When I teach about Kaizen and continuous improvement, I try to use scenarios and cases to help people think through how they would respond to, coach, and collaborate on employee ideas.

One key point is that leaders have to thank employees for pointing out problems or opportunities for improvement. They need to do so even if they think the idea or proposed solution isn't ideal or might not work.

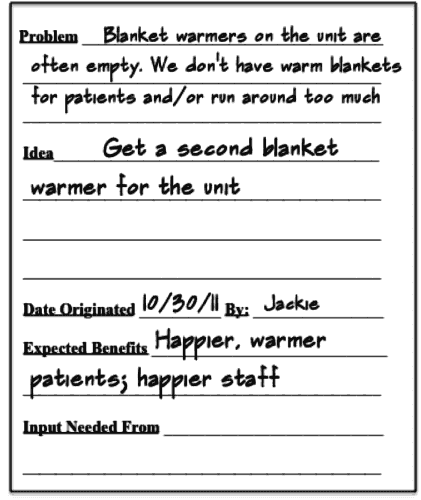

Here is a “Kaizen card” that I usually show in my training and coaching sessions, a real scenario:

The problem is a legitimate one, with two components to be recognized

- We need to provide warm blankets to patients when they are needed

- We shouldn't make staff run around too much

When the blanket warmer is empty, bad things happen:

- Patients have to wait for blankets, which reduces their comfort and patient satisfaction

- Staff, who are already busy if not overloaded with work, waste time and motion looking for blankets and delaying other patient care activities

- This might make staff grumbly or short with people, further hurting patient satisfaction

- Staff might start hiding or hoarding blankets, which might further throw off the system

When I ask workshop participants how they would react to the idea of “add a second blanket warmer,” a number of people usually scoff and make a noise or shake their heads.

I ask them why, and they usually say something like, “We'd just have two empty blanket warmers!“

That might very well be true. So how do we respond? What comes next in this workplace scenario. I see two options when the manager thinks an idea like “adding the second blanket warmer” won't work or isn't the best solution.

- Let people try and learn experientially

- Ask questions and try to better understand the cause of the empty blanket warmer

I've been taught to have a “bias for action” but also to “look for the root cause.” That's conflicting advice, eh? So what do we do?

Listen to Mark read the post (subscribe to the podcast):

Option 1: Let people try – PDSA

There are circumstances where we should let people try their idea, even if we think it will fail. Of course, if the manager thinks an idea would be unsafe, you would not want to try this approach of “just try it and see.”

In my scenario, let's say these situations exist:If you say “no” to people's ideas, you might demoralize them, even if you're right. It's possible that the manager is WRONG about what will work or not work, because they're not as close to the work as the person with the idea.

- There's a spare blanket warmer somewhere in the hospital

- There's space in your unit for a second blanket warmer

You might want to err on the side of “let people try.”

Why? It's not like you're having to spend money on a blanket warmer. To install the second one in your unit probably just requires a bit of time and effort. You'd have to get materials management to deliver more blankets (doubling the “par level” perhaps).

It's possible that doubling the par level is exactly what's needed. It might not be the ONLY way to solve the problem, but it might work.

Or, it's possible that you'd just end up with two empty blanket warmers.

If that happens… what's the worst that would happen? You didn't spend any money. You maybe extended the problem a bit, delaying it being solved. But, the people who suggested the idea and tested it… hopefully they would learn.

You'd have to react well to this as a manager – do NOT say “I told you so” or make them feel bad for trying something that didn't work. Hopefully, you could guide people to look for an underlying root cause.

Option 2: Push back, challenge them to look for root cause

You could skip “let them try” and, as a manager, push back… respectfully and constructively challenge people by asking questions that prompt a better understanding of the current state instead of jumping to a solution.

Questions that often come up in my classes, include:

- Do we know why the warmer is empty?

- Do we understand the current process for restocking the blankets?

- Is the par level wrong?

- What's the delivery frequency? Does that need adjusting?

- Who is responsible for restocking (is it a standard process)?

- Are blankets being used inappropriately?

- Are blankets going home with people?

Instead of jumping to add a second blanket warmer, there's a lot we could understand about the current state.

If we did NOT have a spare blanket warmer sitting around or if we didn't have space in our unit. I'd probably err on the side of trying creativity and process improvement before adding more equipment.

Even if we tried Option 1, to try the spare blanket warmer, we might STILL want to try option 2. Option 1 might be quick and might “solve” the problem temporarily… but we might still get a better solution by getting to root cause.

I understand the appeal of Option 2, but if employees are sensitive and easily discouraged, our constructive pushback might just be viewed as negativity and people might disengage.

There's no easy answer. Option 2 is logically ideal, but people can be complex, emotional creatures. We want people to try things and learn. Does that trump the need to get the “right solution” as soon as possible?

It's interesting to me that Toyota will say that the priorities in process improvement are:

- Developing people and learning

- Solving the problem

So that would mean Option 1 is the right approach? Or, can they learn through Option 2?

What would you do?

