

David Reid (15m 2s):

I don't know, back in the 70s maybe restaurants started having a order box up ahead and that lets you take the order and start working on the food before the, you know, before the person gets to the front. We've actually just taken that concept and, and pushed it out as far as we can. So we're doing things now like walking up the lane with an iPad and taking your order way before you get to the window. And what that allows us to do is it allows us start making your food quicker and we can take your payment. And that doesn't even happen at the window anymore. We've started designing our drive-throughs with an exit lane so that you're not trapped, say you just need a number one, but the car in front of you's got four different orders.

David Reid (15m 51s):

Well if, if we can walk down upstream and give you your order, then you can pull out and we actually, theoretically you're getting zero time on that car at the window because we gave you your order before you even got to the window. So there's things like that that we do. 300 is kind of our theoretical maximum right now. First thing you have to do is have unlimited demand. And there are a lot of restaurants, particularly in Texas that do just have constant cars. And very often we will, we will be delivering orders up to four cars back from the window so that as soon as your food's ready, you get to go ahead and leave and never even have to make it to the window.

Mark Graban (16m 38s):

And so part of that is, is design of making sure that there's, let's say, to the right of your vehicle, there's no curb that prevents you from, from pulling out, is

David Reid (16m 46s):

That right? Exactly, exactly. And it also, you know, if we're gonna have team members walking up and down the aisle delivering to cars, we, we actually build a safety lane where, you know, foot traffic can go for the team members to walk up and down so that, you know, cars aren't getting close to their feet in hot and cold places. We have canopies that provide shade and air conditioning and even heaters so that team members can, can work outside and, and still be comfortable. We're experimenting. We've got about three restaurants now that actually have a door at the drive-through window. And so you can actually walk up and down, you know, walk right outside the restaurant and, and go up and down.

David Reid (17m 31s):

The one thing we try not to do is to push you ahead and say, wait, if you've ever been to any fast food restaurant and they tell you to pull ahead, that generally means they've crashed and you're the one holding them up and we'll, we'll help you after we get everything back under control. And that's not a good feeling as a customer.

Mark Graban (17m 49s):

Yeah, I've seen some drive-through lanes, we'll have like two parking spots with signs, like it's almost an expected designed in part of the process at

David Reid (17m 59s):

That point. That's right, that's right.

Mark Graban (18m 2s):

So 1, 1, 1 question, I'm just curious about the production process. What's the mix of how much is assembled to order versus how much is cooked to order Yes, in terms of the chicken and the different components that go into sandwiches, for example?

David Reid (18m 21s):

Yeah, that's a great question. So our breaded entrees, so that's your filets, nuggets, strips, those things have a 20 minute hold time. And so we cook them in batches of, at, at busy times up to 24, it can go into one batch of a fryer. And then we actually have a COBAN system that if you run out of chicken, an empty pan goes back to the breader and that is his signal to bread more chicken. And you already have a reserve pan that's, that's less than 20 minutes.

David Reid (19m 2s):

And then basically if we're in high demand, those pans rotate faster and, and amps up our production. And if we're in a period of low demand in the afternoon, then those plans rotate slower and that throttles down our production. So, so we use a combine system, but our, our chicken has a whole time of 20 minutes, and so you are pulling when, but we don't make a sandwich until it's ordered, so, so we don't toast ahead. So once an order comes in, the bun's toasted, so it's always freshly toasted, you put the pickles on it, you put the chicken on it, and you put it in a foil bag and pass it out. And so our goal is to, to really make sandwiches to order during busy times.

David Reid (19m 46s):

We have certain allowable amounts that you can go ahead and put in the chute just to ramp up for a busy time. But we really try to limit that so that customers are getting hot, fresh product.

Mark Graban (19m 57s):

Yeah, yeah. And, and there's only, I mean that, that allows for customization or remember in business school operation strategy they talk about, they call postponement strategies where there, there are certain components that are common, but then kind of delaying the final customization, the final assembly is close to the customer helps deliver speed and variety. Right,

David Reid (20m 23s):

Exactly. And you know, so any of our deluxe sandwiches which have lettuce tease in tomato on it, those, those, you know, we don't like to put those on the chicken until right when the customer's ready for it. All of our grilled chicken is made to order our salads, we produce bases, but then we put the toppings on them right at the last minute when, when a customer orders 'em. So, so we try to do a balance between being fast but also maintaining freshness.

