I'll blog more about my recent trip and “gemba visits” to some bourbon distilleries in Kentucky this past week. Well, they were really the public tour, except for two very cool opportunities.

One was my chance to visit David Meier and his Glenn's Creek Distillery (as we talked about in Episode #309 of the podcast). I'll share more about that in a future blog post.

Thanks to posting about the trip on LinkedIn, I learned that Mike Bukowski is now working for Sazerac, the parent company of Buffalo Trace, in a process improvement role. Last year, Mike attended the site visit and class that Joe Swartz and I hosted at Franciscan St. Francis Health.

Mike has embraced might call “lessons from Toyota,” as taught to healthcare people, and is now training and coaching people who make some very fine bourbon, including Aaron Krentz, Processing Supervisor (at right).

We're pictured in front of the “Idea Board” that they started using last month. You can see they've already completed some small improvements on the theme of “make your work easier” along with some company goals. I loved hearing Aaron describe what they're doing to improve their process. What a special opportunity this was.

Everybody who does work has ideas about making their work easier, better, faster, and cheaper. Leaders like Aaron can participate and draw ideas out of others. People like Mike can help coach them through this process.

As Masaaki Imai says, “Kaizen is for everybody.”

It's great to see that spirit (pun intended) at Buffalo Trace.

There are a few factors that are in their favor, I think.

One is that the company decided in the early 1990s that they would stop laying off employees during slow times. Bourbon has had many boom and bust cycles over the past 200 years. When you have a product that requires years of aging, it's very hard to forecast demand.

Our tour guide said that the company decided to tap into the many different talents that their employees have, putting them to work in different ways instead of viewing them as a cost to cut. They were down to just 50 employees in 1992 and, thankfully, they have been in a growth mode since.

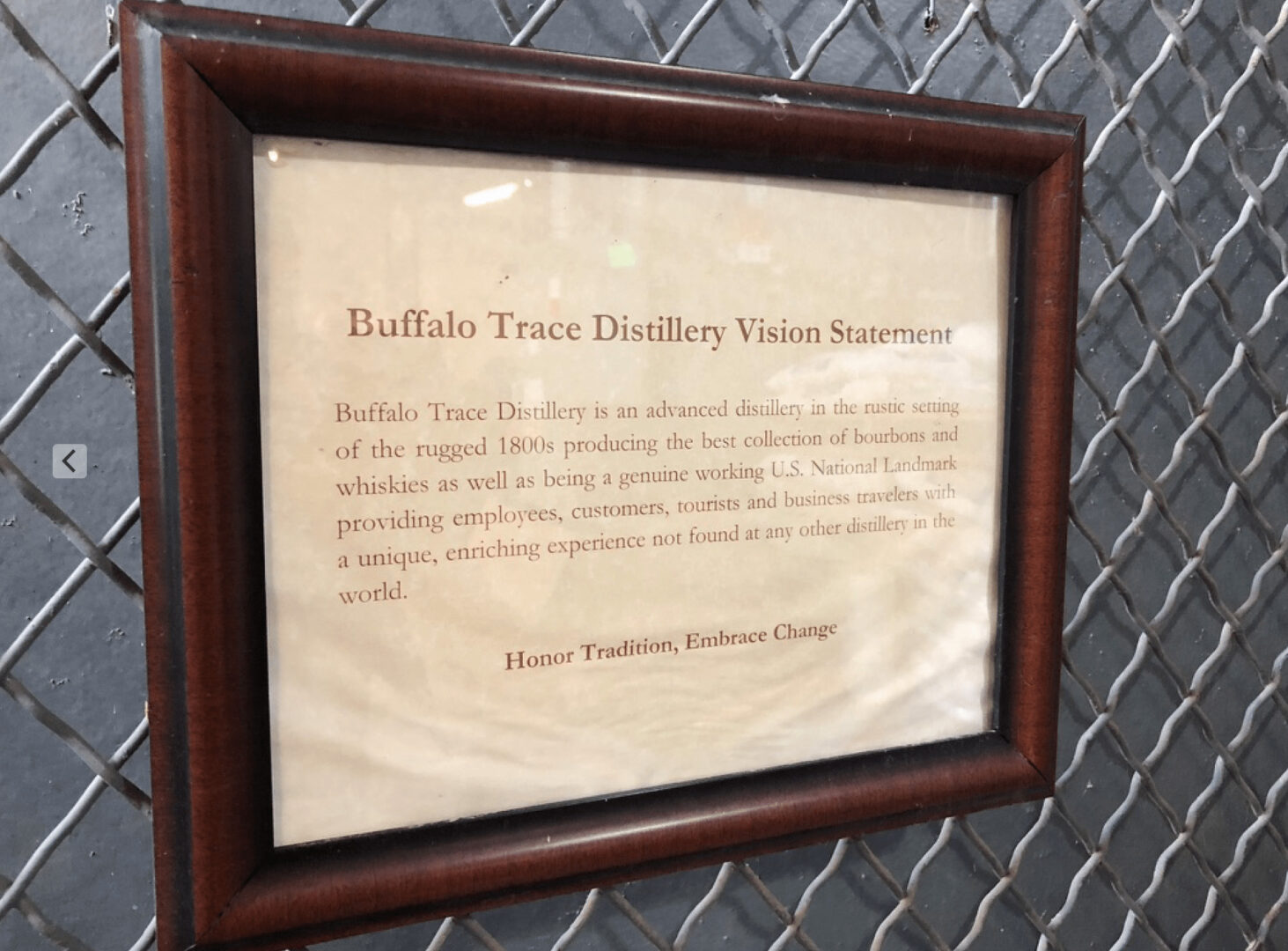

A second factor is their corporate slogan of “Honor tradition, embrace change.”

That sounds like a great foundation for continuous improvement! I'm really curious to see how this develops over time.

Here are some more photos:

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![What’s Your Organization’s Real Mistake Policy? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-17T085114.134-100x75.jpg)

Here is the post about this on LinkedIn: