When I was back at MIT earlier this month, I really enjoyed the lectures that I was able to attend. See my notes from Professor Zeynep Ton's talk on “The Good Jobs Strategy.”

I've heard Professor Steven Spear (not “Spears,” as commonly misspelled) speak a number of times. I love his book The High-Velocity Edge and I've interviewed him before for my podcast in episode 58 (on his book, originally titled Chasing the Rabbit) and episode 87 (on Lean in healthcare).

Steve is always insightful, pithy, and funny.

Update: Here is video of the talk. You can see me on the front row to Steve's left.

Here are a few highlights and key quotes. Not everything in this post is verbatim or paraphrased from Steve. Some of this post includes my own thoughts and reflections, things I'd hope he would agree with.

Steve said:

“Information only has value if it changes your behavior.”

We're often flooded in data, numbers, reports, etc. What matters is changing your behavior in a way that drives improvement. Learning something new and not taking action is something many of us would consider to be pretty useless.

He also asked,

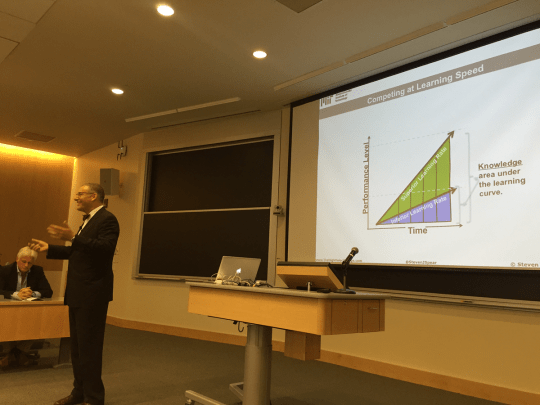

“How do you deliver quality and value to market quickly?”

The answer is a superior rate of learning, as illustrated here:

The diagram says that “knowledge” is the “area under the learning curve.” The faster you learn, the more you learn. The more you learn, the higher your performance.

This, of course, reminds me of The Lean Startup approach of Eric Ries (not “Reis,” as commonly misspelled) that encourages startups to go through as many cycles of “validated learning” as possible, as quickly as possible… learning faster than others.

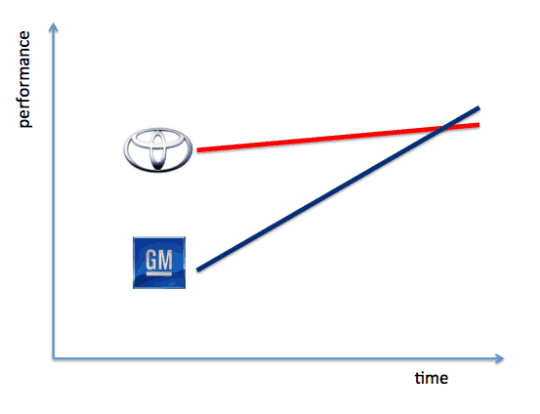

It also reminds me of a diagram drawn by the second GM plant manager I worked under, Larry Spiegel (who got to speak briefly in the great “This American Life” episode on the famed NUMMI plant).

Larry drew a point showing that Toyota was ahead of GM. It looked something like this (without the logos):

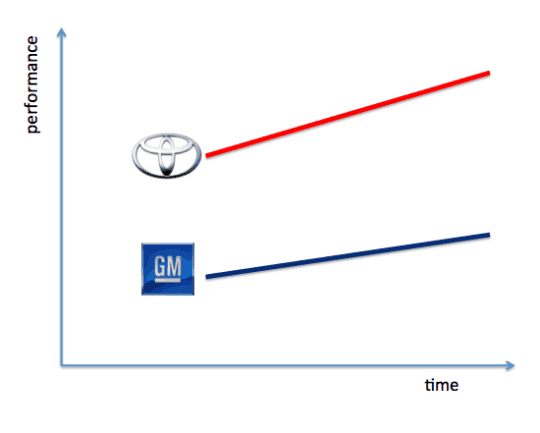

He asked if GM was going to improve more quickly than Toyota was going to continue improving.

If not, the lines would look like this… never intersecting (meaning GM would never catch up)…

Or if GM could improve faster (and maybe catch up eventually):

GM doesn't seem to be on that “catching up” path, even though they have been improving much faster in the last 20 years than they did in the previous 20 years.

Back to Steve Spear, he added:

“The essence of learning is investigating surprises.”

As we improve our work in a scientific method (using PDSA or a similar approach), we should sometimes be surprised by what we find. We should view improvements as something that includes a small test of change instead of trying a “big bang” approach to change where we introduce a change, for example, to every hospital in our system all at once.

As I coach leaders, think about a time an employee has an idea that they think will be an improvement. The only way to know for sure is to test the idea in practice. Sometimes, we'll be surprised that something doesn't work out as planned. The idea might not work, it might not make things better, or it might work but created some side effect.

If we're NEVER surprised, we're probably being too cautious about the changes we are trying.

We might also be surprised when we think something will NOT work. The employee has an idea. The manager thinks the idea won't work. Unless the manager sees how the idea would create a safety risk or some hugely negative effect (such as breaking the law), our bias should be toward letting the employee try the idea. The manager might be surprised that it DOES work.

A few other videos of Steve:

https://www.youtube.com/watch?v=2Odf73AMONE

https://www.youtube.com/watch?v=X4dFcfiGslw

Tweet of the Day:

Easy work:

1 blaming

2 judging

3 imitating

4 pretending

5 waitingHard work:

1 learning

2 teaching

3 inspiring

4 improving

5 giving— Vala Afshar (@ValaAfshar) June 13, 2015

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

I am not sure about “Information only has value if it changes your behavior.” Negative test results often have value and can confirm a course of action you have embarked upon. Or they can tell you to ignore what a symptom that was an outlier and not a harbinger.

I think surprise is the emotion associated with adding a new element to a category and restructuring your mental map. If the change is big enough it may register as confusion.

Both can happen during customer interviews, I blogged about this in http://www.skmurphy.com/blog/2011/11/08/customer-interviews-allow-yourself-to-be-surprised/

“Surprise means you are learning. Or at least an opportunity to learn if you embrace it.”

Good point, Sean. I think you’re absolutely right that some information confirms that you do NOT need to change your behavior.

Thanks for the comment and thanks for reading!

[…] h/t Jason Yip (@jchyip) and Mark Graban “How Do You Deliver Quality and Value to Market Quickly” […]

[…] “How do you deliver quality and value to market quickly?” – Steve Spear at MIT […]