You might remember that I partnered with Kaizen Institute about two years ago to do their first “Lean Healthcare Study Tour” to Japan. I blogged a bit about the last trip last week.

You might remember that I partnered with Kaizen Institute about two years ago to do their first “Lean Healthcare Study Tour” to Japan. I blogged a bit about the last trip last week.

It was a great learning experience, as a group of healthcare leaders and Lean practitioners from around the world spent a week with a deep dive into Lean culture (and Japanese culture, which are not always the same thing).

We visited Toyota, another great manufacturing facility, two hospitals, and other sites.

We had amazing discussions amongst the attendees, including participants from North America and across Europe.

Everything was organized for us, taken care of and led brilliantly by bi-lingual guides who know Japan and Lean. If it's your first visit, having this sort of expert guidance is very helpful.

There were MANY valuable lessons and ideas to bring home and to put into practice when we got home.

This year, I'm told that Kaizen Institute has new tour sites lined up, which I'm assuming (and will confirm) again includes Toyota and, this time, some new organizations and tours.

The trip is scheduled for the week of November 17, 2014. We are still working out details, but since this would be my second trip, the idea is that I'll play more of a co-facilitation role (helping people understand the factories and lead the Lean discussions), while other Kaizen Institute staff from Japan will play a huge (and important role) with logistics, translation, etc.

If you're the least bit interested in participating and would like to learn more details, please contact me or visit www.JapanLeanTrip.com.

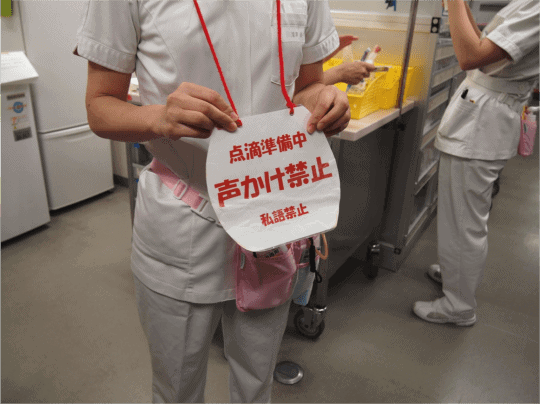

A picture from our last tour… a nurse with her supply bag (a product of 5S) around her waste waist and a “do not disturb” sign for medication rounds (a form of error proofing).

Some of my blog posts about the 2012 trip:

A Japanese Hospital CEO on Kaizen, Innovation & Breakthrough

Japan Tour Reflections: Taking Home Lean Artifacts or Lean Thinking?

Japan Trip: Going to Gemba and Seeing 5S at a Japanese Hospital

A Small Batch of Bread, Other Random Japan Pictures

I hope you'll join us.

To learn more about the trip, please contact me.

Tweet of the Day:

Dilbert's "Jeff" would not be a good #Kaizen coach or leader http://t.co/zW3iNEeNNq

— Mark Graban (@MarkGraban) June 19, 2014

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Right above the picture of the nurse you have the following text…

I know you have waste on the brain as a Lean consultant, but this one should be waist.

How is the sign supposed to help error proof the medication rounds? I can see that other employees would recognize the need to leave a nurse with the sign on alone to complete their rounds, but patients might not understand and interupt them.

Thanks for pulling the andon cord and pointing out the defect, Chris. I wish I could blame auto-correct, but that wouldn’t be true and blaming isn’t a Lean behavior anyway.

The signs are not the best form of error proofing possible. The signs are intended to create an “interruption-free zone” where interruptions and distractions are at least minimized. Generally, the interruptions would come doctors or other nurses out in the unit… I don’t think the sign is something that should be worn into patient rooms… patient needs come first. If they have an urgent need, they shouldn’t be afraid to “interrupt.”

Here is a nice blog post from Virginia Mason Medical Center about traveling to Japan:

Lessons from Japan: Value of deep dive into TPS

It’s also great to hear that VMMC is incredibly transparent when people from other health systems are around:

Great to see.

Good news is that this trip is definitely ON.

We have 12 people formally registered so far an a few spots left.

So, look forward to blog posts about the trip in November and beyond.