We discuss the “transformation model” presented in the book, which provides a framework organizations can adapt to their own context. John shares examples from health systems that are redesigning care around value, engaging their people in daily problem solving, and achieving world-class results in safety, quality, and cost.

Streaming Player

In the podcast, we discuss topics including:

- How often does John find leaders who are willing to admit they need to be “mended” or that they need to change their approach and model Lean behaviors from the top?

- Why does the Affordable Care Act help get leaders interested in Lean?

- How do values and principles drive systems and Lean improvement? Read more about the Shingo Model that he mentions.

- Why is focusing on “ROI” problematic for a Lean transformation?

- How can key support departments, like finance, and HR, become partners in the transformation efforts?

- What role does the health system Board need to play to drive Lean transformation?

- How can manufacturing leaders get involved as possible Board members?

- Is it easier for John, as a former hospital CEO, to influence other CEOs?

- How does John see prices in healthcare becoming more standardized or transparent to patients and payers? Read more about “reference pricing,” as mentioned by John.

John was previously a guest for episodes #184, #159, #146, #72, #62, and #54 going back to 2008. His previous books, which I highly recommend, are On the Mend and the follow up Potent Medicine, both are Shingo Research Award recipients.

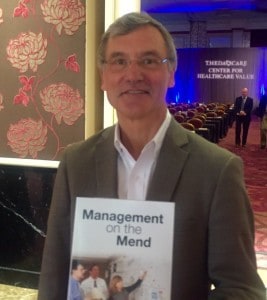

You can buy the book through the ThedaCare Center or as a Kindle book via Amazon.

For a link to this episode, refer people to www.leanblog.org/225.

For earlier episodes of my podcast, visit the main Podcast page, which includes information on how to subscribe via RSS or via Apple Podcasts. You can also subscribe and listen via Stitcher.

Transcript:

Mark Graban: Hi, this is Mark Graban. Welcome to episode 225 of the podcast for July 22, 2015. Joining me once again on the podcast is Dr. John Toussaint. He's the founder and CEO of the ThedaCare Center for Healthcare Value. We're going to be talking about his latest book that's titled Management on the Mend.

John wrote this new book to document what he calls the core elements of successful lean transformations that he's seen not just at ThedaCare but at other organizations around the world. We're going to discuss topics including how often does John find leaders and executives who are willing to admit they need to be mended, as his title implies, Management on the Mend. How do values and principles drive systems and lean improvement? How can key support departments like Finance and HR become partners in transformation efforts? And what's the role of the board in driving lean transformation?

John is going to talk about all of that. He's going to talk a bit about the transformation model that's in the book, and I would certainly encourage you to buy the book and read it to learn more about the elements of that model. Again, the book is Management on the Mend. If you'd like to find links to learn more or purchase the book as a hardcover or a Kindle version, you can go to leanblog.org/225. Well, John, thanks again for being a returning guest here on the podcast. Thanks for joining us today.

John Toussaint: Thank you, Mark. It's always fun.

Mark Graban: Well, you know, you've got a new book out and it's always fun talking about what you're doing and what you've been writing about. So maybe we just jump in and talk about the new book, Management on the Mend. As a follow up to your previous books, can you tell the listeners how this book came to be?

John Toussaint: Well, we've been studying a number of organizations around North America. I spend a lot of time visiting organizations. And what we have been finding is that there are some core elements, some core characteristics of successful lean transformations across the industry. So what we wanted to do was write a book about the framework of the successful lean transformations. We're really talking about the whole transformation here, not just one component of it. So this book is the compendium of knowledge from the center, from my organization, the ThedaCare Center for Healthcare Value as we know it today.

Mark Graban: How do you gauge successful? I mean, how would you describe something you would consider to be a successful lean transformation?

John Toussaint: Well, as you know, lean is about getting results. I mean, the only reason that you would go through the change process required to transform your entire organization is to deliver better results. What we were looking for is organizations that really had significantly better results and then what they had done from the standpoint of their lean journey to achieve those. So, for example, the Palo Alto Medical Foundation used their redesign work to actually become the number one set of clinics in California related to customer quality and service. And that was rated by Consumer Reports, which has been spending a lot of time throughout the country building consumer reports for healthcare clinics. And so we were looking at where world-class performance is going on and then studying those companies.

