A returning guest today for episode #280 is John Dyer, president of his consulting firm, JD&A, Inc., and a contributor for IndustryWeek.com.

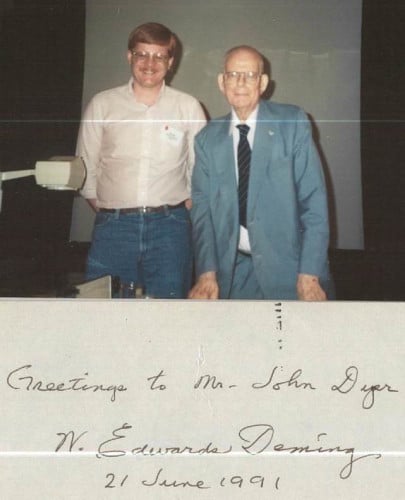

As we discussed in episode #229, John started his career at General Electric and later moved to Ingersoll-Rand, where he was VP of Operations for their Security and Safety sector. He also had the good fortune to learn directly from W. Edwards Deming, as he took the famed four-day seminar (that included the Red Bead Experiment) and was also invited to take the follow on course with a smaller group. You'll also want to scroll down to see the great picture that he posted on Twitter of him and Dr. Deming.

Today, our focus is that famed “Red Bead Experiment.” We'll talk about it, he'll share memories of Dr. Deming facilitating this, and we'll both share and discuss our reflections and our experiences with this, and the lessons learned. It's a pretty free-form conversation, and I hope you enjoy it as much as I did.

John continues facilitating the experiment and does so again next week. Tomorrow, I am facilitating the experiment as part of my “Better Metrics” workshop that I'm leading in Seattle through Catalysis. I'll also be doing this in June before the Lean Healthcare Transformation Summit (you can still sign up). And, of course, I'd love to come to your organization to do the workshop and help you with your approach to managing metrics, people, and improvement.

Streaming Player (Run Time 55:57)

For a link to this episode, refer people to www.leanblog.org/280.

For earlier episodes of my podcast, visit the main Podcast page, which includes information on how to subscribe via RSS, through Android apps, or via Apple Podcasts. You can also subscribe and listen via Stitcher.

PDF Episode Summary

You can download the PDF or read the summary below in this post.

- Low-res PDF (for reading on screen)

- High-res PDF (for printing)

Recent John Dyer Columns

What is the Greatest Impediment to Lean and Six Sigma Implementation?

The Dangers of Disguising Cost Cutting as Improvement

A Reason to Do Lean and Six Sigma Executives Will Embrace

Red Bead Videos with Dr. Deming & Others

Thanks to John for being such a great guest!

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Comments from LinkedIn

Sid Joynson:

I was an early attendee at the British Deming Association meetings, and joined after attending a weekend Deming workshop in 1990. I was much impressed by his teachings. On one of my early visits to Japan, I tried to discuss the red bead experiment with one of our Japanese instructors. He asked me why I had allowed red beads to enter the white bead box, and told me that I did not appear to understand the concept of zero defects through source inspection. He explained that the red bead experiment demonstrates the variability of the process. Source inspection removes the variability of the inputs to the process. If you ensure that only one colour of bead enters the box, there is no output variability to measure.

This is the basic thinking behind the quality section of the Jidoka element of TPS.

The most impressive example of this system I have experienced was on an assembly line for inlet manifold assembly in Japan. We were allowed to work on the line and challenged to produce a defective assembly. It was impossible to produce one, and we had some very talented people trying.

No statistical methods could have achieved this result.

Kenneth Stem:

The Red Bead Game is one of the most powerful teaching tools ever invented. You learn about management, about random samples (actually about how sampling plans virtually never include random samples), stable systems of variability and quite a bit about psychology.