tl;dr: In this post, Mark explores Toyota's principle of “Respect for People” within the context of Lean methodologies. He delves into how this principle is deeply integrated into Toyota's culture and operational practices. Through various examples and insights, Mark emphasizes that “Respect for People” is not merely an abstract concept but a practical approach that fosters continuous improvement, employee engagement, and organizational excellence.

A principle that has been often discussed (and hopefully practiced) in the Lean community over the past few years is usually described as “respect for people.”

A certain British

Let me explain why he's wrong — “respect for people” is not

Hear Mark read this post — subscribe to Lean Blog Audio

When I was first taught about Lean and the Toyota Production System in the mid 90s, the focus was on tools (heijunka boards, kanban cards, 5S) and a few cultural elements (engage people in improvement, be in the “gemba”) – but the phrase “respect for people” was not explicitly taught.

That phrase has only become widely discussed in the past five years or so, but it's not a recent invention – nor is it just a Western interpretation of Toyota's approach.

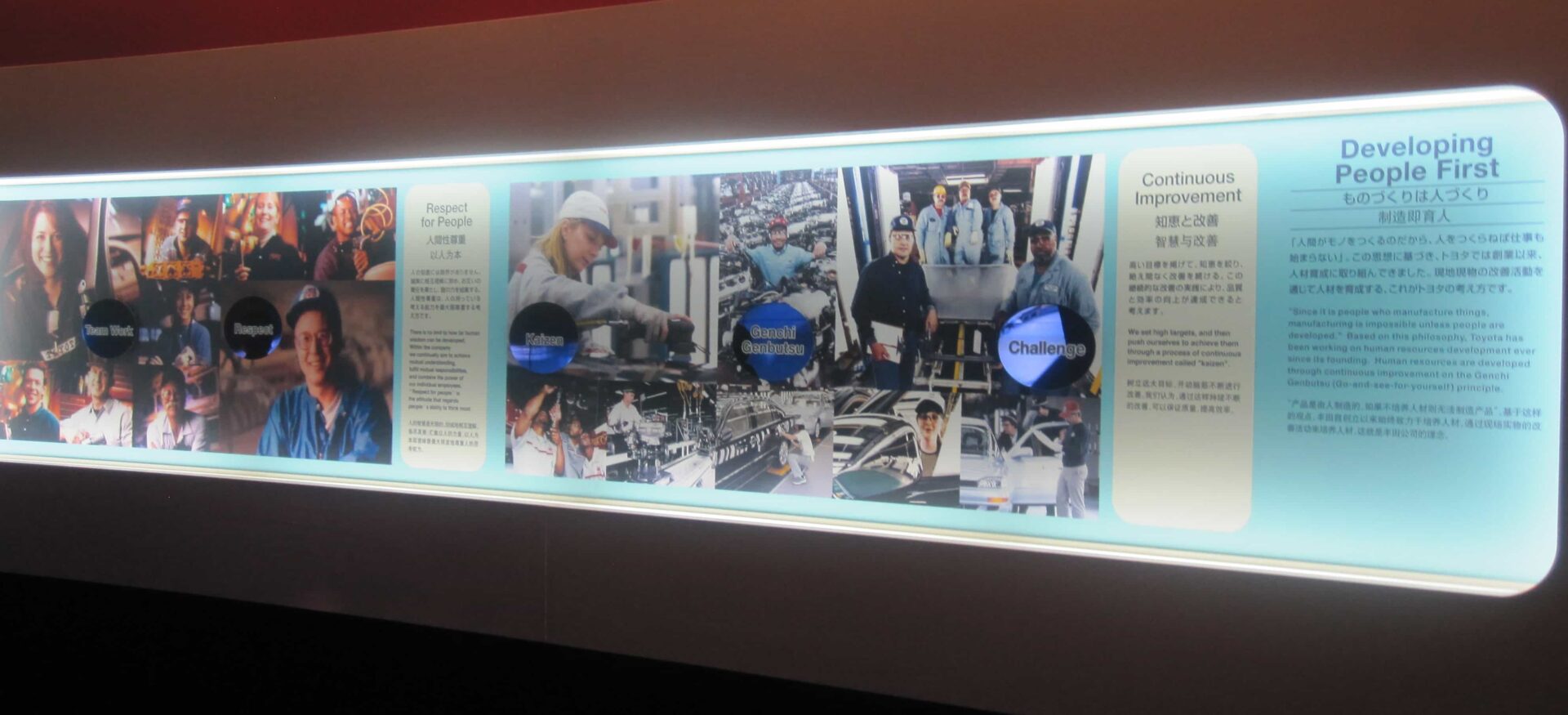

When I visited a Toyota plant in Japan last November, the term “respect for people” was highlighted for visitors. At the museum, you saw this display (large and prominent):

The two parts of “Developing People First” are “Respect for People” and “Continuous Improvement.” These are often referred to as the two pillars of The Toyota Way management system (and I've seen them referred to as the “equally important pillars” by Toyota's legendary Taiichi Ohno – see page xiii of the book).