Mark Graban: And it's to say in the book, this is kind of a balanced scorecard, if you will, of measures around safety and quality and access and cost, kind of across the board results. Not just, you know, a lot of people often focus on looking for cost reduction. Clearly there's more to it than that, right?

John Toussaint: Yeah, I think we still have a lot of site visitors. And you know, the one thing I tell them is if you're coming to try to learn this methodology so that you can take $200 million out of your cost structure, you're probably not going to be successful. Because as we all know, this is about redesigning processes to deliver better value, which means taking waste out of the process of care. You should see improved quality, reduced cost and improved staff engagement. All three of those things are critically important from the standpoint of measuring success. And if you're just looking for cost reduction, this isn't the methodology for you.

Mark Graban: And there's old habits around that. Organizations that have been in cost-cutting mode and a lot of that comes through laying off staff, and you and I have both seen that Lean, of course, is a great alternative to that strategy. Organizations that are reducing costs through quality and safety improvement, they're making no-layoff commitments. So organizations that are adopting that, they're examples of management on the mend. Back to your book title. And so I guess my question is, how often do you find where managers or senior leaders are willing to admit that management needs to be mended? Is that a controversial thing to propose to them? What are you seeing out there?

John Toussaint: I think that with the advent of the ACA and the other changes with the recent SGR fix in physician payments, that most executives now know that we're not going to ride the volume horse anymore, that we're going to have to move to value. And that in combination with the reduction in payments that are coming from Medicare over the next few years, has really led the executives in healthcare to say, “Oh boy, what we're doing now isn't going to work in this new world. Is there a better way?” And so I think it's really driven a lot of interest in the lean methodology as an option to transform the culture. There is a lot more interest today than there ever has been from the executive standpoint. Now, interest doesn't necessarily equate into results or successful transformations, but that's where it starts. I mean, we have to be curious about, “Hey, is there a different way? Is there a better way?” And of course, now we have a lot of organizations around North America that are applying these principles and become very successful. So I think this really is a movement in the management realm of healthcare. And I only see it accelerating.

Mark Graban: And do you find it's easier for you, as a former hospital CEO, to talk with other hospital CEOs about the need to change and how that starts personally with them? Do you find that it at least helps bring up the issue? You have your own experiences to talk about?

John Toussaint: Well, I mean, you know, it's human nature. The CEOs want to talk to CEOs, and I sat in that chair for a long time and we were successful. So, I think that it's helpful to have somebody that's sat in the chair, so to speak, to be able to answer some of the questions. But the reality is, as we all know, this is learning by doing. So even somebody that sat in the chair is not going to be nearly as successful as a CEO that's actually out there doing something. And so that's what I always suggest. We just have to go do something. That's how we're going to learn. And if there's enough curiosity on the CEO's part, then I'm happy to try to get involved and help them along on the learning journey.

Mark Graban: And like you said, just interest isn't enough. We need activity, but at the same time, people are under a lot of pressure. We probably want to minimize the number of failures or struggles people have with lean. And so let's come back to the book and talk about the transformation model that you laid out in the book. Before we dive into some of the details, can you talk about the idea of a roadmap or a model and sort of how you came to develop that based on the experiences at ThedaCare, what you're seeing in other organizations?

John Toussaint: Yeah, I think this is well beyond the experience of ThedaCare. The book really focuses on 11 different organizations and the success that they've had to date. And I think that what we are finding in the successful organizations is that they are following a framework. There's not one prescription for the Lean transformation. It's situational because every organization is different. But what we tried to do was identify what is that framework for success. And then within that framework, we gave several different types of examples. So the chapter on the central improvement office, I mean, I gave three examples of how you might put that together, three successful examples, really quite different from each other. So I think it goes back to the principles. And of course, the principles we teach are from the Shingo Institute. We believe that those principles are the core of any Lean transformation. And that's what we focus on. And then the book lays out the different activities that organizations need to be focused on that really fit the framework.

Mark Graban: So for people who aren't familiar with the Shingo Institute and the great work that they're doing, what are some of those values and principles that these successful organizations incorporate into their approach? Or are there any of those principles that some organizations miss, unfortunately, that lead to different problems?