Mark Graban (20m 54s):

Yeah. So, you know, whether it's drive-through lanes or other improvements, let's say inside the stores and, and locations, some of those things sound like engineering projects. And in the article you talk about kind of the balance or the transition from engineer driven projects to engaging every employee as a lean thinker, a practitioner, an improvement person. Can, can you kinda share a little bit about that, that balance or that evolution and what you and Chick-fil-A have learned?

David Reid (21m 32s):

Yeah, so this, this has been a, a breakthrough for us. So, so I think most of us came from a background where you, you know, you go to engineering school for four years, you learn the ropes for a couple of years on your job, and then you actually now are qualified to begin to come up with improvements for your organization. And that's a really expensive way. So you've got highly paid engineers and you know, we used to have like six IES for one tire plant. Now I've got eight IES for 10 billion worth of sales, over 2200 manufacturing locations.

David Reid (22m 16s):

So you only get to deploy those expensive resources on very top, you know, problems that, that nobody else knows how to solve. Well what that leaves is a ton of problems that anybody who's got a lean mindset could absolutely solve. And so one is, is it would cost too much to, to have, you know, another a hundred engineers working on everything that could be worked on. Certainly that's not scalable that, you know, hey, every time we had a restaurant, we need to add an engineer. And then the other thing is, it is too slow. So right now we do about 40 projects.

David Reid (22m 56s):

We, we have about 40 projects on our plate and that I mentioned the IE part. We've got about two dozen engineers that that prototype and validate and launch things out. So we're working on 40 projects, but there's way more than 40 opportunities in the restaurant. So what we did is we said, Hey, one of the eight waste is your team members. What, what creativity and skills do they have working in the giba every day, seeing the process every day? Why aren't we making them an army of lean thinkers to solve their own problems? And we found that that, that, you know, it's not costly.

David Reid (23m 39s):

They're already doing the work and they're seeing the improvements. It's infinitely scalable, especially if you have a way where they can share ideas with each other and then it's way faster than, you know, it coming up to priority for, for a paid engineer to work on.

Mark Graban (23m 57s):

So I'm, I'm curious before we get into some of the process of how you engage the owner operators and, and the team members in different ways are, are, can you share some examples? Like you have some favorite examples of, you know, team member driven improvements?

David Reid (24m 13s):

Yeah, that's, that's a great idea. So, so I mean that, that they come up with great ideas. So I've got just a, a quick list of some right here. So Chick-fil-A has a mobile app that debuted about two years ago. And here's the deal with it. If you, if you pay with your phone like off of your credit card, then you automatically scan the app if you wanna pay with cash or you just wanna pay with a, a normal credit card not linked to your phone, well then people would often forget to scan their app, which gives them points for, for free food. And so what was going on, it was, it was really clogging up our, our system was that as this came thing came out and people wanted their points and they forgot to pay, they're standing in line realizing right after they paid that they didn't scan their app.

David Reid (25m 1s):

And at that point it's, you know, it's, it's already passed in the process or, or maybe they come back up later and they ask the cashier, Hey, I didn't get my points, how can I do that? And so our friendly team members would, you know, explain to that person one-on-one how you can go on website and, and get credit for that transaction. Well it was just taking up a lot of time and it might be really nice to that customer to explain to 'em, but the customer who's really just wants to order their food and keep going is now waiting on this thing that is not our main process. And so a team member came up with the idea that, hey, there's a customizable field that you can, you know, your store can decide what gets printed on it on a receipt, you know, a lot of 'em just say, have a nice day or something like that.

David Reid (25m 49s):

And they said, Hey, why don't we put the website on the receipt, every receipt, and then when a customer comes up, all we have to do is say, Hey, on the bottom of your receipt it'll tell you how to get credit for your order. And team member came up with that. They shared it on our, our lean Facebook site, which is how we share ideas. It immediately got 600 comments saying, wow, this happens in our store all the time. We need to do this. We liked it so much. We, we sent out a communication to the whole chain and said, Hey, here's this. And I would almost guarantee if you go into a Chick-fil-A today at the bottom of your receipt, it'll say, forgot to scan, go to this website. So there's, there's one of my favorites.

David Reid (26m 32s):

Another thing we had a team member who said, Hey, we make a lot of biscuits. Why do we only cookie cut them out one at a time? And so they actually welded six of our biscuit cutters together so that they could just press one time and get six biscuits.

Mark Graban (26m 50s):

Oh wow.

David Reid (26m 52s):

We had some concerns about that from a standpoint of, hey, you know, we don't know who's welding that, we don't know if that's food safe. We don't want welds, you know, pieces dropping off in the biscuits, but we love the idea. And so we actually took their idea and, and developed a plastic biscuit, multi biscuits roller that now you just roll it out like a rolling pin and it cuts every bit of dough into biscuits. Wow. Another one. So,

Mark Graban (27m 20s):

So, so it's like a six pack of, of cans or the similar kind of, I'm just trying to kind of visualize Yeah,

David Reid (27m 27s):

So no, the new thing that, that was the, that was the original prototype that a team member came up with. Yeah. We came up with is basically a rolling pin that has

Mark Graban (27m 37s):

Oh it okay,

David Reid (27m 39s):

Just roll it all the way across and you cut like 20 biscuits that by the time you've rolled it to the end

Mark Graban (27m 43s):

It's not even better.

David Reid (27m 45s):

Yeah, yeah. And, and you know, that's, that's the essence of lean is let's take, let's take an idea and build on it. So.

Mark Graban (27m 52s):

Well I love that. And I mean, from what I hear for one is challenging the way we've always done it. Biscuits have been cut, I'm sure everywhere, one at a time for a long time and someone challenged that and said, let's make the work easier.

David Reid (28m 5s):

Right, right, right. I I'll tell you one last one that, that I think is just like, it solves a need. One team member came up with the idea of creating a little rack to put all of our flavors of sauces in right at the cast register, because what does everybody do when they come? They say, what kind of sauces do you have? And, and you have to go over like our five or six sauces. And so now right in front of the customer eye, while they're ordering, they can see we got Buffalo sauce, we got Polynesian, we've got Chick-fil-A sauce, and and they don't have to ask the question anymore. They know exactly what we have. And it just speeds up that transaction a little bit and yet shows care for the guest at the same time cuz you're anticipating his need.

Mark Graban (28m 51s):

Wow. So those, I I love those examples Now, you know, to, I'm, I'm curious then in terms of creating a culture, like earlier when I asked what's the need or the opportunity for lean, you already described sounds like, I'm guessing corporate culture that comes from the executives of, you know, if we're not improving, we're getting worse or, or thinking about keeping ahead of, of competitors in a really competitive dynamic industry. I'm, I'm curious for one, tell me if that assumption's correct and then secondly, you know, because you have all the owner operators running their own businesses as part of the Chick-fil-A brand and you know, how, how do you, how do you then influence owner operators to, to utilize lean practices and to engage people when it's not the top down?

Mark Graban (29m 43s):

Well maybe I'm asking too many questions altogether, so maybe it's a step back. Thoughts on sort of the leadership that comes from corporate around never being satisfied. You can elaborate on that first.

David Reid (29m 58s):

Okay, good question. So I think, I think we have a culture of let's satisfy the customer. And so however we can improve to do that better, it is really table stakes. It like to be hired and you say, well how did that happen? I, I don't, we had an inspiring founder true at Kathy who was all about the customer. He chose operators to be in partnership with who were gonna take care of their customers. He hired staff who were gonna take care of the operators so they could take care of the customers. And then these operators went out and have selected team members who have that heart to begin with.

David Reid (30m 40s):

And then it's in reinforced by training of, Hey, this is what we're about here if, and, and, you know, if you, if you don't wanna take care of the customer, you probably don't fit in long term and, and probably self-select out. And so, so I'd say that's a, a culture piece of it. The, the next thing I would say is if you say, well how, how does that translate into people wanting to do lean improvements? We really present it as lean helps you solve the problems that bother you. And so we really start with felt need. So we don't try to dictate to operators, Hey, you need to, you know, shave off minutes here or you need to save some costs there or you need to reduce your inventory.

David Reid (31m 28s):

We don't tell 'em what to do. We basically ask them where where is your felt need? What would you like to fix? And we wanna come alongside you and give you some tools to help that. And at the team member level, really the question we ask them is what makes your job hard? And we kinda let them follow their curiosity and, and follow their pain points and, and just say, Hey, let's go after it and fix, you know, fix whatever's bothering you and and let's resource you to do that.

Mark Graban (31m 57s):

Yeah. So on, on that note, and I for one, you know, I love that philosophy. That's what I, I try to teach and coach others in that, especially in getting started with improvement fix what bugs you tapping into people's intrinsic motivation to, to do better for themselves and for the customers and for the company. And in your article, you mentioned the idea Paul Aker's book Two Second Lean is an influencer something you use to help introduce people to this concept, right?

David Reid (32m 28s):

Yes, yes. In fact, he, he's kind of a folk hero at Chick-fil-A. I think several of our operators have taken their teams out to his fast cap factory, I believe Washington. It's funny, I I just, I just clicked on one of his videos the other day and he actually happened to be addressing Chick-fil-A. So, so he had had enough interactions with teams coming from Chick-fil-A and, and this wasn't a corporate thing at all, this was operators taking their team members and just wanting to develop their team. And the, and the idea of Lean and Paul Acres had a shout out to Chick-fil-A and how, you know, how impressed he was with some of the things they were doing. So I I love his book.

