Back in September, I wrote about our most recent “Lean Coffee” gathering in San Antonio, where people from different healthcare organizations talked about their improvement efforts.

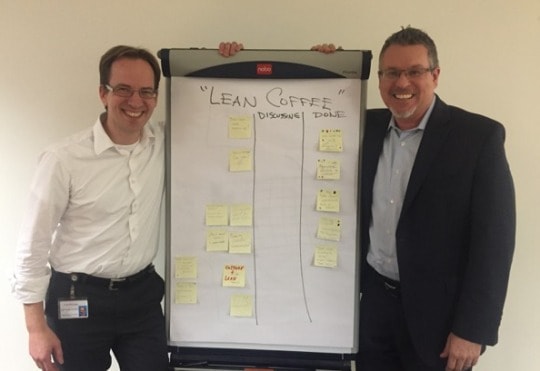

As part of my visit to The Netherlands this week, Marc Rouppe van der Voort (pictured below with me), arranged a gathering of healthcare improvement professionals who participate in their national Lean healthcare collaborative network.

Being a group of ten people with shared interests, we decided to facilitate our discussion in the “Lean Coffee” format. Pictured above is our board as it looked when it was completed. We talked about five different topics that the group proposed and voted on… for either six minutes or 12 minutes depending on the group's mood and willingness to continue.

As I also saw and heard during my three hospital visits (“gemba walks”), the types of challenges people face and the questions they ask are VERY similar to what people are asking and talking about in San Antonio, across the U.S. and Canada.

What “Lean Coffee” topics did we discuss here in Holland?

- Changing to Lean leadership from old management practices

- How do we motivate people to improve?

- How does “kata” or other small improvements (kaizen) lead to measurable results?

- Using visual management to improve, how do we introduce it?

- “Our CEO supports Lean” – what should that mean?

For topic #2, I posed that in a provocative way, also asking “can we motivate people or can we just get out of their way, assuming they already want to improve?” I think it's better to think about creating an environment where Kaizen can happen — doing things (or NOT doing things) that encourage improvement rather than feeling like we have to force it.

I had also proposed topic #5 and we had great discussion. What does “support Lean” mean from a CEO? That they tolerate Lean's existence? That they say good things about Lean? That they hire a Lean department? Or does it mean they play a very active role in modeling Lean leadership behaviors and concepts, directly participating and leading Lean?

Topics that were proposed but NOT selected were:

- Let the doctor connect with patients… how does Lean apply in the exam room?

- Shingo Prize adapted to Dutch healthcare?

- Does Lean work “bottom up?”

- How to connect initiatives?

- Are “quality circles” an underutilized approach?

- Culture or Tools (or both)?

- How to spark a Lean culture?

- How to keep focus on patients during times of financial pressure?

- Push vs Pull application of Lean (how to create “pull for Lean?”)

Hospitals here are certainly facing financial challenges. Healthcare is too large a piece of the Dutch GDP (12%+) and it's increasing too fast. Hospitals have laid off employees to try to address the pressures on their payments. Patient volumes are lower as people have to pay a larger share of healthcare expenses under their new insurance plans (mainly private insurance, like the U.S., but all non-profit, unlike the U.S.).

The high-level challenges seem familiar, eh?

The detailed operational challenges are extremely familiar too.

The good news is that we can learn from each other instead of focusing more on how we're different…

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Hi Mark

Ultimately CEO’s have to model the right behavior for success to occur, because if they don’t the managers people see daily won’t either. Toyota workers will rarely if ever see their CEO in their lives with Toyota, but they will see the men and women that run the plant, and those people are going to model what they learn from those above them. CEO support is living the Lean walk, not just talking or funding it.

Good culture tends to get people to want to contribute and support improvement, whether they come up with an idea or not. If you create a culture that expects and allows improvement, some people will come up with ideas, but for an idea to work other have to not try and sink it. It is not just getting people to come up with ideas that is key, but getting to a culture that ideas are tested and tried with good one being added and bad ones being dismissed, not because of tradition, but because of test results.

You’re right that Toyota employees rarely see the CEO… but in healthcare the CEO of the hospital might have as many employees as an auto industry plant manager or the president of the Toyota San Antonio factory.

But you’re right that behaviors (both good and bad) “roll downhill” as they say.

I’m going to be able to release some videos soon about Kaizen at Franciscan St. Francis Health. The employees say frequently that their managers don’t just ask for their ideas but they let them TEST ideas into practice. Try it and see how it works… then evaluate.

Robert is spot on!! I have retired but towards the end of my consulting career I would not work with a company unless the CEO agreed to get down on the floor and talk to people about what is happening, their projects, etc. And attend one series of seminars. Otherwise, it was usually a waste of money and my life’s time.

WE also continue to have the difficulty of management change. I’ve seen so too many great improvement efforts abandoned when new management took over. Even where the work was deeply inculcated in the very fabric of the company. Wiremold (Lean) and Proctor and Gamble (Deliberate change) come to mind. One solution is for those responsible for replacing the CEO ensuring that s/he fully ‘groks’ Lean and agrees to keep it humming.

Thanks, Paul. I think it’s important for the CEO (or other leaders) to come visit the shop floor and mainly give thanks and recognition for people’s improvement efforts. Even the most benign questions can seem like criticism, so leaders have to be careful. “Why didn’t you consider _______?” might be an honest and reasonable question, but a question like that can really sting. So I also emphasize not just being out there on the floor, but also focus on behaviors that add energy to the system rather than inadvertently demoralizing somebody.