Last week, I wrote about the influence of Total Quality Management (TQM) on Toyota — in the past and the present, in Japan and beyond:

Today, to follow up on that, I'm going to share some excerpts from some material that was shared by a Toyota leader who presented at a hospital I visited earlier this year as part of the Kaizen Institute-organized Japan trip. The hospital didn't have a full-blown Lean or TQM program, but they were starting, i believe, by educating the doctors and medical students.

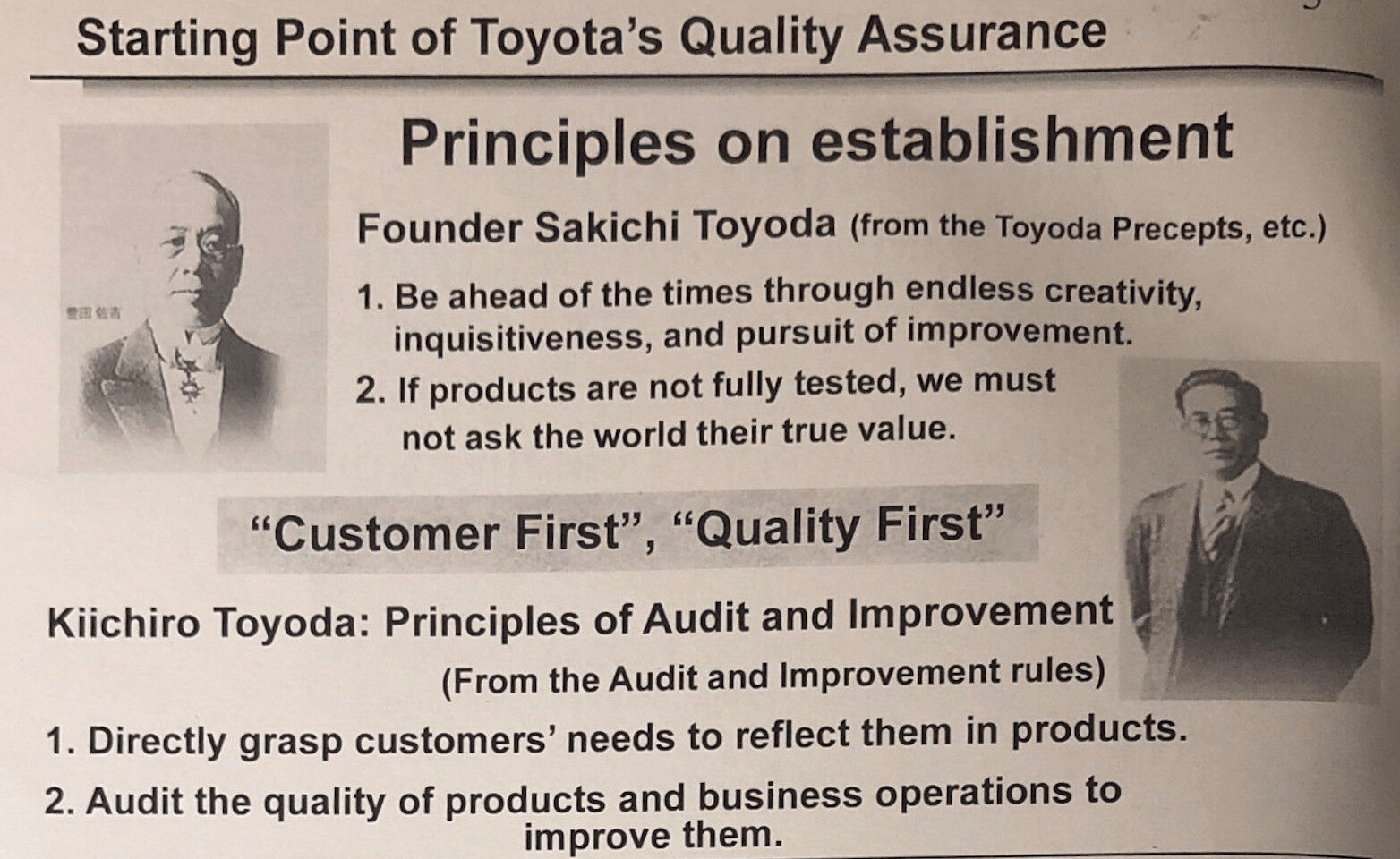

Toyota's focus on quality includes more than the “Jidoka” (built-in quality) concepts and methods of the Toyota Production System. Early Toyota leaders promoted the idea of “customer first” and “quality first.” Can this concept be applied in healthcare as “patient first” and “quality first?”

We need to do more than “audit” quality in either setting… we have to help ensure quality at the source through better processes, not just inspection.

As I shared on LinkedIn, with a page from this document, it really frustrates me when Lean Six Sigma people say things like “Lean is for speed… and Six Sigma is for quality.” Nonsense. TPS (and Lean) are about flow and quality, Again, see the Toyota website about that.

The Toyota person sharing these slides talked about Toyota's quality problems with the cars they started importing to the U.S. market in the late 1950s — “The car could not go uphill.” He also said:

“You could keep a fish in the trunk since it leaked so much when it rained.”

Toyota had some quality principles, but still wasn't delivering quality levels that were acceptable to the market, yet alone being anywhere near “world class.”

Toyota's “Basic policy” for going after the Deming Prize (which they achieved in 1965):

- To develop Toyota into a world leader by gathering resources from within and outside the company

- “Toyota learned from university professors,” he said, “So doctors can too.”

- To develop Toyota's reputation as a quality leader through an uncompromising focus on “Good Thinking, Good Products“

- To contribute to the development of Japan's economy by achieving a mass production system and low prices

It's interesting that they used the phrase “mass production” when “Lean production” (based on TPS) is considered to be the better alternative to mass production (a phrase that generally implies big batches, command-and-control management, etc.). I think Toyota was talking about “mass” as the need to scale and grow.

