During my recent visit to Franciscan St. Francis Health System, some of the nurses proudly called themselves “Kaizen Queens” (and there was one self-described “Kaizen Princess”) although they also use the term “Kaizeneer” that Franciscan uses more broadly.

During my recent visit to Franciscan St. Francis Health System, some of the nurses proudly called themselves “Kaizen Queens” (and there was one self-described “Kaizen Princess”) although they also use the term “Kaizeneer” that Franciscan uses more broadly.

In the endoscopy department, they have implemented more than 750 improvements in the past four years (in a team of 30 people). That sets the bar really high for the rest of the Franciscan system and for healthcare organizations everywhere.

One of the Kaizen Queens wore a badge holder that proudly proclaimed that she had implemented more than 200 Kaizens. This means she either initiated the process or was part of a team – they share credit, recognition, and rewards quite freely.

One of the Kaizen Queens wore a badge holder that proudly proclaimed that she had implemented more than 200 Kaizens. This means she either initiated the process or was part of a team – they share credit, recognition, and rewards quite freely.

One of her colleagues described a Kaizen where the first identified a problem – patients who needed a scope down their throat for a certain test were asked to swallow a thick, viscous lubricant that was purchased from the scope manufacturer. The patients hated the goop – the taste and the texture (as if having a scope down your throat isn't bad enough). She said it was like, sorry, “flavored snot.”

The nurse had an idea one day – would applesauce work to replace the lubricant? The five-step process used (and described in our books) does not include rushing to test an idea.

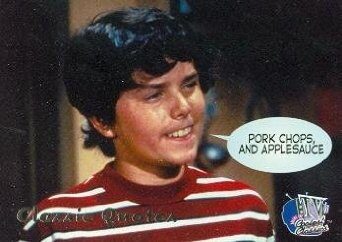

That makes me think of Peter Brady and The Brady Bunch.

The Kaizen process is:

- Find ideas

- Discuss them

- Implement (test) them

- Document them

- Share them

The nurse talked with her colleagues and the manager. She reached out to the scope maker to see if applesauce would cause any problems. Everybody gave a thumbs up to trying the applesauce.

A common theme across the departments we visited was that managers rarely say no to ideas. Saying no discourages people. Possible improvements are proven out (or disproven) through testing and practice (following the PDSA cycle of Plan, Do, Study, Adjust). Managers do occasionally say “no” if an idea would violate regulations or other guidelines. But, they then work together to find a different idea that would solve their problem.

In this case, the use of applesauce was indeed an improvement. Like most Kaizens, it was a win/win/win/win – using applesauce saves the hospital $30,000 a year, it's preferred by the patients, it creates a less frustrating environment for the staff, and it doesn't negatively impact the quality of the scope testing.

The Kaizeneers documented and shared the idea. Imagine if that idea could be shared more broadly throughout our nation's healthcare system (or beyond). We don't have many mechanisms out there for sharing ideas. We do have forums like the Healthcare Value Network or AHRQ, or technologies like KaiNexus (which allows users to selectively publish ideas to be seen by users at other organizations). By the way, if you have a Kaizen you'd like to share with others, you can do that through our book's website.

In many hospitals, there would have been a laundry list of reasons for a manager to say no to the idea. “Just use the standard lubricant.” “Oh, patients don't hate it that much.” “Why can't you just follow the standard work?” “We'll have our quality committee discuss that.” Leaders who say things like that stifle improvement and innovation and damage morale.

I asked one of the endoscopy nurses what would happen if she, for some reason, ended up in a workplace without a manager who encouraged and supported Kaizen. She said she would probably try to push Kaizen and bring ideas forward for a while (thanks to her intrinsic motivation). But, if the manager wasn't into it, she'd probably just stop trying.

There are so many more stories from that day. I'm going to write more blog posts and Joe and I plan on sharing video and audio from the interviews in different ways. Stay tuned.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: