Mark's Note: Thanks to Sam Selay for today's guest post. Although he's writing about the government and the military, I think you'll find this post interesting regardless of your industry. Read an excerpt from Sam's chapter of Practicing Lean.

Sam Selay is working at Optimize Consulting, where he is an on-site consultant for the Defense Logistics Agency. The Defense Logistics Agency (DLA) is an agency in the United States Department of Defense, with more than 26,000 civilian and military personnel throughout the world. Located in 48 states and 28 countries, DLA provides more than $34 billion in goods and services including repair parts, acquisitions of weapons, food, fuel, energy, uniforms, medical supplies and construction material.

Sam Selay is working at Optimize Consulting, where he is an on-site consultant for the Defense Logistics Agency. The Defense Logistics Agency (DLA) is an agency in the United States Department of Defense, with more than 26,000 civilian and military personnel throughout the world. Located in 48 states and 28 countries, DLA provides more than $34 billion in goods and services including repair parts, acquisitions of weapons, food, fuel, energy, uniforms, medical supplies and construction material.

Background

After practicing Lean and Six Sigma in the United States Marine Corps for six years, it became apparent that there were current behaviors and practices that were preventing the organization and the Department of Defense, as a whole, from realizing enterprise excellence. From my perspective, some of the prevalent thinking around Six Sigma had heavily influenced these behaviors and practices.

As I was finishing my tenure with the Marine Corps in 2016, I was approached and offered the chance to work as a Continuous Improvement consultant within the Department of Defense.

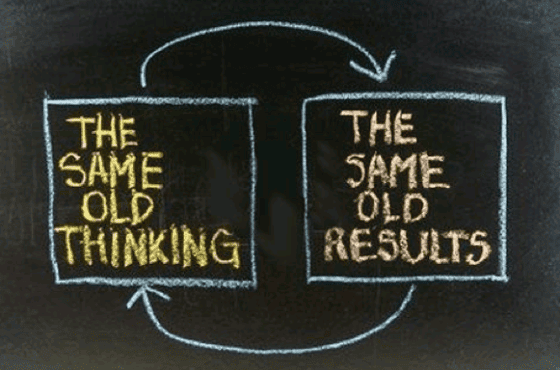

“If you keep doing what you've always done, you'll keep getting what you've always got.”

-Anonymous

The Same Old Approach

From my experience, traditional Six Sigma thinking and practices have failed to delivered true transformations across industries. I personally think Six Sigma can complement Lean or other improvement methodologies, but when the focus is on training belts and experts doing projects, the initiative is doomed to fail. This approach does not engage employees and does not focus on developing problem-solving capabilities in others. Quality improvement is not the experts' responsibility, it's everyone's responsibility. At the Defense Logistics Agency (DLA), where I'm currently consulting, training belts and experts running projects had always been the status quo, until now.

Prior to me joining the organization, approximately 1,800 belts had been trained. The results of this training was miniscule. Today, the improvement practice has completely shifted with the focus on developing a community of problem solvers with a heavy focus on coaching. The main role of the improvement experts has now shifted from leading projects to developing problem-solving capabilities in others through coaching.

Training

Why conduct training? Why spend limited time, money, and resources on traditional training? After 1,800 trained belts and minimal return, why continue to do the same thing and expect a different outcome? Today, Lean Six Sigma green belt and black belt training is outsourced. If an organization within the agency wants to send their employee to training, they are provided a list of recommended training institutions. They should then own the responsibility of selecting and supporting those employees. In addition, it's highly recommended that they start practicing what they are learning with the oversight of a coach as soon as possible, preferably while they are still going through the training.

The focus now at DLA is delivering results, not conducting classroom training. We've come to the realization that improvement experts are better utilized as coaches versus being classroom instructors. However, if during a coaching session with the learner it's evident that a necessary tool such as a fishbone diagram, Pareto Chart, control chart etc. is needed, and the student is unaware of the tool, the coach will shift into teaching mode. From my perspective, this is the best type of training. The student should learn the tool, think how to use the tool, experiment with the tool, reflect, and adjust how the tool is used next time.

Tools

Traditionally, there has been a heavy focus on tools for any number of reasons. However, at the core, tools are simply countermeasures to problems.

