Yesterday, our tour group had a chance to visit an outstanding factory. They manufacture gas meters and they do everything from casting aluminum, creating printed circuit boards, stamping, painting, assembly – all in a single site. It reminded me a bit of old Henry Ford vertical integration from 100 years ago (which can be a good thing, this old idea).

The plant manager hosted us and talked about their “QC circle” program. This approach to Kaizen, or improvement, has been used in Japan for over 50 years and he said it's “super popular” in Japanese companies of all types, today. That's me, at left, standing by the bullet train back to Tokyo…

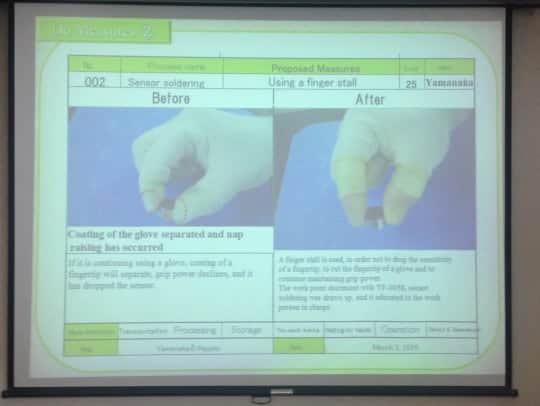

The QC circle is formed within the natural work team and they do improvement projects that are more involved than a “quick and easy kaizen” as Norman Bodek wrote about (see one of those Kaizens as it's documented below… they had many boards like this around the different parts of the plant). This is similar to one format used in our book Healthcare Kaizen.

The plant manager said the “goal” is to have each employee do EIGHT Kaizen improvements per month – but, again, these are small improvements. A good part of each manager's day is spent working with employees on Kaizen (something that's very different, I think, than the way American managers spend their time).

Team members request time for QC circle projects (on regular time, not overtime, usually) and their managers, after some negotiation, will grant it.

As our guide, Brad Schmidt, said (I may be paraphrasing): “The man who can't appreciate the $50 savings won't get the $50,00 savings [in a later improvement].” As I wrote about yesterday, doing lots of small Kaizen improvements allows you to stumble across larger opportunites, as they come up.

There was a representative from a QC circle team (a team consisting of seven men and eight women) about their project to reduce the dropping / falls of product from the line (any dropped product has to be scrapped). This costs 10,000 yen per month… which sounds like a big number, but that's only $123 USD a month.

The team went through some pretty rigorous PDCA problem solving. They collected data on the number of drops and the cost. They did Pareto charts about where, in their cell, the drops were occurring and why. They had a lot of discussion within the team about possible countermeasures. They created a “Kaizen newspaper” of 17 possible countermeasures and prioritized their testing and implementation based on a number of factors (using an evaluation matrix).

The team went through some pretty rigorous PDCA problem solving. They collected data on the number of drops and the cost. They did Pareto charts about where, in their cell, the drops were occurring and why. They had a lot of discussion within the team about possible countermeasures. They created a “Kaizen newspaper” of 17 possible countermeasures and prioritized their testing and implementation based on a number of factors (using an evaluation matrix).

They implemented a number of changes and reduced drops by about 75% — saving about $90 a month.

In this company, they have a “championship league” where different QC projects are selected as winners in different parts of the plant and winners are then selected for each country around the world. There's then a global winner selected each year.

This project, based on its rigor and methodology, was the winning project. One of our other tour group members commented about how rigorous the problem solving was compared to what he had ever seen back home.

An Western manager might scoff and say, “You spent ALL of that time to just save $1000 a year???” The winning project might be determined based on the highest Return on Investment.

In so many of the Japanese organizations we visited, the focus was on developing people and teaching them the Kaizen / QC / QI process.

If they learn and practice on relatively small improvements or small benefits, the employees will have built the skills and confidence needed to make other improvements over time, and some of them are bound to be big.

Here's another blog post written by Thomas and Gert, from Belgium, about our visit.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

This is the same type of thinking I saw on my Japan trip this month and I went to different factories than you.

At Toto (the kitchen & bathroom product company) they talked about how doing small kaizens raise the awareness for breakthrough kaizens.

They don’t start with a breakthrough event that has a long tail of small kaizens that need to be done by individual areas to meet the target. It goes the other way. Small kaizens first that eventually lead to breakthrough.

I also saw the competition aspect in a couple of factories.

On the way back from Japan, I read Robert Maurer’s new book “The Spirit of Kaizen” and he also talks about the idea that breakthroughs only happen when people are open to the possibility…. that possibility being created by the continual practice of small changes. Kaizen makes breakthroughs happen (or more likely that you recognize them when you stumble across them).

What do you mean by competition?