David Reid (33m 8s):

It, it, it, you know, takes it down to the basic level of everybody can do lean, it's got applications in every area. And so we've definitely used that book. You know, he, he's such an enthusiastic speaker for it. I, I've, you know, listened to his book once a year on audio just to kind of fire me up of, Hey, are we doing everything we can be doing?

Mark Graban (33m 30s):

Well? And, and for listeners who are maybe new to this podcast series, Paul was my guest in episode 1 36 where we talked about two second Lean, that was back in 2012. So if you wanna listen to that, you can go to lean blog.org/ 1 36. And, and, and, and, and David, if you wanna, you know, you, you can tell people yeah, you, you and you and Paul have both been in the same podcast series that, that's, that might make some people smile there.

David Reid (34m 1s):

That's impressive. I'm, I'm in great company.

Mark Graban (34m 3s):

Yeah. So, so you talk about, you know, this idea of creating poll, I'm sure the owners and operators have things that bug them and then the frontline employees have things that, that bug them. And I, I'd like to come back to some of this, but one other dynamic I'm, I'm curious about in, you know, kinda, you know, a franchise owner operator model when Chick-fil-a corporate and engineers and you have innovations or improvement projects, how, how much of that is, you know, pushed on the owner operators where they have to accept that improvement or, I'm, I'm just curious how some of that dynamic works.

David Reid (34m 45s):

So yeah, obviously we're, when we're in the food service business, and this probably certainly applies to healthcare and other places, you can't have everybody just improving the process to the point that, hey, maybe we don't need to cook the chicken as long, maybe we don't need to cook it as hot. Maybe we don't need to use this kinda oil. You, you would quickly devolve into low quality, if not, you know, dangerous situation. And so, so we, so basically we have controls on how we let people do things. So, so we call that a sandbox and we have certain things you can work on, certain things you shouldn't work on, just cuz there's more information than a team member or a franchisee would have at their disposal that they could be changing.

David Reid (35m 37s):

As far as the idea of, of pull it, it, it really is because of this culture of people want, you know, to satisfy their customers and we kind of give them this fReidom to do it. There is a pull from restaurants to want to learn lean principles and so we've kind of taken the tack of, rather than pushing something out as far as a training, we, we kinda let them come to us and ask for it. And that helps our resources. If, if a store's not ready for it yet, they're focusing on other things, then, then we're not investing in in them that they're just gonna come learn some things and then let it sit on the shelf for two years. But the ones who are hungry for it come right away and, and get value out of it.

David Reid (36m 22s):

Is, am I answering the question you were asking? Well,

Mark Graban (36m 25s):

So yeah, I'm curious if, if it's something like let let's say, you know, engineers and and corporate decide that it, we we need to change some of the physical layout of the drive-through lanes to allow that exit. Like how, how much, I'm just curious in, in the agreement with the owner operators, how, how often can corporates say basically you need to do this, it's good for your business and it's gonna be part of the standard Chick-fil-A experience versus things that they have choice about implementing?

David Reid (36m 54s):

Great, great question. So really our secret sauce is our franchise model and, and the, the agreement that Inc has with, with franchisees. So I'll, I'll just throw out a couple of things. So first of all, yes, it does have to be a cohesive system. We want the Chick-fil-A experience to be the same everywhere you go. We don't want some group saying, Hey, we do full service and we do self-service and those kinds of things. We want Chick-fil-A to be y you know what to you're gonna get when you go there. Part of that is Inc pays for all of the facility, the restaurant and the equipment.

David Reid (37m 41s):

So like if we do come out with a new menu item that requires some specialized equipment, ink actually rolls all that out so that that doesn't put a burden on the operator to, to pay for some new piece of equipment. But then at the same time, so, so, so there are a lot of controls, but at the same time the strength of our operators is that they are incredibly entrepreneurial. So many of our breakout products have come from operators thinking up something. So many of our breakthrough ideas and pieces of equipment have come from operators saying, Hey, there's gotta be a better way than this.

David Reid (38m 25s):

So we really have a healthy respect for their entrepreneurial spirit. And there are meetings that go on all around the week of, hey, this operator has thought of this, do we have any concerns with him doing that? And then there's, you know, experts that say, Hey, how does this affect food safety, food quality, people safety, speed, space, complexity, capacity? We kinda look through all these lenses and and say, Hey, it's a great idea, but it, it's probably gonna change this and we don't wanna do that. And then what we'll often do is when somebody has a great idea, we will kind of inaugurate them as a partner with us and we will come in and observe what they're doing.

