I was at an organization recently where one of the relatively senior leaders kept using a curious phrase that made my ears perk up.

The senior executives were continually being referred to as “the decision makers.”

To me, that's a really bad sign. That's part of the culture that we're trying to change with Lean and Kaizen principles. To their credit, this organization is trying to create a “culture of continuous improvement.” Their executives “support” continuous improvement and are “supportive” of the idea of everybody being involved improvement.

The question is whether than can shift from being generally “supportive” in principle to learning when to allow decision making to happen lower in the organization.

It inspired me to create this graphic:

In a Lean culture, the executives still play an important role. They have important decisions to make about strategy and really important high-level decisions, although they might “play catchball” to help test ideas and get input from other levels of the organization as appropriate.

But, the executives need to stop micromanaging improvement work that's taking place (or being stifled) at lower levels.

In Lean, we believe that everybody is an expert in their own work. Therefore, the frontline staff are best positioned to identify and solve problems related to their work.

The role of managers shifts from having all the answers and doing all of the work to being a coach and a facilitator. The executives act as servant leaders rather than the people who swoop in to fight fires.

There's a story that I use in presentations and it's in Lean Hospitals as a mini case study about what can go wrong when executives try solving front-line problems from on high (or from across the street in their executive offices):

One U.S. hospital was a few years into its Lean journey, yet the CEO still made many top-down decisions. Patient surveys showed that late-night noise was the biggest cause of complaints. Inpatient unit managers were, needless to say, surprised when workers arrived to install carpet in the hallways. Unfortunately, the new carpet made it physically harder for nurses to push computer carts down those hallways, so they spent more time at the nurses' station. One executive mandate (use technology to get out from the station) ran into conflict with the other mandate (carpeted hallways). Instead of following a plan-do-study-adjust (PDSA) cycle, the carpet was introduced to other floors before the impact on the first unit was fully determined.

Ironically, patient satisfaction data showed that noise complaints dropped starting the month before the carpet was installed. Why? Nurses had taken initiative to make a number of small improvements, such as closing doors and turning TV volumes down at night. So, as nurses were learning Lean principles and their executives said they supported that effort, the senior leaders were not yet thinking Lean themselves.

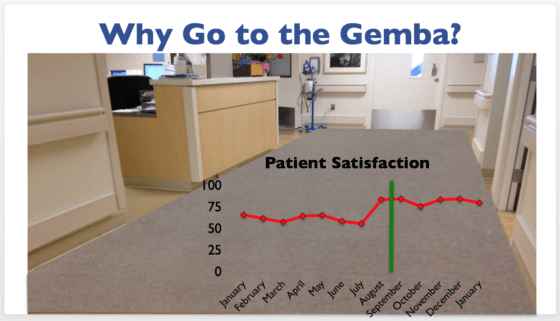

Here is a slide I use in presentations:

Executives should go to the “Gemba” (the place where the work is done)… or better yet, they can let local teams and managers come up with ideas and solutions, as they did in this mini case. What the nurses did, their small actions, could all be considered “Kaizen” activity.

And, as the chart shows, patient satisfaction (the scores, at least) went up BEFORE the carpet was rolled out (the green line in the chart's x-axis).

Do you hear people in your organization referring to executives as “the decision makers?”

What are you doing to help EVERYBODY make decisions at the appropriate level and the right scope?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-238x178.jpg)

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

I have run into this problem at the Agency I’m working at, but I think it’s more of a cultural problem as you alluded to Mark. Yes, the leaders are making strategic decisions, but all too often, they are micromanaging improvement work that’s occurring at lower levels. Any improvements have to go through layers of leadership within most organizations in the agency. I find it so demoralizing when “the decision makers” don’t approve countermeasures during improvement work. Leaders are supposed to be serving and inspiring not commanding and inducing fear. As far up in the leadership that I’m able to influence I try to coach leaders into new ways of thinking and behaving. From telling to asking, from fear based to curiosity based.

I heard a great story on this theme at the European Lean Healthcare Transformation Summit from a presenter.

They talked about how an executive had an idea to buy a month’s worth of diapers at a discount.

Thankfully the executive came to the maternity ward and staff quickly pointed out they didn’t have enough storage space for the huge purchase.

So, the exec changed their mind.

The power of “going to the gemba” and getting input from people. Go figure.