Tag: Toyota

Debunking Misconceptions About Toyota Production System: Video Insights From Nampachi Hayashi

tl;dr: In this post, Mark shares insights from a video featuring Nampachi Hayashi, a senior advisor at Toyota, discussing common misunderstandings about the Toyota...

“But TPS Doesn’t Apply to Us….”

Here is my latest article for "The Lean Post" and the Lean Enterprise Institute:

But TPS Doesn't Apply to Us...."

We hear that a lot.

"But patient...

Podcast #334 – Barry McCarthy on Toyota and “Development Organizations”

Joining me for Episode #334, all the way from Australia, is Barry McCarthy. Barry spent more than 15 years in leadership roles with Toyota...

When “Red Beads” Lead to What Looks Like Workplace Discrimination

Quite often, I used the famed "Red Bead Game" (a.k.a. the "Red Bead Experiment") that was made famous by W. Edwards Deming.

Here are my...

Podcast #333 – Jean-Marc Legentil and Marc-Olivier Legentil, The Toyota Kata...

My guests for Episode #333 are Jean-Marc Legentil and Marc-Olivier Legentil, father-and-son Lean consultants from Montreal, Quebec, Canada. They work together in the firm...

Podcast #332 – Jason Burt, on Being Coached by Toyota

Joining me today for Episode #332 is Jason Burt, owner of EHIP Consulting. Jason is a Lean consultant and business coach with an extensive...

Podcast #330 – Christoph Roser, His Grand Tour of Japanese Automakers

Joining me today for Episode #330 of the podcast is Christoph Roser, a professor of production management at the Karlsruhe University of Applied Sciences...

Toyota as a People Development Company: Lessons Beyond Lean Tools

When most organizations talk about Lean, they start with the tools.

When Toyota talks about Lean, they start with people.

On my last trip to Japan,...

Highlights from our Lean Event Tour at Toyota

Last week was our first "Symposium on Learning Organizations" where we brought together 40 people with diverse backgrounds in manufacturing, healthcare, IT, government, and other industries or professions together to learn from each other in a "PowerPoint-free zone."

In this post, I'll share some photos and reflections on our tour of the Toyota truck plant in San Antonio (TMMTX). The visitor center has been completely revamped from my last visit, just as the one visitor center I saw in Japan back in March had been redone.

#TBT: The Term “Lean Production” is Now 30 Years Old

Today is a throwback to a throwback, in a way. Five years ago, I blogged about how the term "Lean Production" was 25 years old...

A Look Back at Posts About Visiting Toyota Plants in Texas...

Today, I'll be touring the Toyota truck plant in San Antonio again, the plant known as TMMTX. I'm there with our "Symposium on Learning Organizations" group, all 40 of us. In this post, I share some pre-tour goals and share some links to previous Toyota plant visits (in Texas and Japan).

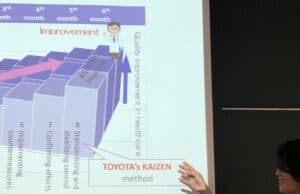

How Toyota Teaches the Toyota Production System in Some Japanese Hospitals

In the third and final part of this series, I share more about how Toyota teaches about TPS and TQM... and how they are sharing that approach with doctors and hospitals.