I received a question from a physician I know in Canada and I'll try to address it here (although the answer might not be as definitive as he or his leaders would like). I think the discussion here applies to the U.S. and other countries, not just Canada.

Hear Mark read this post — subscribe to Lean Blog Audio

See previous Reader Question posts. Maybe you have a better answer for this question or others? You can add as a comment to one of the posts, if you like.

If you have a question to submit, please use this contact form.

His question(s):

I'm getting a few wins within my department as a way of showing what disciplined team based problem solving can do. People higher up want to see more. We have lots of problems and some interest – but lack skills and time.

How do I estimate the needs for the department and the hospital to help make a case to show the investment to be serious about improvement:

1. How many lean experts/facilitators will they need globally or per department to build a learning/improvement system?

2. How much time will they need to free up:

A) for a manager or

B) front line workeron a weekly basis to allocate time to improve (not just get stuck doing the daily waste-filled work).

Are there easy answers to these questions? Based on benchmarks? Rules of thumb? I'm not sure.

I've always said, being serious, that you need as many people as you need… and no more and no less. There's no perfect rule of thumb for how many facilitators, no magic answer. It depends on what those facilitators are doing, the type and size of organization, etc. There are many factors involved.

I'd suggest framing and testing a hypothesis about how to determine this number. At a department level, can you get dedicated resources for improvement? This is common in manufacturing (you have engineers, etc. even before possibly having a “Lean person” — I've played these roles in factories before moving to healthcare) but it's pretty rare in healthcare to have “process engineers.” You basically just have people doing the work… and there's lost potential as a result.

Can you add one person to a department and see how that helps? Or, should people be on loan from a central improvement group to help facilitate larger projects and to coach managers on a daily basis?

Or, if executives insist on an absolute knowable number, tell them ThedaCare has 25 to 30 and they should just copy ThedaCare (or shouldn't they?). ThedaCare has had a different number of facilitators over time. Was any of those the right number? The right number for them at that time? The right number for that organization at that time?

What Do Cleveland Clinic Improvement Leaders Say?

The other day, I recorded a podcast conversation with Nate Hurle and Dr. Lisa Yerian about Lean and continuous improvement at the Cleveland Clinic.

Nate said the number of people and resources you need depends partly on the answer to this question:

“How fast do you want to go?”

Lisa agreed with my sentiments expressed here and she, coincidentally, used the same phrase I've used here in my post.

“There's no magic number.”

How Much Time is Needed?

The second is a bit easier to answer, but again there's no magic number. Should managers be spending 30 to 60 minutes each day rounding for improvement? Or more? Daily huddles of 10 minutes are generally not enough time for meaningful improvement. That's barely enough time there to triage ideas with people.

Do you need to give staff permission to work on improvement in a dedicated block or just suggest they take advantage of time as it's available?

When I ask people at my co-author's health system about this, and they've been practicing Kaizen for 10 years… how much time do you spend on improvement? They have no idea because it's so integrated into what they do on a daily basis. They don't track “improvement time” per se.

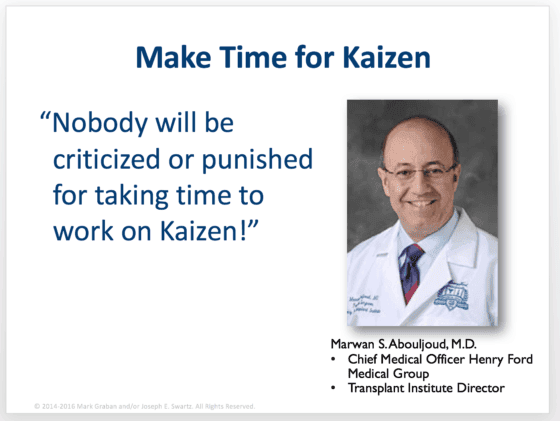

Here's one of their managers talking about making time:

I know one department chief at an organization I coached who told his staff that they wouldn't be punished for taking time away from “real work” for improvement work.

He chose a somewhat arbitrary number of 20 minutes per day (per person) for improvement. But that seemed realistic to him:

I should check in with him… was 20 the right number? I'd hope they'd tweak that number over time in the spirit of Plan-Do-Study-Adjust. If they can't find 20 minutes, how can leaders help? If they free up time through initial small Kaizens, can they now do 30 minutes of improvement each day?

How does that time spent on improvement free up time for them to put more patients into the transplant process? How would freed up time help you and your team?

