This article caught my attention the other day, primarily because I like scotch, whisky (and whiskey and bourbon). The Japanese love scotch whisky and have long produced a product that's a variation of scotch — Japanese whisky (the lack of a standardized spelling for whiskey is an endless debate). I'll settle on “whisky.”

The article:

“Japanese Whisky Got a Lot of Hype, But Can One Bottle Really Be the Best?“

Now, you might not care about “the brownest of the brown liquors” (Simpsons reference), but there's an interesting detail in the article about the Kaizen mindset of continuous improvement.

From the article:

Japanese whisky makers also need to be methodical in how to go about exploring what combinations work without getting lost in the possibilities.

Japan's reverence and adaptation of statistical quality controls, quality design, and zero-defect strategies brought over by mathematician W. Edwards Deming to improve a devastated post-WWII economy pulled them out of a severe slump. It allowed the country to dominate car manufacturing and electronics by the 1980s.

I found hints of this larger cultural approach applied to the whisky making process, too. Mike Miyamoto, master distiller at Suntory, calls it “Continuous Refinement.”

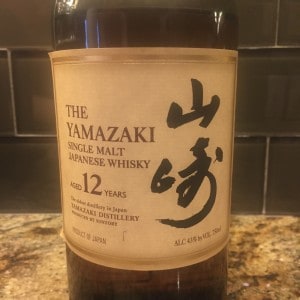

“If the Yamazaki you hold in your hand tastes the same in 10 years, we have failed,” he once told me. This means tightening and perfecting occurs every moment in the process, as does buffing out defects and exploring new designs and methods. Changes for the better are encouraged, both in taste and in process.”

There are many interesting thoughts there. One is the ongoing influence of Dr. Deming (which I'm guessing was specifically mentioned to the writer, as Dr. Deming is still highly regarded and talked about in Japan, including in hospitals).

I find it interesting that Dr. Deming pooh-poohed the idea of “zero defects” as something that was perhaps an empty slogan, something that would be a huge problem if we didn't have a method, like error proofing. And, he was right that zero defects wasn't enough in meeting customer needs and being a successful business.

The other is, of course, the idea of continuous improvement. This can apply to both process improvement and product development. The “Lean Startup” methodology emphasizes the continuous refinement of products and services – lots of iterations and cycles of learning. Everything can be improved.

“Changes for better” are encouraged – that's Kaizen. One literal translation of the Japanese word Kaizen means “good change” or “change for the better.”

Listen to Mark read the post, along with an audio clip from The Simpsons (subscribe to the series):

Many whisky producers aim for an incredibly consistent product over time. People like the flavor profiles of a certain producer and the master distiller will blend many different barrels and ages of whisky together in a batch to produce a taste that's consistent over time.

Yamazaki and Suntory take a different approach:

If the Yamazaki you hold in your hand tastes the same in 10 years, we have failed... Share on XNow, that improved whiskey's not going to be so different that it suddenly taste like blueberries or tequila, but he makes a good point that they're going to try to get better rather than just be consistent.

In your own work, how you find the balance between maintaining proper consistency in your product or service, while also being sure to continuously improve and evolve? Is “the way it's always been” good enough for the market and your customers or do you have to always strive to get better?

Volunteering at Garrison Brothers

I'm spending the day today as a volunteer at Garrison Brothers distillery in Hye, Texas (west of Austin and about an hour north of my San Antonio home). It's not really as noble as volunteering for a non-profit, but it's a heck of a lot of fun.

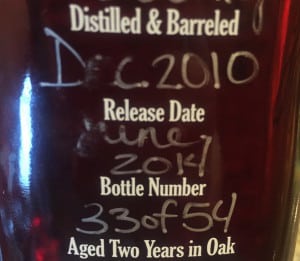

Garrison Brothers is a small “craft” producer of bourbon-style whiskey (it's legally “straight bourbon whiskey,” even though it's not made in Kentucky). They have been on the market for just a few years and they do two “releases” a year – in the spring and the fall. They certainly produce to a consistent style, but the bourbon evolves and changes with each release.

The owner and the master distiller think each release gets better, as they have aged some of the whisky longer and as they've gotten better at their craft. But, everything in the Spring 2015 release should taste consistent. If you have two different bottles, it should taste the same… but probably different than the Fall 2013 release. That's not “bad variation” (trust me, not all variation is bad!), that's evolution and continuous refinement.

Now, they also produce and bottle a “single barrel” product, where a single barrel of aged whisky is selected because it tastes great without any other blending. They might get just 54 bottles from a small barrel. Each barrel tastes different and that variation from barrel to barrel is part of the charm and appeal of such a product.

I'll be volunteering to help with the bottling process, as shown in some pictures from a previous trip there. I'll try not to have my “Lean consultant” hat on too much, but as a participant in the process, I'm free to bring forward Kaizen ideas and other Lean methods that might be helpful.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

From today’s WSJ:

“Jim Beam’s New Japanese Owners Remix Bourbon Brand”

Since Jim Beam (from Kentucky) was bought by the Japanese spirits company Suntory, they are being introduced to Kaizen.

While Yamazaki applies Kaizen to their product, Jim Beam might be more comfortable applying Kaizen to business functions and the process around making bourbon. Jim Beam can learn from the Toyota plant in Georgetown, Kentucky perhaps?

If the product isn’t broken, don’t fix it?

Looks like you had a great time dipping that bottle Mark!

[…] I wrote a blog post about the intersection of two things I like a lot: Kaizen and whiskey: “Why Kaizen is an Important Differentiator for Japanese Whisky.” Yeah, the spelling of whiskey/whisky isn’t standardized […]