David Reid (39m 10s):

We will give some, some guidelines and sometimes we have to shut down tests and say, Hey, that's not the direction we want to go. Sometimes we say, Hey, this is such a great idea, we better, we better get on board with it and, and help, you know, accelerate figuring it out so we can roll it out to the whole chain. And there is just this healthy respect of, hey, operators are the ones who, who make the money, who served the customers who, who give us all a job. So let's, let's get behind what they're doing and and help them succeed.

Mark Graban (39m 42s):

Yeah. So can you elaborate a little bit? You, you touched on, and you elaborated on this in the article, you know, the i the the idea of sound bo sandbox boundaries, you, you mentioned some of it around food safety and, and the product, but can you share a little bit more about some of the things that are considered out of bounds and what happens if there's an idea that can't be implemented for some reason? I think you've touched on this a little bit, but I just wonder if you just kinda elaborate, maybe share another example.

David Reid (40m 13s):

Yeah, so some people who hear that we, we let 150,000 team members, many of whom are, you know, age 16 to 18, do lean improvements. And, and by the way, we make food that goes out to 3 million people a day. Yeah, that can get a little scary. And we have a very healthy respect for, you know, what, what the, the position that we're in in terms of serving food. And so basically what we did is we said, hey, we, we do need a sandbox of improvements that team members can do versus things that are off limits.

David Reid (40m 56s):

And so sandbox is just mean that that's the place you can play in. And so we have four boundaries that team members or operators are not allowed to cross. They can't do anything that impacts food safety, product quality, people safety probably should have said these in, in the right order. People safety, food safety, product quality or equipment warranty. And so if something affects one of those, we have the right and the responsibility to, to just say, Hey you, you, this has some unintended consequences and, and you're not allowed to do that.

David Reid (41m 38s):

So I mentioned a couple of things. If you were to say, Hey, let's cook the chicken for less time and we can, you know, we can be faster, no, that affects food safety or let's, you know, instead of holding something only four hours, why don't we hold it eight hours? No, that affects food safety so you don't have the right to play with those things because there's a lot of specialized knowledge that goes into whether that could be changed or not. And we've got people on staff who do that and, and we don't need, you know, team member level experimenting with things that they're just not, you know, qualified in, in changing.

David Reid (42m 18s):

So food safety, people safety, we have lots of great ideas that come up about, hey, let's store, you know, this box of of seldom used thing way up at the top of the restaurant and we can get more storage space in our restaurant. And we've just decided, you know, the risk of having to climb up ladders in the restaurant is not worth the extra storage space. And so we set guidelines and say, hey, don't don't store thing anything above this height in the restaurant and things like that would be an example of food safety. Product quality. Had a team member who came up with a great idea of how to re had a mixed lemonade, same ingredients, same ratios, but to save the time of water filling up the bucket, he was gonna add things in a different order.

David Reid (43m 7s):

And it turns out the order is important. It, it helps the sugar dissolve when the lemon juice is already in there. And so we said, Hey, great idea, thanks for thinking of ways to do it faster, but to get our signature taste, we need to put the ingredients in this order. And then the last one's equipment warranty. So one idea that came out was, and and it is funny when, when these ideas come out and you don't think through the consequences, they they tend to go viral very quickly. So people all of a sudden every restaurant's turning the vent hood on the bottom of their ice stream machine around to face the back to face the wall. And what it was, the advantage for them was it no air wasn't blowing out the bottom of it blowing napkins and bags around anymore.

David Reid (43m 54s):

The bad thing was it was designed that way so that the hot air would get away from the machine and not just collect behind the machine. And so we saw that check with a manufacturer, they said, yep, nope, we, that'll wear out the motor faster. And so we had to issue a polite cease and desist to say, Hey, don't, don't do things that avoid the equipment warranty.

Mark Graban (44m 15s):

Yeah. So I mean there's a couple elements I I I hear you saying there. One is feedback loops and, and Kaizen doesn't give people carte blanche to do whatever they want. That sometimes you need to give feedback. In your lemonade example, it sounds like there's kinda this respectful process of instead of just saying don't do that, of explaining why and, and helping people understand why the order matters, which seems to be an important part of a respectful lean culture. Right,

David Reid (44m 50s):

Right.

Mark Graban (44m 52s):

But your your, your lemonade example made me think of, and it's been a while and some of the people I knew at Starbucks have left, but you know, Starbucks, Tim Horton's, some other, you know, fast service restaurants have embraced lean to different degrees and, and the one example when some of the Starbucks lean leaders, someone in a parallel role like yours, we would go to a one of the Starbucks stores and they would point out one of the ideas that baristas might use to speed things up is to brew the espresso directly into the paper cup. Right? The beverage is gonna be made into, cuz you think, oh, well that eliminates a step and we, we, it eliminates motion and we don't have to clean the espresso shock glasses as much.

Mark Graban (45m 36s):

But that's another thing where Starbucks was convinced that the method really mattered. It wasn't just the ingredients all getting into the cup that brewing the espresso into a shock glass changed the nature of the espresso, which affected drink quality. And they would have to explain to people, I see, I see where you're coming from that yes, this is more efficient, but here's why that's not really the right idea for quality or for the customer. So I think dynamics like that are, are really interesting. We've got people who are motivated and so I I was gonna ask you kind of along those lines, like there's this expression you used in the article I was gonna ask you to elaborate on, I'd much rather have to restrain mustangs than to kick

David Reid (46m 20s):

That's right. So, so I I love that Starbucks example you just gave that that's really part of their differentiator and you know, i i if you're not thinking holistically, you could say, oh well that's waste if they could reduce some motion and some steps. But if that's what the customer wants in terms of a better tasting drink or even a theater of, hey, this is done with high quality stuff, not just into a paper cup, then that's part of the value proposition and and it's not waste. So I I love that. And, and then back to your point of I'd rather restrain mustangs than kick mules. You know, we're, we're never gonna have it perfect.

David Reid (47m 3s):

Like I like you, if you say, Hey guys, we want ideas from you, but then you punish people when they come up with an idea, you, you're gonna shut down and you won't get ideas. And so you, you're gonna have it one way or the other of people just who don't try to innovate. And we believe absolutely, if, if one of the eight waste is our own team members creativity and skills, I, I think about we have 150,000 eyes looking at our process every day, skilled at it, understand what we're trying to make, understand, you know, where the pain points are.

David Reid (47m 46s):

We would be crazy and, and extremely wasteful to not enlist that army of people who are experts on the process to improve the process. And so yes, there will be some times when we have to say, whoa, whoa, whoa, whoa, let's don't do that, but there's gonna be, you know, a thousand times more that they're gonna come up with something that is totally fine and the company didn't have to spend a dime to for that improvement to happen in that restaurant and for them to share that and other people see the value of it and it just happens organically that we're doing things in a better way or they come up with a breakthrough that, you know, we add some resources to and, and come up with the next big thing.

David Reid (48m 35s):

So, so we would much rather have all these people improving the process. And we haven't talked Mark yet, so most of this comes to light through a Facebook page and yeah,

Mark Graban (48m 49s):

I wanted to hear more about that.

David Reid (48m 51s):

Yeah, so, so I, I'll kind of introduce it this way. There are people who, who still just like, you know, especially in the fact that we're in food service, they, they're like, oh, that sounds so risky to, to let team members do that. And my answer to them is they're doing stuff anyway, at least with the Facebook page and a reward system and a way to share ideas and be recognized. At least I have some visibility into it before they would've just done it and I wouldn't have known it was happening. So yeah, so it's, it's, it's actually no more risky than just, you know, not having a way to share ideas.

Mark Graban (49m 27s):

And so then Facebook site is used for people, they, they can like ideas, they, I mean, how, how often do you see ideas, improvements, just spreading organically through that communication platform?

David Reid (49m 44s):

Yeah, so, so what what the way we introduce lean to our, our restaurants is an operators interested in it. He asks for a one day class, somebody goes out and teaches his class, teaches a class in maybe 10 restaurants and you know, several key team members who are very influential in their stores come and the operator comes and they teach 'em one day on how to see waste and some tools to improve waste and things like that. And so at the end of that day, they are told about an internal Facebook page, it's called the Lean Initiative, chick-fil-A Lean Initiative Facebook page.

David Reid (50m 28s):

And you get invited to it once you've been through this class. And so everybody's kind of got a basic understanding of lean and what, you know, what kind of improvements go on there. We've kind of said, hey, to keep this site pristine about improvements, don't go on there and just ask, Hey, where do you guys order this? And you know, don't, let's, let's keep it that every post is a meaningful post about an improvement. And so what happens is team members just for the love of their job and for the love of wanting to help another restaurant, you know, do something that they figured out, they, they put a picture and a post describing an improvement.