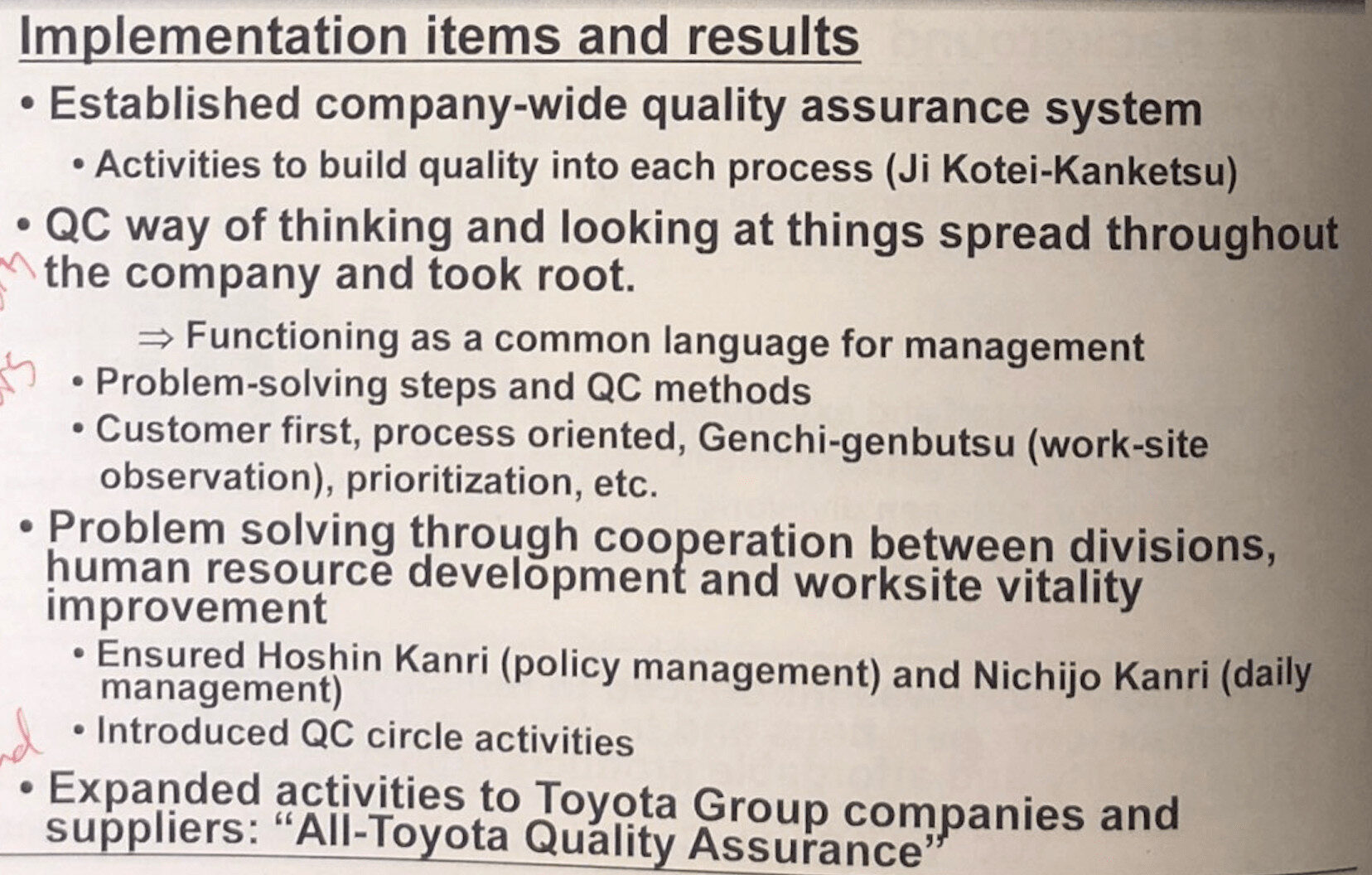

Toyota used Total Quality Control (later renamed Total Quality Management) as part of this strategy:

Read more about “QC Circles” in today's Japanese organizations.

The Toyota person said:

“The efforts to continue were profound. We are what we are because we continue.”

He added:

“The old mindset was ‘final inspection will find problems.' But some problems will get past inspectors.”

Relying on inspection was a characteristic of “mass production” as most people call it. Toyota, going back to its days of making weaving looms, focused on error proofing and other methods to prevent defects from being made.

Don Wheeler, in his class this week, keeps making reference to Dr. Deming's joking description of the Western approach to quality:

“I'll burn the toast, you scrape it.”

The Toyota leader talked about how “everyone has to participate” in quality improvement.

The Toyota person then talked about the “synergy between TQM and TPS.” It's not just American MBA graduates who use the buzzword of “synergy.” :-)

He said TQM “improves maintenance and Kaizen capabilities of production site leaders” and “promotes QC circle activities,” while TPS “makes quality failures visible.” Can hospitals handle “making failures visible” in a way that leads to constructive improvement?

It's all focused, together, on “fostering a corporate culture that is willing to tackle reforms” and “developing human resources to encourage creativity.”

And then, we get some Japanese words that might be new to you:

Monozukuri (manufacturing) cannot be achieved without Hitozukuri (human resource development).

That sounds like a different way of saying “we build people before we build cars,” as you often hear from Toyota people.

The Toyota presenter said, “The relationship between TPS and TQM is very complicated… TPS eliminates muda (through JIT and Jidoka). When you discover muda, how do you solve that problem? TQC provided the kaizen method.”

I'm surprised that they draw such hard distinctions between TPS and TQM. I would have guessed that it would all be combined into a Toyota way of operating. The presenter emphasized that “We learned TQM from professors… so doctors can learn too.” TPS was more internally created (but with input from outside influences). Maybe that's part of the distinction.

But current-day Toyota certainly seems to say that TPS and TQC are complementary and mutually supportive, as Tracey Richardson has been sharing on LinkedIn recently (see my previous post for that).

Lessons Leaders Can Apply Anywhere

Toyota's story shows that quality improvement isn't just about tools, whether in cars or in healthcare — it's about mindset, discipline, and developing people. By teaching doctors the same principles that helped Toyota earn the Deming Prize, this Japanese hospital is investing in skills that prevent problems, not just detect them.

If Toyota could learn from professors, and if physicians can learn from Toyota, then the opportunity is wide open for any industry to cross-pollinate ideas. The challenge for leaders is to create the environment — and the constancy of purpose — where those lessons can take root.

Where have you seen quality principles from one field successfully applied in another? Share your examples in the comments.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.