At DLA, we have shifted away from checklists of required tools and heavy requirements to the thinking behind the tools. Why are you using that tool? How will that tool help you solve the problem? The focus now is having the coaches force the learners to think deeply and critically through the problem-solving process.

For projects, the only requirements now are a charter, A3, and executive summary. Why use a 50-page power point presentation when you can present the most vital information on a single A3? To clarify, it's not about the A3 document, but the thinking behind the document. We are concerned that people are demonstrating root-cause problem solving through the use of the A3.

Give a man a fish and you feed him for a day. Teach a man to fish and you feed him for a lifetime.

-Laou Tzu

Coaching

I strongly believe that the cornerstone of this shift in the practice is coaching. I'm paraphrasing John Shook from the Lean Enterprise Institute, who said, “When you give an employee an answer, you rob them of the opportunity to figure it out themselves and the opportunity to grow and develop.”

We have to help people by taking a completely different approach. People will not develop problem-solving capabilities when you tell them what to do or what tools to use. People will develop problem-solving capabilities by thinking, experimenting, learning, reflecting, and adjusting.

The role of the coach is to guide the learner by forcing them to think critically through the problem-solving process. This is done through the use of Socratic questions. Some sample questions that can be used are:

- What problem are you trying to solve?

- How do you know it's a problem?

- How big is the problem?

- What is the data telling you?

- How can you visually display that data?

- What causes that to happen?

- Why do you think that countermeasure will address the problem?

- How will you know if that countermeasure has been successful?

- How will improvements be measured? When? Who?

- What new problems have surfaced? Are additional countermeasures necessary?

- What will you do next?

However, if it's clear that the learner doesn't know what to do, is unaware of a tool, or has a misunderstanding that needs clarifying, then the coach will shift into teaching mode.

The journey to shifting the improvement practice at DLA has just begun. There are many other elements that also must be addressed, such as influencing leadership's beliefs and behaviors, driving out fear, clarifying the most important improvements to do, focusing only on the vital few improvements, building the practice through a disciplined approach focused around developing others problem-solving capabilities, and engaging everyone in improvement work at all levels.

As new leaders and employees join the organization and challenge the direction of the improvement practice we must pause, reflect, and ask ourselves do we want the same results that we have always got? Do we want to train belt and lead projects or solve problems and develop internal problem-solving capabilities? We have chosen the latter, and the path to get there.

Sam Selay has been involved in Continuous Improvement since 2010, and has been using Lean and Six-Sigma methodology in the military and the federal government. He worked in the United States Marine Corps in supply chain, logistics, quality, and continuous improvement for 13 years. Currently, he is working at Optimize Consulting, where he an on-site consultant for the Defense Logistics Agency. He has a BS in Management Studies from the University of Maryland University College, a MBA in Management and Strategy from Western Governors University. Sam is a certified Lean Six Sigma Black Belt from the University of San Diego.

Sam Selay has been involved in Continuous Improvement since 2010, and has been using Lean and Six-Sigma methodology in the military and the federal government. He worked in the United States Marine Corps in supply chain, logistics, quality, and continuous improvement for 13 years. Currently, he is working at Optimize Consulting, where he an on-site consultant for the Defense Logistics Agency. He has a BS in Management Studies from the University of Maryland University College, a MBA in Management and Strategy from Western Governors University. Sam is a certified Lean Six Sigma Black Belt from the University of San Diego.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

I am glad that I came across this article because I totally agree with its message, especially about the training and coaching versus teaching part. This is because indeed there is a need for those trainees to know what they are going to be trained for and have enough background information so they can apply it as they work on actual cases of problem solving. but like it is mentioned in the article, spending all that money and resources in the classrooms is not very efficient. this is why personally, instead of going for a training like that, I choose to get a certification in the implementation of lean six sigma as I am doing my Masters education in Industrial Management. While I am taking classes for my masters program, I am learning about the implementing LSS and as long as I excel in those course, I get the certification in implementation with my diploma. This let’s me kind of double dip, and get that baggage I need when I am later on working on process improvement and want to use those concepts in real life and apply them. Otherwise, what do you think would be a solution to educate and inform employees about continuous improvement and quality management? Because I believe that they need to gave knowledge about those methods and tools before they attempt to make a change or take on a project.

