While I'm in Japan this week (read about the trip), I'm going to keep my blogging light – my aim is to share one picture or thought each day.

The tour starts on Monday with a visit to a Toyota assembly plant.

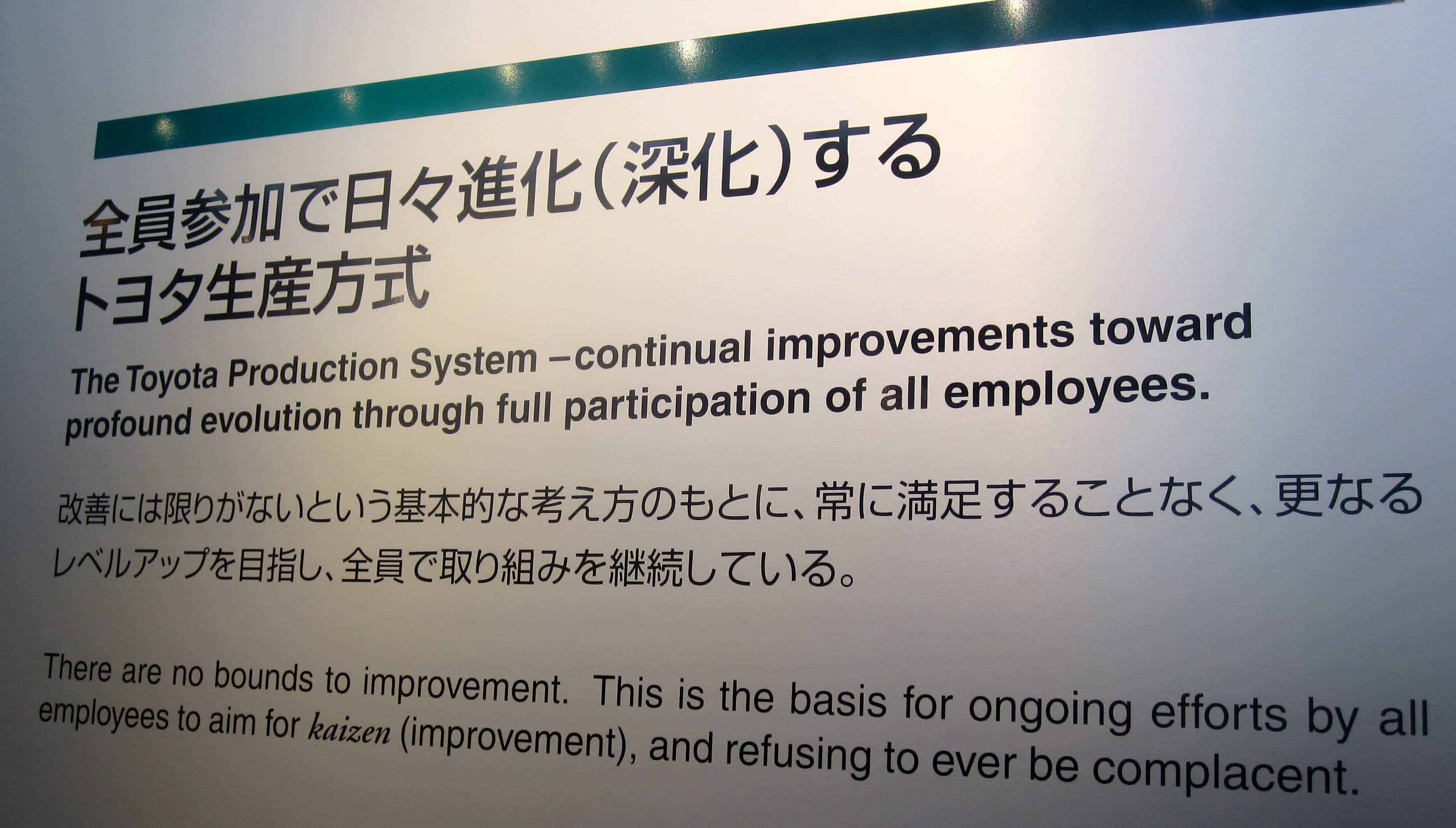

On Sunday, I went to the Toyota Museum. There was quite a large exhibit about the Toyota Production System. There were a few signs that had slightly different definitions of TPS. One, in particular, said:

Other signs talked about the dual pillars of “jidoka” (automation with a human touch, for quality) and “just in time” production.

But I like how this sign focused on kaizen and continual improvements.

“There are no bounds to improvement.”

“Full participation of all employees.”

“…refusing to ever be complacent.”

That's powerful. That spirit is much harder to copy than isolated Lean tools. That's what makes TPS so meaningful.

The exhibit had many examples of employee Kaizen efforts from the factories.

An early Toyota motto, as emphasized on the tour was “Always be studious and creative, striving to stay ahead of the times.”

TPS Overview Video

2022 Update: At least at the moment, the Toyota Production System overview video, as shown at the museum, is on YouTube:

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.

Good Luck in Japan. Please asked and post information regarding their performance review system. Wondering if any ah ha’s are to be found.

I read an article not long ago about Dr. Deming yelling (sort of) at the Japanese in about 1990, chastising them for adopting American-style performance review systems and such. I’ll try to ask if that’s still the case.

[…] I was able to visit Toyota City as part of the Kaizen Institute tour I am a part of. Now, we weren’t able to take pictures in the Takaota factory that we visited […]

[…] San Antonio, here are some pictures from the visitor center… You can compare this to what was displayed at the Toyota Museum in Nagoya, Japan and two pictures (in this post) from the visitor center of a Toyota plant in […]

Comments are closed.