John Toussaint: Well, I think we can talk about a few examples of those, but I think the essence is that principles are actually, once you establish principles in your organization, you can build the systems that then change the organizational behavior, the individual behavior of the people that work there. And that's pretty much the fundamental thinking behind the Shingo principle. So let's take the principle of lead with humility, which quite frankly, I find little of in healthcare. It's all about image and power, and bigger is better. Lead with humility is a principle that drives a different type of system than what we've seen in traditional American healthcare. And then obviously, different behavior in the scientific method to solve problems is another key principle. So what we're saying there is that we're going to build a system of PDSA thinking, which then is going to change the behavior of the individual individuals that work in the organization to always be using PDSA thinking to solve problems. I think those principles then really begin to redesign your organization. And that's why I spent a whole chapter on principles. I spent the chapter on values and principles. So values are different. Values are sort of the deeply held beliefs of an organization. So, you know, the example I use is Paul O'Neill's belief that true respect for people is we should never injure any of our employees. So when he took over at Alcoa, he made it clear to the Wall Street shareholders and everybody else that his focus was going to be on employee safety. And over the next few years, he made Alcoa the safest company in the world. And guess what else happened? It became one of the most profitable companies. So again, I think there's the values. What are those deeply held beliefs? And then there's these key principles behind the lean transformation that are critical.

Mark Graban: Well, the whole idea of humility comes through very strongly if you spend time with Toyota. There's a great book I really like. I think a lot of people don't know about it. It's called Toyota by Toyota. And it was written by a number of authors and team members and leaders from the plant in Georgetown, Kentucky. And chapter one of the book is completely about this theme of leading with humility and how the manager who wrote that chapter really had that emphasized as they were brought into the organization about how important it was to lead with humility. And, you know, that's maybe less. It's not as easy to see. Somebody comes and visits an organization, they see tools and methods, maybe they see systems. It's harder to see those underlying principles and philosophies unless they are manifested in some way.

John Toussaint: Well, and I think that's what's missing in most organizational transformation is they miss the core elements of the leadership changes that need to happen. So that principle of lead with humility is clearly one of them. But then there's also, and we spend a chapter on this in the book, the actual management system by which we can actually lead the organization. So what is that standard work from top to bottom within the managers and leaders of the organization that are going to lead to delivering better value for the patient? And that's another thing that we find missing is very, very few organizations have actually defined what that leadership standard work is.

Mark Graban: Now that leader standard work is a big part of one of the parts of the model you talk about in the book is the idea of a frontline management system. If you're talking to somebody who knows nothing about standard work for leaders or what that system is about, how would you describe that in a nutshell to them? What do you mean by a frontline management system?

John Toussaint: Well, every day everybody who has a leadership and management position in the organization should know what they are going to do to deliver better value for the customer. And it's different at different levels. So if you're a frontline manager, you're going to be focused more on how do we actually identify, how do we train our frontline workers to identify and solve problems every day? I didn't say to solve the problems every day. I said to train the people who are actually doing the work to identify and solve the problems every day. So that's what the middle manager might do. At the vice president level and above in the executive team, it becomes more about alignment and barrier removal. So we need to get to the Gemba so that we understand. So again, standard work, we're going to the Gemba, we're going to see and ask questions and show respect. And what we're looking for are opportunities to remove barriers so that our frontline managers and ultimately our frontline workers can identify and solve problems every day for our customers. So it's important to realize that at the top of the organization, or I actually like to think of it as the bottom of the organization. When I was the CEO, I was at the bottom and I was actually supporting the people at the top who actually add the real value. My job is to make sure that I have not inundated them with too many initiatives. I see that all the time. I've made it very clear what the True North metrics are, just a few. What are the things that really matter to the organization? That I get to the Gemba and that I understand where the barriers are that only I can remove.

Mark Graban: And to your point of too many initiatives, I thought one thing you stated really clearly and compellingly in the book was the idea of not overburdening people, not overburdening managers and staff, and that it's disrespectful or it's not a good example of respect for people to try to ask too many people to do too many things. So how do you work on trying to convince people to have a greater sense of focus and what they're working on? Because there are a lot of problems to solve, right?