When it comes to learning, you must practice, with the oversight of a coach. Minimum classroom learning followed directly with application. I like the see one, do one, coach one approach. The coach teaches problem solving by leading improvement workshops with internal resources. Internal resources start to practice problem solving with the coach. The internal resources begins to build competency through continuous learning and practice until capable of doing on their own. Internal resources begin to teach and coach others within the organization. Internal resources begin to teach and coach others within the organization. We practice medicine, law, etc. Why should it be any difference with Lean?

Hi,

I think that the coaching approach that you talked about is very interesting. Coaching employees will help them come up with the solutions by using their own ideas. Also, it helps them practice their problem solving skills.

On the other hand, I believe that training is just as important. Without training, some aspects of the work and process may not be done correctly. Each person has their own way of dealing with situations, by training employees, you will be able to unify the process that employees will take to complete a task.

If employees took different steps to accomplish the same task, the time it would take to accomplish that task would be different.

What do you think?

Your response is much appreciated, thank you.

Serien,

Thank you for the response. As I noted in the post if an organization within the agency wants to send their employee to training, they are provided a list of recommended training institutions. They should then own the responsibility of selecting and supporting those employees.

We have done the analysis and found that improvement experts time is better used coaching and developing others problem solving capabilities, rather than teaching courses in a classroom. There are great training organizations that are available, why not use them?

One of the coach’s role is to ensure that the practitioner is practicing improvement correctly in aligned with the defined problem solving methodology. JIT training can be used by the coach to introduce new information that the practitioner does not know, and to clarify misunderstandings.

I see the improvement coach very much like a sports coach. They guide and direct the practitioner to a desired target. How they get there may vary, but the student must learn, grow, and develop on their own. Some times they may have set back and failures, but the coach must not go into “do-er” mode, “rescuer” mode, or “fixer mode. The coach cannot do the work for them, just as a sports coach cannot take the field for the athlete.

Does this answer your question? If you have any follow-up questions please let me know.

Sam

Sam,

Thank you for your quick response.

Yes, you have answered my question. But I still see an issue where time is of value. Since each person will go about things differently, wouldn’t that be a “waste” of time if some did the task faster than others?

How does coaching come into play in this scenario? eventually you would have to train the person to accomplish the task the fastest and most efficient way possible, wouldn’t you?

Serien

Serien,

The training I’m referring to is only improvement training. Training on job instructions, standard work, etc. is done by content experts at planned intervals. Improvement coaching only comes into play when doing improvement projects, events, daily kaizen, or other improvement related activity. Content experts should be teaching, coaching, and developing their people and managing the work. This includes training everyone to standard work. Content experts also conduct training after standards are changed following a improvement.

Does this clear up your concerns?

Sam

Yes thank you so much.

I belive that coaching is definitely the way to go, but what about the knowledge and information the person needs to aquire before taking on the task and jump in a hands on work ? I know you said that the coach can turn on the teaching mode, but isn’t that going to be waste of time? Don’t you think that in this situation, if a company wants to educate their employees about Six sigma, they should at least have an orientation process before the coaching ? This way they save time, which equals money!

Any input is much appreciated!

Maroua,

As I noted in the post if an organization within the agency wants to send their employee to training, they are provided a list of recommended training institutions. They should then own the responsibility of selecting and supporting those employees. The coach will then work with the employee to apply what they are learning to improve their work. There are two situations how I engage with employees that do not have any improvement training. I use JIT training throughout the project or they attend training and I coach them during or after their training.

Sam

Hey Sam,

My understanding was that it is more efficient to skip the training part and go straight to coaching in order to save time and money. That is why I thought about the orientation part to at least cover some of that background and information needed to gide the employees throughout the process. Another way can be using e-learning to let employees get that theory knowledge so then they are more than ready for the coaching part ! What do you think on that ?

Thank you for the response.

Great post thanks Sam.

I am a coach and I am aligned with your views.

There are two situations where training is useful. I find that some lean construction courses run in the company I work for have the effect of driving pull for coaching and lean implementation. This is to be encouraged. The second situation is interesting as I have been employed previously in a LSS shop but refused to do belts as I lean towards lean and don’t believe in belts. This has made it difficult to secure other CI roles as belts are often seen as a positive attribute by employers and therefore a prerequisite.

Keep up the great work!

Kevin