David Reid (51m 8s):

And so it can be the way they've organized their condiment shelves. It can be, you know, how they put a combine system in for things that they only order once in a while. It can be the scan forgot to scan, put that on the bottom of your seat. And then what happens is everybody sees that and it, it becomes this thing where if you like it and you say, Hey, I wanna do that in my restaurant, you can just hit it. Like you can say, hey, I, a lot of people times people will tag people in their restaurant that will be responsible for that area to let them know about it. So the more likes and comments a post has, it generally means, wow, that was a great idea.

David Reid (51m 53s):

And so I have an engineer who goes in once a month and just looks at everything that's been posted and there's usually about 60 posts a month. And then, you know, there'll be one or two of 'em that kind of went viral, will have, you know, more than a hundred likes. And the other thing that happens is they self-police each other. So, so when somebody says something that, that somebody else can recognize, hey, that's not food safe, people safe is gonna hurt product quality or is gonna avoid equipment warranty, they'll police each other and a and an operator will come on and say, Hey, I don't think that's a good idea. You shouldn't do that for this reason. And then, you know, by the time three other people pile on and say, yeah, let's don't do that, well then that kind of serves as a, hey, don't, don't do that.

David Reid (52m 39s):

And, and they kind police themselves.

Mark Graban (52m 42s):

Interesting. Wow. Yeah. I wonder, I I'm curious, I'm, I'm really curious how many other companies are using Facebook as a platform like that? I guess your employees generally already have access to Facebook and you're able to keep that private. There's no con i i I guess that seems to be working well for you.

David Reid (53m 2s):

Right? It and you know, that actually was there, there was this dream of we need an app where team members can take pictures and post them and vote up vote ideas and that kind of thing. And, and some operators said, well, we don't have a year to wait for you guys to come up with some app that every team member could have on their phone. We're just gonna use Facebook. And that was one of those lean improvements of why invest a whole lot? Here's this tool that will work for what we need. And we were not in the business of saying, no, you can't do this. I I, when it started and it went viral, I put an engineer on it and said, every month on the last day of the month, I want you to summarize everything that's been on there.

David Reid (53m 46s):

If there's anything that is, you know, dangerous or something to be concerned about, I want, you know, you to send that up through the chain to who, who might need to speak into it. And it, it's just worked out fine. And again, the the, it's the idea of, oh, that sounds a little bit risky, what if a team member writes something on there that you know, ends up being not the right thing to do? And, and again, my answer to that is, well they were probably doing it anyway. At least now we have visibility into it and can and can take some action.

Mark Graban (54m 15s):

Yeah. Well, so the last question I wanted to ask and, and we we can wrap up on this. You, you mentioned rewards and I'm, I'm curious if you can sort of talk about why it's important to celebrate wins to celebrate participation. How, how do you find a balance between recognition rewards, both?

David Reid (54m 37s):

Yeah, that's a great question. I, I think our, our goal as a company is, you know, we wanna, we wanna encourage people to do things that, that help us with our goals. And certainly lean improvements are, are key to that. And so we just wanna celebrate good work. And so the, the way we do it is very often is through the Facebook page. When, when, when the idea came up about putting the forgot to scan text at the bottom of your app, the company and this, this wasn't had any, didn't have anything to do with engineering.

David Reid (55m 19s):

It was somebody in marketing said, Hey one, we need to make an article and tell every restaurant they can do this cuz not everybody's on the lean Facebook page. And two, we ought to celebrate that team member who came up with the idea. And so they went and found out, you know, who originally thought of it and posted on the lean Facebook page, they made it an article about lean improvement. They made it an article about here's a great idea, you know, and so that team member, he probably didn't get any money or anything out of it, but he got recognition that the whole company thought what he did was a great idea. We've also done some contest. I love it. So, so we had an issue that my engineering team was thinking about of, we got so many dishes and some of 'em are only for breakfast and some of 'em are only for lunch dinner.

David Reid (56m 5s):

And, and team members are telling us it, it takes a long time to close the restaurant at night and get ready for breakfast in the morning. And so we had ideas of, hey, I'm sure there are people who are doing this better than, than we even know how to think about it. And so we ran a little contest for a month and said, Hey, we want your best ideas on how to transition from dinner at night till breakfast in the morning. We want time saving ideas, we want how you, you know what checklist, whatever you do. And we're gonna give a hundred dollars gift card to whoever gets the most likes. And so it kind of created this fun little competition.

David Reid (56m 47s):

You had all these ideas coming outta the woodwork of how people conbon their dishes, how people set up a cart that, you know, everything that needs to come out in the morning, they leave in the same place and so you're ready to set up in the morning. All these great ideas and team members got to comment on each other and build off of their ideas. And so for a hundred dollars and we celebrated the person who who won it, we did a little video interview with them and thanked them for their idea and we generated a ton of ideas for us to, you know, sift through and decide what what might be a a whole chain-wide program.