John Toussaint: Yes, but it's one thing to solve problems, it's another thing to create initiatives. And what we find is that organizations have way too many initiatives. So, for example, I was in an organization the other day and we asked them how many initiatives they had. They wrote them out on yellow stickies, and there were 242 strategic initiatives. There's no possible way that we're going to get 242 strategic initiatives done in my lifetime, let alone in a year. Yet those executives are not the ones that are doing the work. They pass it off to the next person who passes it off to the next person, and finally it ends up on the lap of the people that are actually trying to add value to our customers every day. So it's really important at the senior executive level to clearly state what those initiatives are and get as many of them off the plate as we can so that we can spend more of our resources at the front line identifying and solving problems that really matter.

Mark Graban: Yeah. And I've seen a number greater than 242 at another health system going through that similar initiative. And I think when they start reflecting on what they've done in the past, they realize that they have such a long list of initiatives and they're not being completed. So it's better to have a small number of initiatives that they can actually complete and then move on to the next. I remember all the visits to ThedaCare, seeing the very publicly displayed wall that talked about the initiatives that were being very purposely put on hold, deselected.

John Toussaint: Right. It's very hard to deselect, but very important.

Mark Graban: So one other thing that I thought was really interesting in the book, we've talked already about not focusing too much on cost reduction as a primary goal, or not focusing only on cost reduction. You talked a lot in the book about ROI, why that can be problematic. So I wonder if you can talk to the listeners about that.

John Toussaint: Well, we had to prove to ourselves, and this is I tell you what we did, not what you should do, but we had to prove to ourselves that the lean journey was actually delivering results, financial results. And so my CFO, when I started as CEO, actually measured the return on investment for the first couple years of our lean activity. Unfortunately, what he was measuring was the results of Kaizen and value stream mapping and that sort of thing, not the actual results of the organization overall from a cultural standpoint and a quality standpoint. And, you know, we found that, and this has been true of most organizations, or this has been true in the articles that have been published about this in healthcare and certainly outside of healthcare, is that the return is about three to one if you're successful. And in our case it was like five or in one year it was nine to one. So it's not so much about measuring the ROI as it is about making sure that you're actually successfully transforming your organization using the methodology. I would much rather people focus on, “Okay, how do we know whether we're actually transforming the organization versus how much return are we getting?” Because if you're doing the transformation in the framework that we've laid out and you're successfully doing that, you're going to get the return. We don't have to keep reinventing the wheel here. And ROI simply takes valuable finance resources off where they should be, which is in the Gemba, helping the managers understand their financial performance and improving it.

Mark Graban: So let's talk more about finance and maybe some of the other support departments that you write about in the book, the need for them to be key partners in a transformation. So what does it mean? Or how does finance more directly support a lean transformation? Getting out of the office and being at the Gemba. Do you have some examples of what that might look like?

John Toussaint: Yeah, we had our finance folks sitting in their office as cops. So you didn't meet your budget and we're going to get finance to come and beat you up. The finance people hated that role, and I hated that role for them. So what we decided was what we're really trying to do is improve financial performance. What's the best way to improve financial performance? Not to act as a cop, but to actually act as a team member on a management team that's focused on improving financial performance and quality performance and staff engagement and customer loyalty and all those things. So we started the process of trying to eliminate the budget because we felt that that was a lot of wasted finance time. And if we could get rid of that, we could redeploy those finance people to the various frontline units to help them understand their financial performance. It took a few years to get that done, but in 2010, ThedaCare did move to a forecasting process. It freed up quite a few thousand hours, about 10,000 hours of time of finance people to actually then work with the team members on the front line in the different departments, whether it was the ICU, the emergency room, or the clinic. And once we were able to redeploy those finance resources to where the work's being done, guess what happened? Financial improvement. And, you know, this is what we wanted all along. So when we stopped having our finance people be cops and started having them be part of the team, they were very helpful.

Mark Graban: Well, and I think there's probably a more general lesson about that as well, not just for support departments, but back to the role of leaders in a frontline management system. What you said reminded me of someone I know at a hospital in Dallas where he was in the hospital lab. They had asked him pretty much every year for eight or nine years, “Hey, would you like to be a shift supervisor?” And he always said no until they started, you know, through their lean transformation and change in the culture. He finally became a shift supervisor because he said the role was redefined from being a cop to being a coach. He didn't want to be a cop, but he was more than happy being a coach in the way you described earlier of helping eliminate barriers instead of just finding fault or blaming people. I think that that's a huge part of that lean transformation.

John Toussaint: Absolutely. It's a whole different role, and it's a much more exciting role for all people to play, whether you're in finance or management or HR or IT, whatever. I mean, don't you want to be on a team that supports the improvement of the value to the patient? I mean, I think that's why we go into this business.

Mark Graban: Yeah. Well, there's that incredibly powerful purpose and intrinsic motivation in healthcare. If we allow people to rediscover that or if we tap into that. I'm sure that focus is there. Finance people are working. I assume in finance at a hospital instead of someplace else, because they have a connection to that mission. Same with HR, right? So can you talk about HR for a minute? What are some of the ways that you see HR departments contributing to a lean transformation?

John Toussaint: I think it's really important to get these administrative service areas on board early in the transformation, which is why I spend half of the book on the administrative service areas, because hardly anybody ever writes about them, but yet they're absolutely critically important. Finance is certainly one of them, and HR absolutely one of them. And guess why? Because really all lean is, is a people development system. And HR has a lot to do with people development. So what we have to do is define first of all what we are developing people to become. So what are those competencies? What are the traits of the type of worker that we're after hiring and make sure that we're actually hiring the right people, that we're developing those people effectively to be able to identify and solve problems every day, or if they're a leadership role, understanding what is expected of them from a standard work perspective at whatever level that they're at. But in addition to that, we've got all these other things that are so critical, like you mentioned earlier, the no-layoff piece. Well, guess what? If you're going to have a no-layoff philosophy, you better have a redeployment plan. Guess who develops the redeployment plan? It's the HR folks. And I showed at the summit this year, a pretty sophisticated process that a lean organization uses to make sure that we don't let anybody go due to improvement work. So, you know, there's just a number of things that are critical when it comes to the people side of this, not to mention the whole management training, the management system, which HR is definitely part of as well. So it's very important to have them as a team member.

Mark Graban: Yeah. And one other group, it seems that's critically important is the board. Do you see organizations where the board is more directly getting involved, both maybe from the standpoint of challenging the CEO and the other leaders who report to the board, challenging them to find different ways of driving better performance, but at the same time trying to be supportive and remove barriers? Can the board drive and model some of those behaviors, or does the board at best just stay out of the way?

John Toussaint: Well, it's interesting. I was just this morning, I was with a CEO from a Michigan hospital, and I asked the question, “So is your board on board with this transformational journey that you're thinking about?” And he said, “I've had like three of my board members say it's about time.” So I think that boards are actually becoming more sophisticated. Those guys on his board were actually from manufacturing. And as you know, there's a lot of great lean manufacturers in Michigan. And so they know that if they didn't use this method, they would have been out of business years ago. And they are sort of amazed that somehow in healthcare, operational excellence has not been a focus. So I think we're seeing more and more, and I do a lot of work with boards, but I'm seeing more and more boards really not only understanding what we're trying to accomplish, but actually quite on board with it. Now that's not true of all the board members, but usually there's a couple people on these not-for-profit hospital boards that deeply understand this method and they can bring the other board members along. They can help, they can teach. And it's the board's role to support the CEO in making this happen. Because everything doesn't go swimmingly. We have problems along the way. People don't like change. This is transformational change. The doctors sometimes aren't going to like change. And the board has got to be there to support the CEO when stuff happens.

Mark Graban: And yeah, there's a clear pattern where if you look at the ThedaCare story, as you wrote about in your first book, On the Mend, if you look at the Virginia Mason Medical Center story, they had, like you said, people on their boards who had something to teach, but they had certainly skin in the game that they were paying for the healthcare costs for their employees and they were motivated to help. Do you have advice? You know, I know a lot of manufacturing leaders out there who I think would be interested in trying to help. But what advice would you have for them if they had interest in trying to get on a hospital board? How might somebody go about doing that?