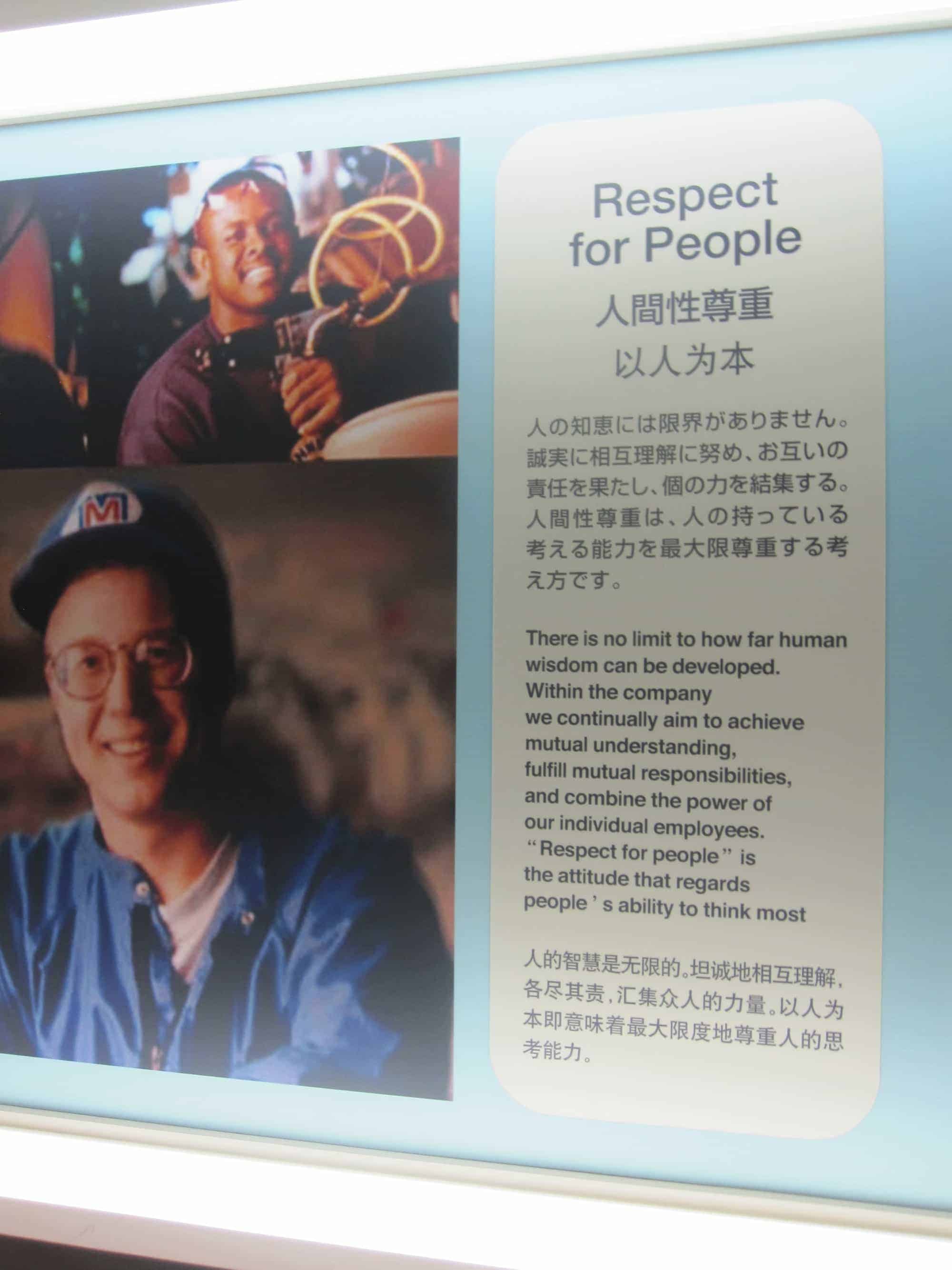

Here's a closer look at “respect for people” in the Toyota display:

The saucy Brit said that “respect for people” was a “consequence” of doing excellent work and that it, basically, isn't something you could focus on in and of itself.

The Toyota sign above says:

“respect for people is the attitude that regards people's ability to think most.”

Does that sound like horse sh*t or a Western interpretation? It certainly appears that Toyota focuses on the attitude and behaviors as a fairly prominent goal of TPS.

Respect is not about being nice, nor is it about having great “people skills.” It's about challenging people to perform to their peak ability, not being superficially nice.

Some perspectives and other reading on “respect for people”:

A great post by Kaizen Institute's Jon Miller: “Exploring the “Respect for People” Principle of the Toyota Way.”

Jon also goes back to some source Toyota documents to explore this idea and the difference in wording between “valuing” and “respecting” people, as well as the difference between saying “people” and “humanity” or “humanness.”

Jim Womack of the Lean Enterprise Institute wrote an e-Letter about five years ago that does a great job of comparing how Western companies normally view “respect” versus the Lean view.

Mike Rother explores this idea, including being “challenging” as a way of showing respect in his post:

In studying Toyota I often got the impression that respect for people means that it's disrespectful of people to not utilize their human capability to learn and to grow.

Of course, author and professor Bob Emiliani deserves a lot of credit for highlighting “respect for people” consistently in his writing:

Toyota does not use one simple, discrete definition to express the “Respect for People” principle, whose context is better represented by the phrase “Respect for Stakeholders”. Rather, it is a more elaborate multi-layered description that includes historical words from former Toyota executives to better comprehend its meaning. Toyota's top-level representation of the “Respect for People” principle consists of two parts: “Respect” and “Teamwork,” and is as follows:

“RESPECT: We respect others, make every effort to understand each other, take responsibility and do our best to build mutual trust.

TEAMWORK: We stimulate personal and professional growth, share the opportunities of development and maximize individual and team performance.”

Author Natalie Sayer (Lean for Dummies) had an excellent guest post here on my site, Respect for People Goes in All Directions.

“We as individuals will contribute to a culture of ‘Respect for People' just by how we show up in each moment. It starts with self-awareness and personal accountability for our own leadership. Ask yourself, ‘Am I:

* continuing to grow, learn, and develop?

Natalie Sayer

* building capability with those around me?

* coaching and acknowledging others?

* using language constructively, listening and communicating effectively?

* contributing to the development of a Lean culture?

* actively improving processes and solving problems?

* being accountable to the results, as well as, the process to achieve them?…”

And Art Smalley does a nice job of explaining the history that shows “respect for people” is not a recent invention and some of the first and foremost ways of showing respect including having a safe work environment.

“About a decade ago Toyota simplified its philosophy down to the two pillars mentioned – continuous improvement and respect for people. It is true that you won't find much written about “respect for people” but that is not to say that Toyota does not emphasize the concept in some obvious ways. The roots for the concept inside Toyota at least date back to Sakichi Toyoda's founding precepts in the 1930s or earlier depending upon the version.”

You can read Jeff Liker's books on Toyota, where respect for people is a core theme and he also had this blog post:

“In fact, within Toyota they say respect for people is the foundation for continuous improvement. And a key component of respect for people is investing in them, in training, job security, and their morale. It is very important to understand that the concept of making investments does not disappear with lean.”

@SeanStickle writes this on his blog, referencing the philosopher Kant:

“Respect for people does not mean that we must like the people we work with, or get along with them, or even think they are good people. It means that we understand that they are moral peers, not merely instruments suited for some business purpose.”

I've really come to appreciate how “respect for people” and “continuous improvement” (or Kaizen) are intertwined. We practice CI because we have RFP… we practice RFP by engaging people in CI and by challenging them to perform better… for the sake of our customers and our patients (for whom we also have respect).

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![Gemba Claus is Comin’ to Town! [An Original Song]](https://www.leanblog.org/wp-content/uploads/2023/12/gemba-claus-lean-blog.jpg)

Comments from LinkedIn:

Jim Haugen: Great post Mark – A big Respect challenge in healthcare is getting doctors to accept and expect – even demand – that they be challenged by their support staff. Challenging the doctor when a nurse, PA or even another doctor has a question, doubt or concern should be viewed as a show of ultimate respect – respecting the doctor’s knowledge, experience and maturity enough to know that the doctor understands that she/he is not infallible, and that they have learned from their work with the doctor that the patient is always the first concern

John W. Kennedy, Ph.D.: Great stuff, Mark, as people make things go, and respect is a key to all things in life. I am glad to read this about Toyota, as earlier trips I made to Japan on business did not support this view. Change is good, and positive change is great. JK

Yes, Jim — doctors and surgeons should respect their support staff. When staff want to speak up, they are showing respect for their patients… and MDs have to help create an environment where everybody is respected for the role they play, regardless of their education level and the letters after their name (or lack thereof). This is a key point from “Crew Resource Management,” as adapted from aviation into healthcare.

Ha, “a certain British rabble rouser”… Well who would that be (knowing past discussions) ;-)

Thanks for this good post and all the good quotes to illustrate the concept.

Despite my disagreement with some of the rabble rouser writings and definitely also the way he puts thing forward, I do agree with one point: I also don’t think standalone programs make sense. Still, more and more often I notice, Lean is attempted primarily as a leadership and a formalized (thru methods), bottom-up continual improvement effort without much attention for the strong industrial engineering roots it also has.

Furthermore, I think Lean culture is so intertwined with its methods and techniques that they tend to reinforce eachother both ways. For me, Lean has always been a lot better at developing concrete leadership behavior than all (in- and external) leadership trainings I particpated in. And I think it is primarily due to its strong interconnection with “standardized” rituals, specific language and symbols that are also part of a strong Lean culture. I have also written abut this problem of separating “hard” and “soft” aspects in a previous post: http://www.dumontis.com/en/lean-culture

Another thing I always notice about the theme “respect” is that it is always used in relation to the company’s associates.

In my past experience working for and with Lean companies, “respect” also related to many other elements. Think about respect for (internal) clients and suppliers, respect for the company’s standards, respect for products (think about how we store and handle them after we’ve put them together with much care), etc. For me “respect” goes a lot further than just respecting people (see also: http://www.dumontis.com/en/blog/lean-organization-respect).

Kind regards, Rob

Thanks, Rob.

Toyota also defines “respect” very broadly – to suppliers, customers, community, environment, etc.

” Respect ” is very unique and very precious word while observing how it works. It is not simply a word, its a way of thinking…way of looking at the situation. It is one of the most important pillar of The Toyota Way and Continuous Improvement ( by jeffrey K Liker ) It also explains about Lean Leadership, Developing Lean Leader, Spreading Learning and Accelerate Lean Transformation but RESPECT is the pillar of all these ..Take anything as an example, with respect it becomes more EASY, FRIENDLY, ILLUSTRATIVE, APPROACHABLE, PRODUCTIVE, QUALITY & MEANINGFUL!

Good article

RP has always been important in the history of progressive management because it is what enables CI. Without RP, CI fall flat or quickly dies, and you get Fake Lean/LAME. The two principles are connected http://www.bobemiliani.com/oddsnends/cirp_matrix.pdf

The major distinguishing features between progressive management and traditional management is the use of the scientific method and the RP principle. To ignore RP is to not be fact-based; a nutter as it were.

I gave a presentation about RP in 2007 and was followed by the tosser Brit in question who, immediately upon taking the podium – the very first thing he did – was criticize my presentation as codswallop. Such brazen willy-waving!

I don’t know what motivates this type of narrow mindedness and willful desire to ignore history. Perhaps it does not serve one’s needs, or simply a perpetual ring-sting. Regardless, we have had to deal with nobbers, pillocks, and ruffians in the past will certainly have to do so in the future.

1920s British flow production pioneer Frank Woollard characterised the RP principle in his day as “Benefit for All,” and has this to say about it: “This principle of ‘benefit for all’ is not based on altruistic ideals – much as these are to be admired – but upon the hard facts of business efficiency.”

The brave people who have actually achieved flow in practice know this.

Thanks, Bob. I especially appreciate the Wollard quote. When you look at Toyota’s practices – developing people, engaging them, not laying them off when sales drop – I don’t think they are being altruistic or charitable. They are just making good long-term decisions for the long-term sake of their business. Smart.

Great post, Mark. In concrete terms, I have found disrespect easier to explain than respect.

For example, giving a person a job that requires doing nothing 50% of the time is saying “your time is worthless,” and therefore “you are worthless.” Many managers do not realize how disrespectful this attitude is, particularly where labor is cheap.

Ignoring complaints about minor safety issues, like sharp edges on a cart, is also showing disrespect.

There are many such aspects that are prerequisites to asking people to participate in improvement and contribute ideas.

The Frank Woollard quote in Bob Emiliani’s comment explains why you should pay respect to your people. It’s not about being nice. In the long run, you cannot compete unless your organization fires on all intellectual cylinders.

[…] See on http://www.leanblog.org […]

One additional thought… I *do* believe that choosing to respect people and treat people more respectfully can be a choice (or an “intervention” if you will) for an organization.

This probably isn’t easy. Leaders need to understand what behaviors and mindsets are DIS-respectful (ala Michel’s point).. what are the underlying assumptions behind those behaviors? What mindsets do we need and what behaviors will demonstrate those?

What you think becomes what you do.

What you do becomes who you are.

I believe people can change. They have to want to change. They have to see a gap between their current level of respect and a more respectful state.

But, I wholly agree doing nothing but increasing “respect for people” is not a replacement for kaizen and wholesale system redesign as we often see in the Lean world.

Even incorporating RFP with just the use of “lean tools” would be better than just using a tool… even if that’s not as good as more systematic approaches.

But, again, I see people incorporate RFP into Lean more than I’ve ever seen people somehow just focusing on “respect”. The Brit in question was creating (as he tends to do) a straw man argument… talking about something that hardly any body does as a way of somehow indicting the whole Lean community (which he has distanced himself from).

To Michel Baudin’s point…

Our friend unfortunately possesses a low-grade understanding of the Lean management system. He does not understand it as a solution for information flow problems. If he did, the requirement for the RP principle would be self-evident.

For example, it took Woollard 2 years to achieve flow in the engine shop, but it took Ohno 5 years do the same. Could having poor people skills, as Ohno was well known to have (and Woollard not), contribute to that outcome? What our friend ignores, as most people do, is TIME.

Great post and great comments. But why is it even being discussed? Morons can say anything they like. Is there, has there ever been, a doubt that people do the job? and that respecting them will result in a better job?

Even if we forget the people and talk of machines, cells, plants, whatever you can think of that has been put to work. If you don’t respect them (oil the engine, water the plant, feed the cells the right stuff…give them what THEY need, not what you think they should have) the job will not be done or not done right.

Mark is right. It is not about being nice (although being nice is a nice way of doing it), it is about understanding what can help people improve, thrive, feel good about going to work and feel proud for their achievements.

Show me one successful company that declares they don’t care about their people…

I would be careful about calling anybody a “moron.” There’s a difference between a “lack of understanding” (as Bob E. put it) and being dumb.

Great points otherwise.

I think nearly every company CLAIMS employees are their greatest asset and they talk the happy talk… but the walk doesn’t match the talk. Lots of failed companies claim (often laughably) that they respect and care about their people.

That’s why companies like that are so noteworthy and so rare… Southwest Airlines, In N Out Burger, Nick’s Pizza & Pub, Zingerman’s… links on Nick’s and Zingerman’s:

Podcast with Nick

Blog post about Zingerman’s

Leaders who demonstrate their respect and caring through the development of their employees get my highest respect.

“Respect for People” is a great short hand statement. There is a great deal of complexity packed into those words, as the links above show. The details discussed in those quotes and links, and more, are necessary to have a decent appreciation for “respect for people” in the lean context.

At the simplest level respect for people requires systems that are designed with people in mind – systems are not designed as though robots were doing what people did. Then those systems also must be built in a way that respects the inherent value of people.

And the idea builds beyond that and grows into an understanding that in order for human systems to be most effective they must engage people. There are significant limits to how effective systems with people can be if you act as though people are just robots to implement the instructions given by some boss. Respect for people moves from being about just the inherent value of people themselves to a principle to allow organizations to be most effective.

Within these principles are all sorts of shades of grey where the principles shed light on ideas to consider but it becomes challenging to know what the specific situation calls for.

Things also get complicated with the way English works. There is another aspect to respect that has to do with having confidence in someone’s ability or maturity.

You don’t show more “respect for people” by overestimating them. If someone does not have the statistical skills to do a task it isn’t a failure of “respect for people” to acknowledge that.

I find myself making decisions on how to treat people differently based on what can be seen as different “respect” (in the respect = confidence in their capabilities and their self-confidence). With some people I can simple say, no you are wrong in this case it is best to do x, y, z. I find this is what I can do with those I have the most of the “respect” for.

For people that have a tendency to take things personally instead of simply understanding we are debating an idea if my statement is wrong and you disagree with me that isn’t a sign of disrespect it is just a disagreement.

I think there is often a misunderstanding by some that think “respect for people” means not making anyone uncomfortable, which is a flawed view, in my opinion. They sometimes view being challenged as not “respecting their view.”

I discuss various aspects of respect for people on my blog frequently http://management.curiouscatblog.net/tag/respect-for-people/

I meant no offense. I do not know the gentleman who made the statement and could not make a judgement. What I meant to say was “people say things to draw attention”. I was probably carried away…

Enjoyed the blog and comments Mark, thanks. Liker’s and Rother’s lines struck home-challenging and training.

It seems the presentation of ‘Lean’ often goes first, concretely, to elimination of waste (or continuous improvement) because it may be easier to explain, measure, and define ROI. The 8 wastes are specific.

Respect is less tangible, certainly the other tandem key. Respect has to be deeply embedded into that CI foundation. Respect of the customer, respect for the work, self-respect & respect to those doing the work. Gaps in any of those four and over the long term you lose.

Doc – thanks for your comment. You’re right that leaders usually get excited about “waste reduction” because they then think “cost reduction” and ROI. There’s so much more to continuous improvement than cost cutting, of course.

On respect, I had a chance to tour the Toyota plant in my new hometown of San Antonio. In the visitor center, the VERY FIRST WORDS you see are “Respect for People.”

It says, “Respect for people and the need to modernize inspires continuous improvement.”

Respect for people leads to continuous improvement which leads to benefits, including safety, quality, and cost.

“Respect” isn’t just a consequence. To use our British friend’s example, Taiichi Ohno didn’t have great people skills but people respected him because he did brilliant work. OK, fair enough. But, arguable, Ohno pushed people to improve because he respected them and acted accordingly to help them get the most out of their abilities… he maybe didn’t do it in a way we would have done (he was nicknamed “Mr. Oh No!” for a reason).

Respect is a principle can can take action on… it’s not just a result, it’s a principle that leads to our action each and every day. The Toyota tour guide (a production associate) talked a lot about the “voice of the team member” and how that was listened to so often and how it led to so many great improvements. That’s exactly the “intervention” (to use the Brit’s word) that so many organizations need.

I was an presentation at a 1997 SAE conference in Long Beach when a young Toyota Engineer defined one of the four principles of Lean being respect for humanity which includes customer, employees, and suppliers. So the term has been floating around for a while at least internal to Toyota.

The display at the Toyota plant in San Antonio at least implies “respect for people” goes back to Sakichi Toyoda, the founder of the loom works that preceded Toyota Motor.

The reason respect for employees is so critical is that without it there is no inclination to develop people and without this desire there is no inclination for self-learning by leaders, no effort to go to Gemba, and a blame the tools that work for me mentality. Opposite of respect is the “hold them accountable” mentality which cannot exist in a Lean transition for the reasons mentioned. A key behavior of a leader’s ability to lead Lean is how much personal time is spent developing subordinates compared to holding them accountable. If your leader isn’t spending time developing subordinates after establishing the need to do so in a Lean transition then it is probably game over.

I wonder how many organizations measure that on an annual basis – the amount of time leaders are developing people. If not the amount of time, is the result or impact of this measured in some way or at least gauged in a qualitative way?

The Western business bias is toward grading managers on their RESULTS, not their process. We need to focus on both, I think.

Interesting comment. I have always seen this balance between the “what” (ambitions on outcome indicators or control items to follow up) and the “how” (initiatives to deploy/improve standards with check items to follow up) one of the key elements in hoshin kanri.

In a recent presentation by Roger Gerard (ThedaCare) he said one of his big regrets was not doing a readiness assessment, or something like that, when ThedaCare started on Lean. The assessment would have to be behavioral based as no senior leader would say they don’t develop people. I’ve been mulling around in my mind what such an assessment would look like. I have a few thoughts. It might make an interest topic.

I’m going to see Roger present at the Society for Health Systems conference Saturday in New Orleans. I will ask him about this and “respect for people” as a conscious mindset and action for leaders at ThedaCare.

Such an assessment WOULD be very interesting…

[…] Toyota, Respect for People (or “Humanity”) and Lean by Mark Graban – “I’ve really come to appreciate how ‘respect for people’ and ‘continuous improvement’ (or Kaizen) are intertwined. We practice CI because we have RFP… we practice RFP by engaging people in CI and challenging them to perform better… for the sake of our customers and our patients (who we have respect for).” […]

[…] Respect for Everyone – Toyota, Respect for People (or “Humanity”) and Lean – Long Term Thinking with Respect for People – Respect People by Creating a Climate for […]

[…] being eliminated, one of the two pillars of Lean and the Toyota Production System is “respect for people.” This doesn’t necessarily mean always being nice and kind when dealing with others, […]

[…] Virginia Mason understands that “respect for people” is a core part of this philosophy (as I’ve recently blogged about). Respectful behavior is an active choice we make each and every day. Disrespectful attitudes and […]

[…] seen a company have a respect-for-people project, and I never have either. In his comments on Graban’s post, Rob van Stekelenborg writes “Still, more and more often I notice, Lean is attempted […]

After reading the article and the comments, I’m struck by

the connection between self-respect and having respect for others.

One goes in hand with the other. This comment really stood out for

me, “A key behavior of a leader’s ability to lead Lean is how much

personal time is spent developing subordinates compared to holding

them accountable.” One is warm, working with others to help them

improve and the other is cold, holding them accountable. This feels

like being kept at a distance, removed from and separate. That

doesn’t mean that people shouldn’t be held to high standards. I

prefer warmer relationships. I will grow and get better. Cold

relationships make it really difficult to move forward. My respect

goes to warm connections, not cold ones.

[…] Respect for people comes into play through trust and communication with partners up and down the supply/service chain in order to define and create that customer value. It’s not just about “being nice” or philanthropy. It actually has hard and fast applications to optimizing operations. […]

[…] What Is Respect for People? by Chad Walters. “Respect for people comes into play through trust and communication with partners up and down the supply/service chain […]

[…] One of the pillars of the LEAN school of quality management is “Respect for People” (Mark Graban at LeanBlog just did a great article about it here – Go read it! It’s worth taking 5 minutes to hear what he has to say about building […]

[…] Isn’t that beautiful? We’re humans, we fail and make mistakes all the time. And that’s okay. We also have the ability to be kind, to learn and to work together to accomplish greatness. In its creators minds’ the saying also contained the imperative to invest in people as well as…: […]