Mark Graban (57m 27s):

Well, it's very cool to hear about what everyone is doing at Chick-fil-A. And, and, and David, I wanna thank you for taking time to, to, to be on the podcast to share what's going on. And I, I think it's all really exciting. So do, do you have any, any other kind of final, final comments for the listeners?

David Reid (57m 48s):

I tell you, I, I think Lean is a, a great tool set. I think it's a shame if everybody in your company's not using it. We've found that team members want to know, we feel like we're building in them a valuable skillset for the future if we train them on lean. And I, I think the thing that's been the most surprising to me is our Lean Kickstart, which is a one day class, like from nine to four, where we bring team members in from different restaurants. We tell them what lean is. We spend about two hours on the eight wastes. Then we challenge them to make a list for like five minutes of waste in your restaurant.

David Reid (58m 33s):

Then we share that list that came outta that one class with every group. And so they all end up with about 60 wastes that they have thought of in their restaurants. And then we teach them five s, we teach them spaghetti diagrams. We teach them how to, how to measure things with pedometers and stopwatches and those kind of things. And, and then we kinda have just a, a, a, you know, by the end of the day you're equipped to go and start a project and then there's a couple of paths if you want, go deeper. And we have seen so many complete culture changes in the restaurant of people looking to improve waste in, you know, to, to reduce waste in their restaurant.

David Reid (59m 18s):

And I, I think it's going to just get bigger and bigger over time. And it's gonna be a competitive differentiator for us that when you have a whole team of frontline workers who are thinking about the process through the eyes of lean, you're just gonna leave everybody else in the dust. And so I think it's, it's something every company should make sure that their frontline people are thinking that way.

Mark Graban (59m 46s):

Great advice. Whether, whether you're a gazelle or a lion, either way. David Reid has been our guest today, author of an article that was published in the IISE Magazine titled From Lean Modules to a Lean Mindset. Chick-Fil-A success shows how leveraging your greatest asset speeds up cultural change. And unfortunately, I believe the article is only available to, I, I se members. That was one of the reasons why I wanted to do the podcast and, and sort of help share these stories for those who, who can't see the article. But David, thank you again so much for your time. Really great talking to you, and thanks for what you shared.

David Reid (1h 0m 26s):

My pleasure, mark. Thank you so much for having me. And they did give me the article to post like on my LinkedIn, so you can see it on my LinkedIn. David B. Reid, r e i d.

Mark Graban (1h 0m 38s):

Oh, great. And I will definitely, for, for listeners, go to the blog post for this episode and I will make sure it's pointed to, to David's LinkedIn page and that'll help others read it. So thank you. Thank you for mentioning that, and thanks again for being the guest.

David Reid (1h 0m 53s):

Thanks, mark. It's been great.

Announcer (1h 0m 57s):

Thanks for listening. This has been the Lean Blog podcast. For lean news and commentary updated daily, visit www.leanblog.org. If you have any questions or comments about this podcast, email mark at leanpodcast@gmail.com.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Mark – Great guest and podcast. I liked the observation that a form of waste may be identified, but that step or process is of value to the customer, it is not waste.

Great interview Mark. As an Atlanta native, a full-fledged Chick-Fli-A fan, and a full-time lean practitioner, I loved having my worlds collide in your interview.

Those of us who make our living doing process improvement know that none of the wonderful things David spoke about would happen, without an incredibly strong culture of servant-leadership. I’ve been to many CFA’s across the country and seen leaders doing what ever it takes to serve their customers. As I understand their system, CFA franchisees (operators) have to work in a store for at least 1-year, before they are “eligible” to spend a substantial amount of money to become franchisees. This one step ensures that future leaders “get” the corporate culture.

I heard a couple of wonderfully surprising things as well. Hearing that CFA corporate funds big changes to the restaurant / capital equipment is awesome. I was happily amazed to hear that field leaders can ask AND GET someone from corporate to come to them to teach lean principles. Wow! Both of these actions demonstrate far-sightedness and wonderful leadership in an era where companies have been working for decades to hammer out every expense that will not return hard-dollar benefits in the current quarter. (maybe a podcast on how this attitude is incompatible with lean’s “respect for people” tenant is in order?)

Adding Lean this wonderful culture will surely result in CFA becoming the world’s largest and most loved place for fast good food in the very near future!

Thanks again Mark!

Thanks, Bob. Glad you enjoyed it!