I'm about conferenced out! First was the excellent SHS/ASQ conference on healthcare operations improvement (read my posts), then the HIMSS conference focused on heathcare information systems, now the LEI Lean Transformation Summit that starts today (follow our tweets). As a Myers-Briggs “introvert” (a chatty introvert), I'm ready for some recharge time… this weekend. In this post, I'll tell you about some of the people I saw, an example of bad flow, and a nice lean-related product feature that I discovered.

I saw a number of old friends at HIMSS and made some new ones, including:

- Naida Grunden, author of the outstanding book The Pittsburgh Way to Efficient Healthcare: Improving Patient Care Using Toyota Based Methods (her website)

- Dr. Ted Eytan, from Kaiser Permanente, who I met in person for the first time after years of phone calls and emails (my podcast with him when he was with Group Health, his blog and his tweets)

- “e-Patient Dave,” who I only knew from his tweets and comments on Paul Levy's blog (Dave's blog).

I'll write about Naida's talk on Lean and patient safety in my next post. e-Patient Dave gave a touching talk about his near-death experience with cancer and his fight to make information available to patients and to include them in hospital improvement activities. The most stirring line from his session, answering a question about the ROI that's measured from patient involvement:

There's a special section of hell for people in healthcare who ask ‘What's the ROI of doing what patients want?'”

And this comment comes from a very upbeat, cheery guy.

Now to the bad flow example:

HIMSS was held this year at Atlanta's convention center, the Georgia World Conference Center. This is a huge conference (30,000 attendees), so it's understandable that it's a big space. But I've never seen a convention center with so many ups and downs required to get from point A to point B. Lots of escalators. Tons of escalators.

Compared to elevators (a batch-and-queue system), escalators have continuous flow. But having flow isn't enough if you don't have capacity. There were HUGE backups of people waiting to get on the escalators. If you ever wondered what a bottleneck looks like, see the bottom of the escalator. This doesn't even begin to convey the massive number of people waiting around the corner.

The flaw with the setup here (and other places) was that there were no stairs. Just the escalator. Areas that had escalators AND stairs had no bottlenecks. Seems like a better design…

Finally, the product design issue.

Nurses and patient care techs often use “Computers on Wheels” (COWs) — often called “Workstations on Wheels” (WOWs) since I heard of a story once where a patient heard the nurses talking about “cows” and the patient got offended because they thought the nurses were talking about them!

These mobile computers require charging. Normally, the charging process means the device is no longer mobile! It's stationary and plugged into the wall. This either keeps nurses away from the patients if they're charting or means they have to walk to access information – lots of waste involved, if anyone notices (other than the nurses themselves).

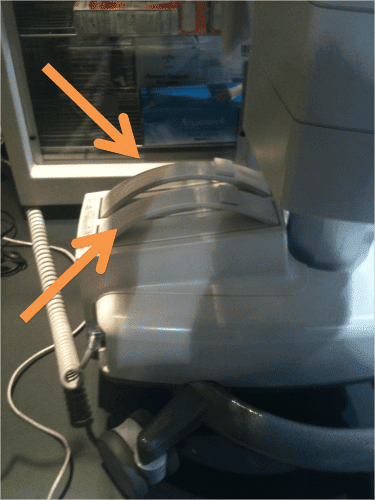

There must have been 10 vendors for these mobile carts (not a very differentiated product, it seems!). Almost all of them have an electrical cord coming from a sealed metal (or plastic) box, which houses a battery. A fixed, very hard to access battery, as pictured below. These batteries often don't last an entire shift – they clearly don't support the nurses and staff members and their needs!

One vendor had a very unique design. Instead of a single, fixed battery (typically “a car battery – lead-acid,” said the rep) that requires a stationary charge, this COW/WOW had batteries that were:

- Lithium-Ion (saving 35 pounds and giving better ergonomics)

- Removable (they snapped out and into a charger like a cell phone batter, well except iPhones)

- Multiple (2 batteries that could be removed separately)

- Long lasting (9 hours per batter — EACH — the rep claimed)

It's pictured below, I'm pointing to the two removable batteries in the base.

These batteries are a new feature in their product. I wasn't able to ask if they saw the need based on observing users at the “gemba” where the product was in use. Either way, it seems like a brilliant helpful innovation. I don't know if it costs more than a regular COW/WOW. I'd lean toward these just because it seems to meet the minimum requirement for allowing staff to be productive and patient-focused. Less hassle, less frustration — do you know anyone who is using these carts with removable batteries? I bet it's a huge time saver for the staff… seems like a great idea unless you're breaking Dr. Deming's rule and buying based on price alone. Is cheapest usually best?

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Healthcare needs more e-patient Daves giving feedback.

Healthcare also needs to LISTEN to people like e-patient Dave, because they’re out there speaking to us all the time.

Amen, Dean.

Any information on the vendors of the carts shown above?