John Toussaint: You know, every situation is different, but I think that CEOs in today's world are always looking for board members who can contribute and contribute from a strategic standpoint, contribute from a teaching standpoint. And if you're in an organization, you're a lay board member, but you run an organization or you're at an executive level in an organization that's actually been through this transformational journey, you can be very valuable to these hospital leaders. And I think you just make it clear to the powers that be that you're interested in participating and interested in helping. We got a number of people like that on our board that, you know, they raised their hand, they said, “Listen, healthcare is important. It's important to my company, it's important to me. I want to participate, I want to add some value.”

Mark Graban: And so does a lot of that, do you think, come through just networking in the community or somebody could reach out and try to make an appointment to try to meet with an executive or figure out what event they could attend?

John Toussaint: Yeah, I had people, I had community members from these companies that would from time to time come in and meet me or I wanted to meet them. I think it's perfectly reasonable to call up the hospital CEO and say, “Hey, I'd like to come and talk to you and see what you're doing.” I mean, most of these organizations are not for profit, supposed to be focused on the community. Well, we better listen to the community leaders.

Mark Graban: So I've got a couple of questions in the time that we have left that came from people via Twitter. And one of them, Paul Critchley, Paul asked, “Do you see Lean playing a part in standardizing not only services across site, but perhaps fees and prices as well?” I'm curious what you think might be happening through healthcare reform or other efforts in that way.

John Toussaint: Well, I think what the methodology does is it's a way for us as providers to adapt to our environment quickly. So, for example, these local corporations here in the market in Wisconsin, and now I'm seeing it in many markets across the country, are saying to health systems, “Listen, we're going to pay you $27,000 for a knee joint replacement. And that's it. And then you have to decide, are you in or not?” And otherwise you're done doing knee joint replacements for this company. And what that's driving is for us to say, “Well, gee, can we actually bundle all of the services for a knee joint and make it as efficient as possible and still make money at $27,000?” So it's really getting the method is to get us back together to say across these, what we call episode treatment groups, like a knee joint replacement, how do we get the services together in the highest quality, most efficient way? And we have to do that or we're simply not going to be in the game.

Mark Graban: And at the summit in June, I forget the speaker's name, the guy who was there from CalPERS in California was talking about this quite a bit where they're basically saying to the health providers, “Here's what we're willing to pay. Are you in or are you out?” Do you see more of that happening around the U.S. do you think in that type of model of the payers, the employers being more demanding, saying, “Look, here's an above-average price. Can you meet it or not?”

John Toussaint: Absolutely. I mean, for elective procedures, I think this is exactly the way it's going to go. “Here's the price.” And guess what? The price isn't going to go up every year, it's probably going to go down. And so you better figure out how to be more and more efficient each year because we're just not going to pay these exorbitant prices anymore. And you know, when you have a variation from, I think it was like $110,000 all the way down to 15 or $12,000 for the same procedure, I mean, what are the employers don't have any choice. They have to basically say, “Here's the reference price” because some of you guys are gouging me.

Mark Graban: Well, and that price variation is shocking when you see that being reported. The quality variation or the lack of correlation between quality and price is pretty shocking. So I would hope if somebody sees that their employer is demanding that they go to an organization that has a lower price, that in a lot of cases that actually implies better quality if not the same. When you see data like that in Wisconsin and other states.

John Toussaint: Right, exactly. The lower the cost of care delivery, the better the quality. And that's just the exact opposite of what most people think in the industry.

Mark Graban: It's very, very counterintuitive. I guess a lot of things are in lean. One other question that came in via Twitter, again, I think this is, these are issues that are really important to healthcare consumers. John Hunter, and John has a lot of history and involvement with the Deming Institute. And he asked to hear your thoughts on healthcare providing prices to customers before they buy, as most other businesses do. Do you see that trend continuing?

John Toussaint: Yeah, I mean, I think this example we just showed or talked about is an example that says, “Here's the price,” and then you decide provider system, you decide whether or not you're going to be a player at that price. And I think that's exactly what's going to happen across almost all elective procedures, everything from heart surgery to toenail removal. I think we're going to see more and more of this, what we call reference pricing, which is, “This is the highest price we're going to pay as an employer and you know, either accept it or you don't get the business.” And I think we're going to see more and more of that. And CMS just came out with a big bundled payment initiative. They just announced it last week. There are a lot of potential flaws in what they've put together so far, so it's going to have to be improved, but they definitely are going down the path of a bundled pricing mechanism for paying providers. So this is the world we live in, which means that we're going to have to get all the players that actually are delivering the service together on the same team to deliver the best service, best quality, lowest cost.

Mark Graban: Well, that's part of the big challenge that's out there for organizations and it's encouraging to see more leaders, more executives, more organizations taking on Lean Healthcare, that opportunity and that challenge to transform the organization. So to maybe wrap up here, is there something really cool that you've seen recently out there under the banner of Lean Healthcare, something that was surprising or a really noteworthy good story that you've seen that you might share with us?

John Toussaint: You know, I was at the South Shore Hospital in Boston a few weeks ago and I observed something that they call “stop the line.” It was a fascinating process where the nurse actually identified a potential medication error or a medication reconciliation error. It didn't matter. She would stop the line by calling this team of a pharmacist and another nurse who would immediately come to her station in front of the patient's room and they would do a root cause analysis on what the medication problem was, whether it was a reconciliation issue or wrong dose or whatever. It took about four minutes. And then the pharmacist and nurse who were part of this “stop the line” team were working with that nurse to identify a solution. I actually observed one of these things happen and it was quite remarkable. You can imagine if you could do a “stop the line” on every single medication error or reconciliation error or anything related to medication problems and actually fix the issue rather than just do a workaround. And that's what they were doing was fixing the issue. That's pretty exciting stuff. So I congratulate them for the work that they're doing and hope to see more of it.

Mark Graban: Yeah, and that's great to hear about. And there are, I think, so many different… if we bring it back to values and principles in a story or a situation like that, the different principles about putting safety and quality first, focusing on the customer, but at the same time supporting the staff and not putting them in a position where they're involved in a systemic error that they might otherwise be blamed for. I mean, that story, I mean, we could probably go on and on about the number of different principles that are embedded into that practice. Would you agree? Are there other principles that I might have missed?

John Toussaint: No, I think that many of the lean principles are embedded in that experiment. And they'd run it on one department, and now they were in the process of spreading it. But again, we've got to build the management system now that can support that daily work. But it was absolutely the right daily work from the standpoint of creating better value to the patient and not passing defects on to the next patient. And I'm seeing things like this now almost everywhere I go in organizations that are really serious about the transformation. So it's a pretty exciting time in healthcare. And I'm optimistic that leaders are willing to change and that we're actually seeing some pretty impressive changes.

Mark Graban: Yeah. And what you described there is something that maybe down the road we can do another podcast. I had meant to take a little bit deeper dive into what you wrote about around model cells and what you described with that “stop the line” process sounds like a model cell. They started in a department, they saw that it worked, and now they're going to try to spread that through the rest of the organization. So maybe would you be willing to come back at some point down the road and maybe talk more about model lines and spreading beyond model lines?

John Toussaint: Yeah, I think that's a whole topic within itself and I think we've learned a lot from many organizations about what is successful related to not only model cell development, but also spread, which has obviously been the most difficult thing of all. So it probably does warrant a whole separate podcast, Mark. I'd be happy to do that.

Mark Graban: Okay. But for now, I'll leave it with the plug. If people would like to read about that, they should definitely check out the book Management on the Mend. It's available through createvalue.org. I saw that the Kindle version is now available on Amazon for just $9.99. So I definitely would recommend people getting the book and giving it a read. I know a lot of people are doing that. And so, John, thank you for the book. Thank you for sharing the good things you're seeing out there and some of the challenges. And thanks for being a guest here on the podcast.

John Toussaint: Thank you, Mark.

Videos with Dr. Toussaint:

Watch a webinar with Dr. Toussaint discussing the transformation model from his book.

A talk John gave in 2009:

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Great interview Mark. Very powerful principles and the accompanying videos are excellent

[…] John’s most recent book is Management on the Mend, which we discussed in episode #225. […]

Comments are closed.