Assuming you DID have the spare blanket warmer and the space for it… would you choose Option 1 or Option 2? Please share your answer and your reasons why as a comment on this post.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Great case study Mark! I would suggest applying both approaches. You make excellent points about trying to encourage people when they have ideas and to “go do now” and also teach them about rapid root cause analysis. One might suggest adding the second blanket warmer as a “containment action” while exploring the root cause of the empty blanket warmer. I think the heart of this post is to make sure we are encouraging the heart of employees first and worrying about solutions second.

I always say “let’s try it!” The worst that can happen is you learn something. And that’s hardly a bad thing.

BUT – sometimes I’ve found “let’s try it!” ended up being “who will plant the wheat?” Took me a while to learn that, so now it’s very explicit: Your idea, you lead implementing, we all help.

Option 2, no question. The process matters, and I think that even if the employees are sensitive and easily offended, I find both of those things are circumvented when you work WITH them to discover the problem (queue times, refill rate, cleaning procedures, cleaning volumes & processing time, etc), and then fix it! Make them part of the team, part of the solution, and it stands a much stronger chance at lasting. The very last thing you want to do is re-visit this issue 8 months down the road, so it’s better to build a solution that will continue to be one. Just like Toyota says, develop the people first!

Why not do option 1 and option 2 simultaneously? You have an extra blanket warmer, providing that would show staff support and decrease emotional apathy. Secondly, have staff work on a process to keep blankets stocked and equipped. When leaders can eliminate barriers or provide tools and resources, teammates will partner to develop “best practices” and find root causes.

Both options using the A3 report…PDSA requires some form of root cause analysis…

In my experience, PDSA does not always require root cause analysis. We don’t need to overanalyze every small improvement. We want to move the table from here to there. Who cares what the “root cause” is for why it was in the old location. Just move it (Plan and Do) and then Study the impact and Adjust if needed… PDSA with no RCA.

Very good post…i like it. I had similar experiences in the past in my workshops. when dealing with such scenarios…i always recall Don Wheeler’s statement

If your current process is not predictable,then what makes you to think that the new process can be predictable.

So, a manager’s primary responsibility is “Prediction”. if it is so..no surprises in the business…and this reminds me now another quote from a movie…

“Nothing surprises me as am a scientist”…i think its IndianaJones movie?

Thanks for sharing. The decision can be situational as you mentioned. However, as a general approach, I’d go for both options simultaneously. Acknowledge the idea they come up with, yet encourage to look for other alternatives before implementing. Use a quick 5 why or a fish-bone sketch (by sketch I mean quick and simple),then vote on the best action as a group.

The reason I’d do both is to still encourage staff to come up with ideas and improvements all the time, yet teach them that it’s not what we always see first is the best answer, and understanding the problem even in the most simple way is always important. Striking the balance is where the art comes in!

I am all for disruption, I would question why the blanket warmer is needed in first place and if any alternative options could be implemented instead.

Sorry I don’t like to be boxed just by two choices that might not necessarily address the underlying issue :-)

It’s good to challenge things, Riccardo. It’s not good to improve something that you shouldn’t be eliminating instead.

In this case, the warm blankets are a must… that’s the standard technology for warming the blankets and providing that warmth and comfort to a patient.

Interesting question for sure. I guess I am not that different from the people in your courses, my first instinct is to entice further thought on the matter. When the problem or the solution are about *things* we need, my “reach for the mind before the wallet” senses start to tingle. But in your hypothetical situation, with the possibility of a quick trial, it sure makes the opportunity to really teach people really enticing! show less

It depends. How far along the problem solving capability curve are the individuals involved and the organization as a whole? What is the current level of engagement? Does leadership demonstrate disciplined problem solving?

The ideal condition is that everyone is a problem solver and solving problems well which includes understanding root causes.

Low engagement? Then proceed as suggested and leadership works for improved engagement with involving employees in other problems.

Low problem solving maturity? Then proceed as suggested and leadership works for developing problem solving skills.

Low demonstration of disciplined problems solving at leadership level? Then proceed as suggested and leadership starts demonstrating disciplined problem solving.

Prerequisites above covered? You’re ready to start demonstrating respect for the employees by investing time and effort to improve their disciplined problems solving skills.

What would I do? Oh heck, who knows…it might depend on many, many more things. How chummy am I with the team? Have I already earned their respect and trust, or did we just start working together? Have they shown any resistance to people questioning their ideas in the past….is merely asking a question going to shut them down. I lean towards a bias for action, as long as that action is part of a test / hypothesis.

Between option 1 and option 2, I think I would start with option 1. I would want the staff to engage in some inquiry into what might be causing the problem as you allude to in your post. Option 2 is not a bad solution but to me, it would appear to be jumping to a solution without regard to what is causing the problem in the first place. Of course, there could be other options available (as mentioned by other postings), so there should not be an effort to limit staff creativity in trying to work through the problem and come up with some alternative solutions to test/try.

I would push back……just enough to get them to think. In the end however, I am a big believer in letting areas PDSA because the learning from doing so is really valuable. It should be noted that I would be coaching the entire time.