[…] and the Toyota Production System are grounded in a foundation of “Respect for People.” What Vox describes seems pretty ruthless and more like GM and Chrysler of the early 2000s, […]

[…] Respecting people (see more) […]

[…] One of the two main pillars of the Toyota Way management system is “respect for people.” I’ve blogged about that often over the past ten years, including this post. […]

[…] to see that a patient can feel bad for people working in a bad system. The Lean notion of “Respect for People” means, in […]

[…] Leaders and managers (including the Lean Manager?) were disparaging the employees? Where was the “Respect for people?” […]

[…] don’t see people operating that way. Does such behavior rank really high in the “respect for people” scale? Is that the right way to engage people in […]

When we started capturing the “Lean Enablers for Systems Engineering”(Shingo Award) and the best practices for systems engineers and program management (collaboration with MIT, PMI, INCOSE and industry) to achieve the best product/program possible for the customer, Respect for People landed as a most important success factor. Value, Value Stream, Flow, Pull and Perfection were traditional key Lean enablers. Respect for People was stated as foundational for the team.

[…] two major pillars of the Toyota way are interrelated in a very interesting way. As Mark Graban from leanblog.org describes it: “We practice continuous improvement because we have respect for people… we […]

Great article, and I have another reference for you. It’s a quote from Art Smalley in his December 2005 article TPS vs. Lean and the Law of Unintended Consequences”, published in Superfactory.

“Everyone managing people at Toyota is expected to not only have knowledge and proficiency of their job, but to teach, improve, and solve work team related issues in a standard and expedient manner, as well. ”

I believe this is at the heart of Respect for Humanity. Continuous development of every person, fully embedded into the supervisor relationship and daily work. In contrast, many companies still treat personal and professional development as an “extra”.

Thanks, Mike. Here is a link to Art’s article (PDF).

Too many managers in healthcare (and I’m sure other industries) are not taught how to teach, train, improve, solve problems, etc.

It’s OK if they aren’t born with that skill. I think Toyota and others have proven that you can DEVELOP those skills (learning and practicing with a coach).

Doing so it not just respectful to the employees, it’s also respectful of managers… setting everyone up to succeed.

Hi Mark, love the post. I feel as though it is very important to talk about respect for people because i believe that you cannot have continuous improvement without it. I think the main reason why is because naturally people are not welcome to change, and if you try to implement change without respect or even with respect you can face a barrage of issues. Any comments?

Jacob – thanks for your comment. The field of “Motivational Interviewing” teaches us that “resistance” (or more accurately called “ambivalence”) is a natural, normal, and expected part of the individual’s change process.

https://www.markgraban.com/motivational-interviewing/

I particularly recommend the book “Motivational Interviewing for Leadership.” When issues come up, it’s the responsibility of leaders to work through those issues instead of labeling people as being bad for being “resistant.”

The problem is usually leadership (or a lack thereof), not the people being resistant.

Hey Mark, great article. I feel that the idea of respect for people is often overlooked and I believe the idea of it could genuinely help other companies if the value were only more advertised and broadcasted. This article was the first time I heard about this defining pillar of Toyota so it does not seem like other companies are focusing on it as one of their core mentalities. Do you know about any other companies that share this level of respect for people?

Thanks for reading and commenting, Nathan. Unfortunately, too many organizations out there try to emulate aspects of the Toyota approach — they might try “waste reduction” without also focusing on “respect for people.” There are some companies that seem to focus on respect for people… it’s hard to come up with a specific list though. Your teacher Karl Wadenstein does a great job of this at his company VIBCO, which was apparent the times I was able to visit.

[…] Mark Grabham “Toyota, Respect for People (or “Humanity”) and Lean“ […]

[…] Mark Grabham “Toyota, Respect for People (or “Humanity”) and Lean“ […]

[…] Toyota, Respect for People (or “Humanity”) and Lean […]

[…] Mark Grabham “Toyota, Respect for People (or “Humanity”) and Lean“ […]

[…] Mark Grabham “Toyota, Respect for People (or “Humanity”) and Lean“ […]

[…] Mark Grabham “Toyota, Respect for People (or “Humanity”) and Lean“ […]