Last week, I had a chance to sit in on a leadership class that was co-taught by Dr. David Munch (listen to my podcast with him here).

During the class, there was a case study discussion about a hospital that was trying to solve the problem of nurses not always scanning patient bar codes and medications 100% of the time.

In the discussion, I was disappointed that an attendee fell back on saying:

“We'd hold staff accountable.”

When I hear that phrase, I always have to ask what they mean.

Unfortunately, it too often mean “we'll blame and punish them.”

I've written about this before:

As I've blogged about before, it's not “accountability” to blame staff for problems that are out of their control:

Redefining Accountability: Shifting from Blame to Constructive Action in Lean Practices

As I thought about this more, I wondered if hospitals that would “hold staff accountable” for some sort of problem had ever engaged them and asked them how to solve such a problem?

Did managers and executives listen and help when staff tried to speak up about problems and their ideas?

If not, it's totally unfair to try to force accountability on people who you haven't allowed to BE accountable.

Kaizen – the process of engaging people in identifying problems and testing improvement ideas in a Plan-Do-Study-Adjust requires teamwork. Teamwork requires mutual respect — and if respect isn't there, it's on leaders to start creating a respectful environment.

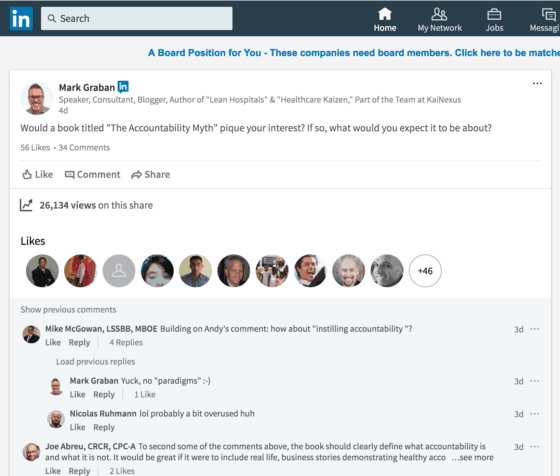

When we have respect, teamwork, and Kaizen… then we can actually have accountability. That's true accountability… what somebody described as “healthy accountability” in a LinkedIn discussion I started the other day.

I'd be curious what you think about this topic. Would a book titled “The Accountability Myth” pique your interest?

I think the myth is that accountability is something that a leader can force on others.

The myth is that “naming, blaming, and shaming” leads to improvement and success.

We need alternatives… we need leaders who are willing to work together with employees to identify and solve problems instead of just “naming, blaming, and shaming.”

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Perhaps we should hold leaders accountable to the front line staff — that’s what Varsity Facility Services does: http://www.markovitzconsulting.com/blog/blog/reversing-the-vector-of-accountability

Or, we can hope leaders choose to be accountable. I’m not sure how we “hold anyone accountable.” Accountability is a personal choice… and sometimes we’re not in a position to “take accountability” for stuff that’s out of our control…

I would absolutely be curious about a book titled “The Accountability Myth”. In my experience certain crisis events bring a singular purpose to a team that let’s them focus on *what* needs to be done much more than *who* needs to do it. “Who” is important, but not at the expense of the “what”.

I absolutely agree with you sir. The leaders in the business should take a stand in training their employees to be more efficient. The Plan-Do-Study-Act would be a better way to improve the process and minimize errors. In my learning as a masters student in Industrial Management there should be Continuous Improvement in a company of any field. I would like to know what methods can be implemented in a field like healthcare, hospitals and pharmaceutical companies to make it easier for the staff to understand lean and make no errors as, these fields directly deal with humans and there is no chance for errors.

I’m glad you agree there should be continuous improvement in any setting.

Lean is a set of methods and a mindset. I’d suggest learning about mistake proofing and error proofing, among other concepts. I’d also suggest reading Kaizen as an improvement method and mindset. The management styles and leadership approaches matter greatly when it comes to engaging people.

We have to shift from blaming people to improving processes. See the recent Oscars problem (and my post about it) for an example of a bad process tripping up good people.