Nate and Lisa also had some thoughts on this question that I'll leave for that future podcast episode. Subscribe to the podcast so you get notified when it's released (or subscribe to learn about new Lean Blog posts via email).

Does This Help?

I hope that helps… probably not as much as a definitive answer, but I don't think there are definitive answers to questions like these… just experiments to run and things to figure out locally.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Thank you, Mark! I think you are right: no easy answer exist. But there is ultimate goal: everybody, everyday, everywhere. Isn’t it?

Yes, Konstantyn. “Improvement specialists” are just one part of the equation. That might be necessary to get started in building a culture of continuous improvement, having specialists help train and coach others.

But I agree that a further, better state is everybody improving everywhere, every day, as Masaaki Imai says (and some hospitals currently advocate for).

You might be able to get some insight talking to JCAHO parties. It will take longer in healthcare due to regulatory and accreditation attributes, getting top management to view “lean” as part of a means to get to regulatory isomorphism I think will improve the time. I suspect that change will need to start at the interfaces between departments in the internal supply chan and work it’s way upstream. There will definitely be inertia but i expect at a departmental level 10 to 15% of people need be involved devoting a similar amount of their week to that process. So perhaps 1 to 1.5 percent of the entire organization but the process is likely to be sequential so probably less than this amount for the entire organization. Expect a multiple % return on your investment. Continuous improvement should be a standing committee. It probably needs to be chaired by someone charismatic with an outside consultant resident on that committee. Members for that committee should be drawn from departmental “elites” who are sensitive to organization wide issues as well as departmental solo’s . I would to some extent try to pick individuals who have interest in covering relationships with C suite individuals or have an emotional attachment to organization wide recognition.

There is likely a personality test than one might assess prior to selection. Perhaps Strengths finder might help.

Good luck!!

Samuel – thanks for your thoughts.

What do you mean by “Continuous improvement should be a standing committee”? I’m not sure what you mean.

In my experience and what I’ve seen at some leading health systems, continuous improvement is the culture… all leaders, all staff. Not just a committee.

This reminds me of the old adage about meditation – just replace with the word improvement. — “You should sit in meditation for twenty minutes every day — unless you’re too busy. Then you should sit for an hour.”

Thanks, Jeff. I built a blog post around that quote:

https://www.leanblog.org/2017/04/dont-time-meditation-improvement/

I think that there isn’t a magic formula, the important thing is that the worker should have the time to think !! it’s the basis, their workload should be fixed in the right measure.

To the point about basing the number of lean facilitators on “how fast do you want to go”, there are other limits on the pace of change besides the number of lean people. Increasing the number of lean facilitators can increase the number of improvement projects linearly, but probably won’t speed up culture change or transformation, in how people think about and approach improvement, which takes place over a minimum number of years, some say 7 to 10 years. If you only increase the number of projects, your results won’t grow linearly because the supporting culture is just developing.

Good point, Tom. I guess part of the question is how much the culture change is accelerated by more people having more exposure to Lean principles and methods. This often takes place through their initial improvement work, which might be through a Rapid Improvement Event or some other structured Kaizen activity.

John Toussaint and ThedaCare realized that just getting more people into more events wasn’t changing the culture. One of the other variables is the management system and leadership practices throughout the organization.

I don’t think the Cleveland Clinic folks were implying that more people leading or coaching more projects alone is the answer.

The best thing to do is to get Jon Kabat-Zinn’s CD’s on meditation. He has three sets of multiple CD’s as well as one called Mindfulness For Beginners (book plus CD) and another on helping to heal psoriasis. He started his work at Massachusetts General Hospital 30 years ago and his program there is extremely successful, helping people with trauma, mental issues, facing death, etc. He also has some great books on living life. “Wherever you go, there you are” is one. There are several others. There is also a compilation of meditative results at a scientific meeting with hundreds of neuroscientists as well as long time meditation people. It’s called “The Mind’s Own Physician” and includes lots of rock-hard scientific results. The Dalai Lama is also present, talking about living mindfully. Hope this will help people to start a meditative practice using the CD’s, you’ll get better and better but never perfect. Very few are. The ego is a wily beast that thinks it is in charge. It won’t like being put in it place as one of many elements of the psyche presided over by the Spirit. So, you’ll have to be disciplined. One of my great teachers, a mining engineer from South Africa said that “Discipline is that which makes freedom possible.” Think about that.