Over the years, many people have asked me some variation of the question:

“Why are my employees not embracing Lean?”

More often than not, the tone of the question is of blame… blaming the employees for not embracing Lean.

Sometimes, I get called in to visit an organization to help figure out the situation. A few times in a row, the answer was clear. Employees were not engaged with Lean and were not embracing the approach because Lean was misguidedly framed as all about cost cutting, as I've blogged about before:

Where Do Hospitals Get the Idea that Lean is Only About Cost Reduction?

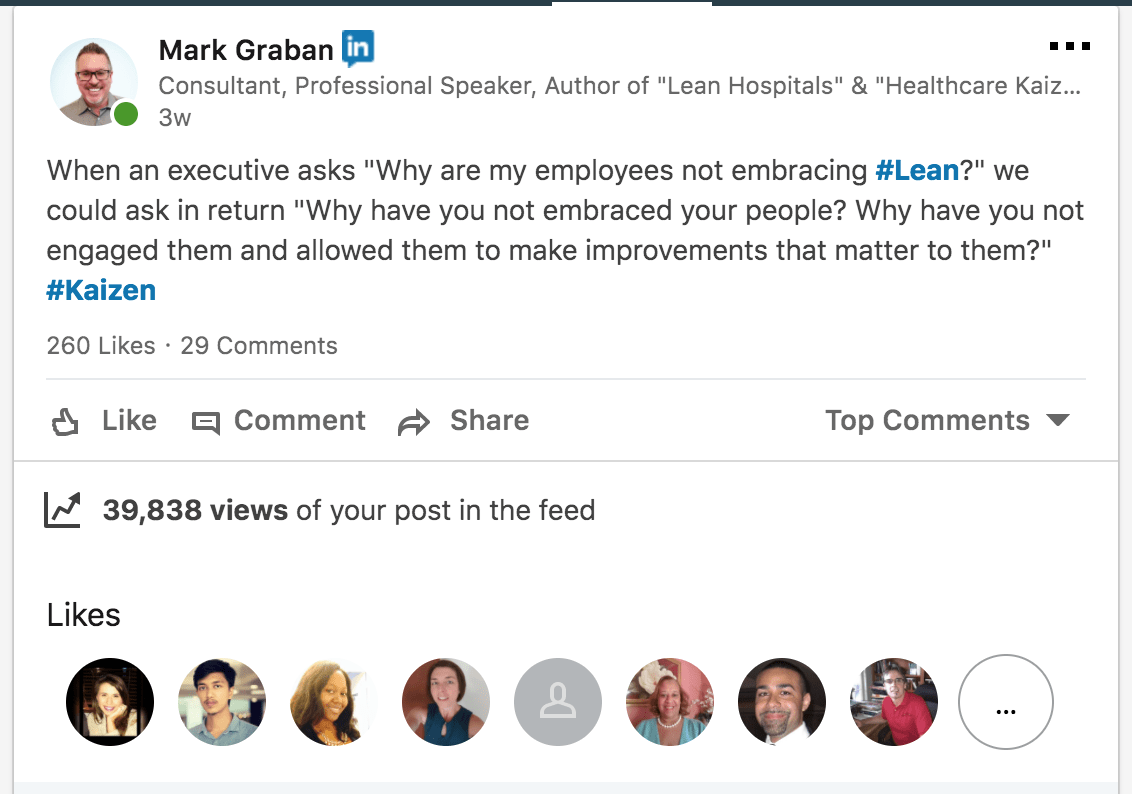

I put a short post on LinkedIn a few weeks ago about the question of employees not embracing Lean and got almost 40,000 views and quite a few comments. I'll elaborate a bit below.

I wrote:

When an executive asks “Why are my employees not embracing #Lean?” we could ask in return “Why have you not embraced your people? Why have you not engaged them and allowed them to make improvements that matter to them?” #Kaizen

I guess I could have asked:

- “Have you embraced your people?” and

- “How you engage your people and allow them to make improvements that matter to them?”

I could have asked those questions instead of assuming that the people asking the question of me do not do those things.

If leaders engage people and help them use Lean methods to solve problems that matter to them, they'll embrace Lean.

If leaders use Lean thinking and mindsets to better support their people, instead of just using tools, employees will embrace Lean.

If Lean is properly framed as a way to solve safety problems (for patients and employees), then employees will embrace Lean.

If leaders are servant leaders, lead with humility, and have the mindset expressed by former Toyota leader Darril Wilburn (“it's the responsibility of leaders to create a system in which employees can be successful”), then employees will embrace Lean.

