Tag: Kaizen

For Big Leaps With New Year’s Resolutions, Start With Baby Steps

Thanks to the Lean Enterprise Institute for publishing my article about Kaizen, new habits, and New Year's resolutions:

Take Baby Steps Towards Improvement

"As 2019 begins,...

Why Would You Go Back To Japan? Haven’t You Been There,...

When I got back from Japan a few weeks back, somebody at a hospital client of mine asked me:

"Why go back to Japan again? Haven't you been there, done that?"

Why go back to Japan? Why not go back? I learn something new and have great experiences each time and my recent opportunity to tag along with Honsha was no exception.

GE Gets a Lean CEO — From the Outside

Jet lag, even well managed and planned for, meant I was awake early on a Sunday morning. Over breakfast, I read more about news from last week, that GE had fired their CEO John Flannery after 14 months and replaced him with a relatively new board member, Larry Culp.

Culp is GE's first outsider CEO hire in their 100+ year history. So who is this guy and why did they hire him?

Culp was CEO of Danaher, a company that's quite often held up as the best non-Toyota Lean company out there. And they're an American company. Danaher, through its Danaher Business System (DBS) approach, uses Lean as a business strategy in a way that's very different than Toyota. Danaher has acquired companies and brought DBS and Lean in as a way to turn around and improve those businesses.

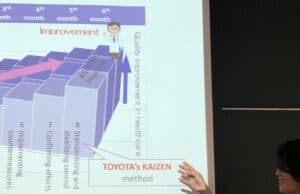

More on Teaching TQM, TPS, Lean, and Kaizen to Doctors in...

In the third and final part of this series, I share more about how Toyota teaches about TPS and TQM... and how they are sharing that approach with doctors and hospitals.

Kaizen in the Garrison Brothers Bourbon Bottle Dipping Process

I'm excited that our sold-out "Symposium on Learning Organizations" group will be visiting Toyota's San Antonio plant on Wednesday. Later that day, we'll be touring the Garrison Brothers Distillery and, on Thursday, we are using their "barrel barn" as a venue for "Open Space" discussions, the Red Bead Experiment, and more. We have a group of 40 from many industries attending and we might run a similar event in a different location in the future.

I've blogged about Garrison Brothers and my stint as a bottling line volunteer before...

In that post, I shared pictures of me working to dip bottles of bourbon into a sealing wax. I was wearing a winter coat because it was February in Texas and there was a bit of snow and ice that week.

When I was back there recently, I saw some additional improvements that seem like "Kaizen" to me.

TQM at Toyota and the Influence on Lean – Past and...

I'm very excited to be leaving for Japan for another study trip in just over a month. This will be my second trip this year, this time with Honsha, after previous (and hopefully future) trips organized by Kaizen Institute.

Even though the previous tours have been focused on Toyota, as well as Lean and Kaizen in various organizations, one common thread is Total Quality Management, or TQM. In many Japanese organizations, TQM has been a solid foundation of practice for two or three decades, where it tended to be a fad here in the U.S., as I've blogged about:

Are You a Good Coach? An Effective Coach? HBR Says You...

Some colleagues recently sent me a Harvard Business Review article that has a fairly accusatory title, although many readers might think it applies to other managers:

Most Managers Don't Know How to Coach People. But They Can Learn.

It's a common dynamic for people to overstate their own abilities. When it comes to "coaching" in the workplace:

The One Where I’m Interviewed About Lean in Healthcare (and Also...

Somebody pointed Dominic Rubino to me as somebody who could be a guest on his podcast. His podcast is focused on cabinet makers and woodworkers. I don't know anything about that field. But, I think our conversation goes to show that concepts of Lean, Kaizen (continuous improvement), and practices for metrics are pretty transferrable across industries.

The Catch-22 of Lean & Kaizen: You Get More ROI by...

This post builds off of a little rant I went on over on LinkedIn. I wrote:

The Catch-22 of "Lean" training and "implementation"...

Executives want big returns and high ROI. That's understandable.

But, at the core of Lean, if you're going to call it that, is "#Kaizen," which means allowing everybody to do small improvements even if there isn't big ROI.

It’s Exciting to See an “Idea Board” at Buffalo Trace Distillery

Thanks to posting about the trip on LinkedIn, I learned that Mike Bukowski is now working for Sazerac, the parent company of Buffalo Trace, in a process improvement role. Last year, Mike attended the site visit and class that Joe Swartz and I hosted at Franciscan St. Francis Health.

Mike has embraced might call "lessons from Toyota," as taught to healthcare people, and is now training and coaching people who make some very fine bourbon, including Aaron Krentz, Processing Supervisor (at right).

Presentation About Kaizen and KaiNexus From 2013 [Video]

Recently, I stumbled across some video of me and Dr. Greg Jacobson giving a talk at a health system. I think it's from 2013. So, I'm sharing this as a "Throwback Thursday."

KaiNexus software has changed and evolved a lot in five years as the company has grown. Kaizen, or continuous improvement, principles and practices are timeless.

What Do Cars Have to Do With Healthcare?

Today, I'm giving a talk at the International Society for Blood Transfusion (ISBT) conference in Toronto. I was invited by the company Quotient to participate in a panel presentation and discussion with some laboratory professionals from the U.S. and the U.K.

The others are presenting examples of how they have improved flow, productivity, and quality in blood collection and hospital blood bank settings. Lean often gets portrayed as just being about efficiency or flow, when Toyota's definition of the Toyota Production System talks about how flow and quality go hand in hand.

I was specifically asked to give a short talk titled, "What Do Cars Have to Do With Healthcare? How to Adopt and Adapt Lessons From Manufacturing."

![Presentation About Kaizen and KaiNexus From 2013 [Video]](https://www.leanblog.org/wp-content/uploads/2018/06/Screen-Shot-2018-06-06-at-2.42.33-PM-300x194.jpg)