I had a speaking engagement yesterday for a large system, with the audience consisting mainly of hospital CEOs and CFOs. I was able to be around for the entire morning, which included a really outstanding kickoff talk by the system CEO (talking about process improvement as a key strategy) and followed by two internal P.I. people who gave an outstanding talk.

I tweeted some of the highlights and top quotes, which I've collected here in this Storify page.

The Good

Almost 100% of the presentation and comments were spot on.

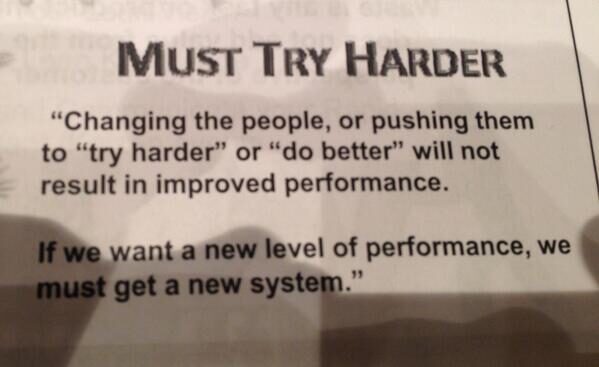

One particular highlight was the emphasis on systems thinking, as evidenced by this slide:

Of course we can't get better performance by just pushing people to try harder, care more, or work harder. We need a new system and Lean gives us frameworks and methods for redesigning systems.

I also really appreciated the presenter's take on the Lean principle of “Pull.” Many people get this backward and they describe pull as “pulling the patient up to the unit when we have a bed available.”

As this system pointed out, pull is really about the CUSTOMER (the patient) pulling on services. The health system should strive to provide these services (like a room and a bed) at the pull of the patient… when the patient needs it, not when it's convenient for us.

The right care at the right place at the right time. That's what Lean is all about.

The Sort of Bad

The only thing I could quibble with was their discussion of waste and “non value added activity.”

They talked about the need to eliminate ALL waste activity (that's the goal, I guess, but a bit of a stretch in reality). We aim to minimize waste.

An example was brought up, basically saying, “Don't freak people out by saying that regulatory requirements, like preparing for a Joint Commission visit, are waste because we have to keep doing those things.”

In any setting, identifying something as waste (not providing value to the customer) doesn't mean we automatically stop doing it. Some waste is required.

For example, we generally consider quality inspections to be a form of waste? Why? Because we'd ideally find a way to mistake proof a process so it's impossible to create a defect. But, until that's happening, inspection might be the next best alternative (it's better to catch defects than to pass them on to the customer).

Toyota, like every automaker, has inspection steps at the end of the line. They strive to “build in” quality as much as they can, with good processes and mistake proofing, but they still do final inspection.

When I worked at a GM engine plant in the mid 1990s, the people designing our factory decided that our Northstar engine was so well designed and was going to be so well built that our assembly line would not have a “hot test” station at the end of the line. The engines would be shipped directly to the car assembly plants, assuming good quality, and the first time the engine would be cranked up would be at the end of car assembly.

The assumption of quality was a VERY BAD assumption. The GM engine plant had some very major quality “spills” where defective engines were caught at the end of the car assembly line. That meant over 1,000 potentially defective engines were upstream in other cars and in our engine plant's finished goods inventory. That's a very expensive problem to fix, whereas a hot test station could have caught the problem much earlier (better yet would have been better process controls that would have prevented the error in the first place).

The Ugly

Let me emphasize that today's “ugly” example is NOT from this health system, but rather from a student paper from a Big Ten university (thankfully, not Northwestern).

From the paper:

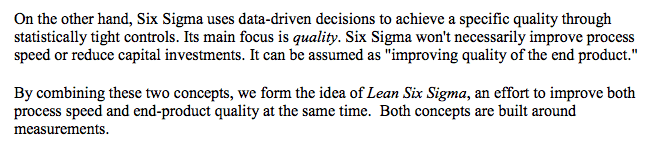

Lean doesn't focus on quality control? Good grief. That's “L.A.M.E.” or Lean As Mistakenly Explained if I've ever heard it.

They fall into the trap of saying Lean is for speed and Six Sigma is for quality. Both methods should produce better flow and better quality. They go hand in hand. The two pillars of the TPS house are, of course, flow and quality at the source (as pictured in this blog post from earlier this week).

I hope the professor wasn't teaching the common, yet incorrect, Lean Sigma fallacy…

I certainly hope the professor corrected them on this when grading the paper… but recently history shows not all professors have a great handle on Lean.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Hopefully he meant “Lean doesn’t solve quality problems it identifies them”. You could lean a system hitting all seven areas of waste and never improve quality. Remember identifying defects doesn’t cure them. Typically there is enough low hanging fruit at the onset to make most novice managers claim victory and move on. Linkage and flow is what you want, speed and quality will result if you never claim victory but continuously improve.

Well, from reading the whole paper… it was pretty bad on many levels.

They talked about “Lean Sigma” but then the entire paper was about Lean. The section on what “Six Sigma tools” they used was really just a restatement of their analysis in the DMAIC framework.

So, they should have just called what they were doing “Lean” and certainly should have realized that Lean is about about quality and flow. And, like you said, it’s about identifying AND solving problems.