Instead of blaming employees for not buying it, what can you do to be of service to them? To help them perform better?

There were many comments on LinkedIn and I invite you to share your thoughts below or on the LinkedIn post. Their comments are in italics and my comments are in plain text if I'm adding them.

Yes, Mark Graban! Employees don't have to agree with anyone or any approach. They may have to follow directions for a time. But, they don't have to agree. You can force compliance, but you can't force faith or trust. #Lean #CindyDiggs

Mark DeLuzio – Lean Pioneer and Architect of the DANAHER Business System

Actually, I wish there were more executives that would even ask that question!

True… how many executives are focused on spreadsheets and financial reports instead of even paying attention to the idea that employees might not be buying in?

George Harvey – Performance Excellence Facilitator at Martin Health System

I agree, but it may also depend on where the culture is and the trust gap that needs to be closed. How many times have their people been burned? How often has the organization lurched from one program to another?

Those are good questions and fall along the lines of what I'm saying about not blaming employees for not embracing Lean.

George Friesen – Business Practice Leader – Lean Transformations at St. Louis Community College

“Why have you not engaged your employees?” The answer, I believe, is fear. Many leaders find “letting go” as tantamount to not being a leader.

That fear and anxiety about a new leadership style is real. I think that's one reason why leaders need a coach for this Lean transformation (something that arguably starts with a personal transformation that can't be forced either).

Graham Canning – Managing Director at Lean FSL Associates Ltd

I'd also ask, ‘so have you ensured that they have time to make improvements, and provided a culture where mistakes can be made and learnt from?'. If the answer to either is no, then they'll never make a breakthrough. When are leaders going to realise that they must generate the conditions to be a ‘learning organisation' for lean to really deliver?

What would you add to the discussion?

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

It is not misguided if Lean is framed as “cost cutting” (cost reduction was one of the two original TPS goals) – PROVIDED it is clear that cost cutting is non-zero-sum (win-win) – that no employee will suffer unemployment as a result of cost reduction (or productivity improvement, the second TPS goal). If it is zero-sum (win-lose) cost cutting, then of course the framing for Lean is entirely wrong. Framing is also wrong anytime an exec says Lean is “all about” people, or lead-time reduction, or learning, or __________ (fill in the blank). The lack of precision in language is just one of numerous factors that result in employees not embracing Lean.

Cost reduction is a fine goal – a necessary goal, especially in healthcare.

In the modern world, “cost cutting” generally implies slash-and-burn tactics, layoffs, capacity reduction… and this is especially true in healthcare.

Cost reduction that comes as the natural result of waste reduction, process improvement, quality improvement… that’s nothing to sneer at, of course.

The root cause lies in the leader’s or executive’s mindset in regards to Lean. It is not wrong to seek cost reduction in Lean.

But, if all we want is a reduction in cost asap, why bother with Lean – just do a quick brainstorm and make a few slashes. This sounds like a cynical view, but I think any leader embarking on Lean must go through this rationale, to its end point. Only then can we truly appreciate its futility, and, then start to understand and appreciate the true, holistic purpose of Lean.

Why? Because getting our associates to embrace Lean, starts with the Leader embracing Lean, not for their own sake, not for a quick result, but for an ongoing, eternal journey to excellence for the organisation. This must be expressed in the leader’s own words, specific to the organisation’s challenge, rather than quoting from textbooks, experts, Sensei, etc.

The compelling argument has to be “we can’t keep going as we are”.

Like I said in my response to Bob, cost reduction is a natural result of Lean.

But, that’s different than “cost cutting” that focuses on cost first (or exclusively). It’s the type of cost cutting that makes people say, in jest, “We’ll cut costs no matter how much it costs us.”

You’re right that executives can do slash-and-burn cost cutting without hiring a Lean consultant. But, there’s a big market for cost-cutting snake oil salesmen… so there they appear. It’s especially egregious when the snake oil cost-slashing layoff consultants wrap themselves in the Lean flag.

In response to Graham’s comment above about giving people time to make improvements I was at a Shingo Silver medallion winner recently and they said they stop the plants for 2 hours a week to work on continuous improvement activity. It’s not a luxury that everyone has but shows tremendous commitment to lean and will surely help staff to fully embrace lean.

Factories can choose to shut down. A hospital can’t.

But, hospitals — individuals and teams — inevitably have slow times during the day or during the week in which they can choose to do continuous improvement.