It's sometimes said (and I believe this to be true) that “100% inspection isn't 100% effective” (it seems like Dr. W. Edwards Deming might be the origin of that quote).

This is true in healthcare, if we talk about inspecting medications to make sure the wrong med hasn't been sent from the pharmacy or in other situations. This is also true in publishing, that inspection (aka editing) isn't 100% effective either, when we rely on people to catch or respond to errors. Someone once told me that every book published will have a number of typos, defects, and errors.

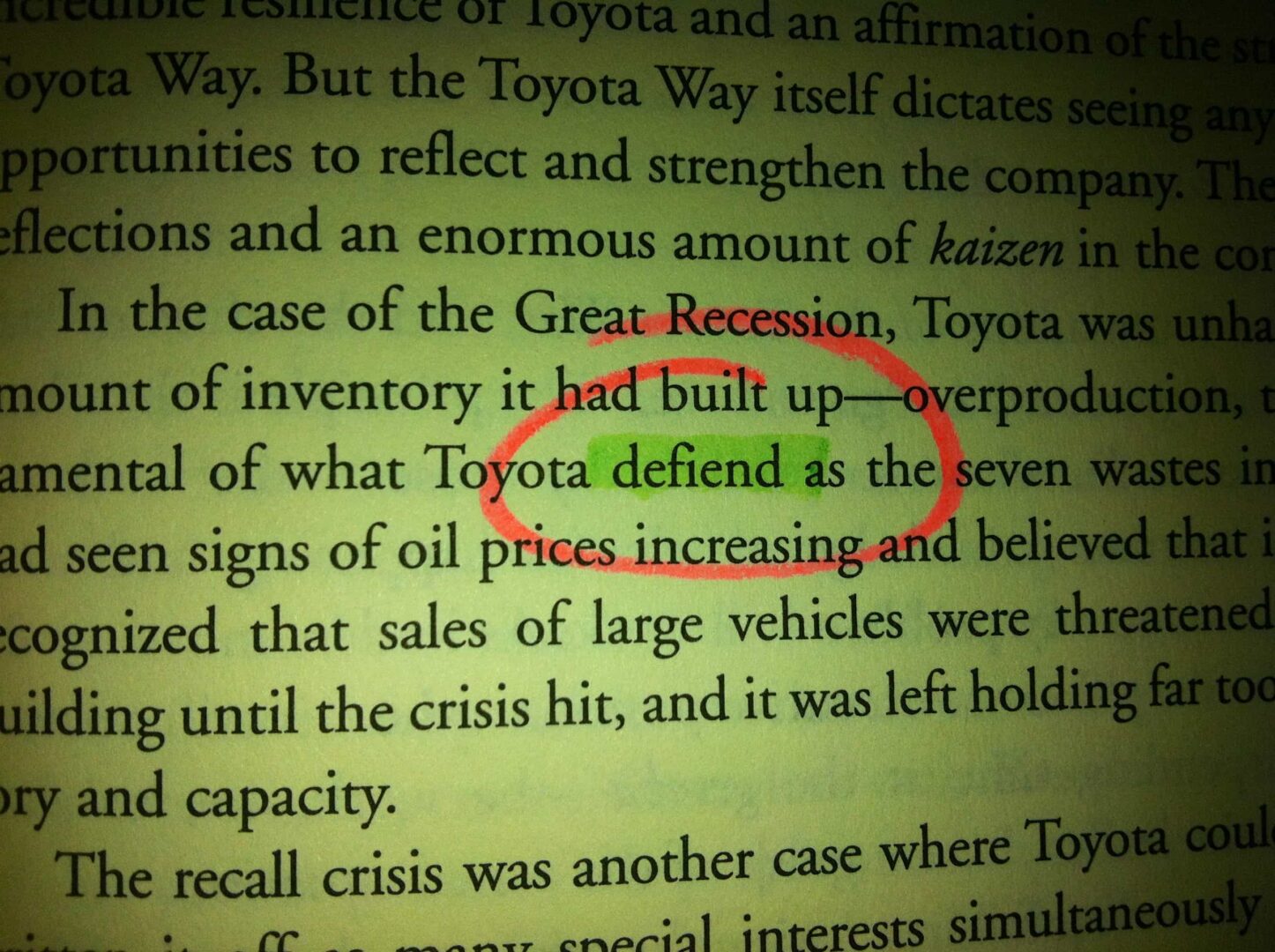

In particular, there was a typo in the prologue to Professor Jeffrey Liker's latest book, The Toyota Way to Lean Leadership: Achieving and Sustaining Excellence through Leadership Development, on page xxi:

The word “defiend” isn't even a word. My browser's (Safari's) built-in spell check catches it as a mistake, even. So, how does that get through into a book from a major publisher?

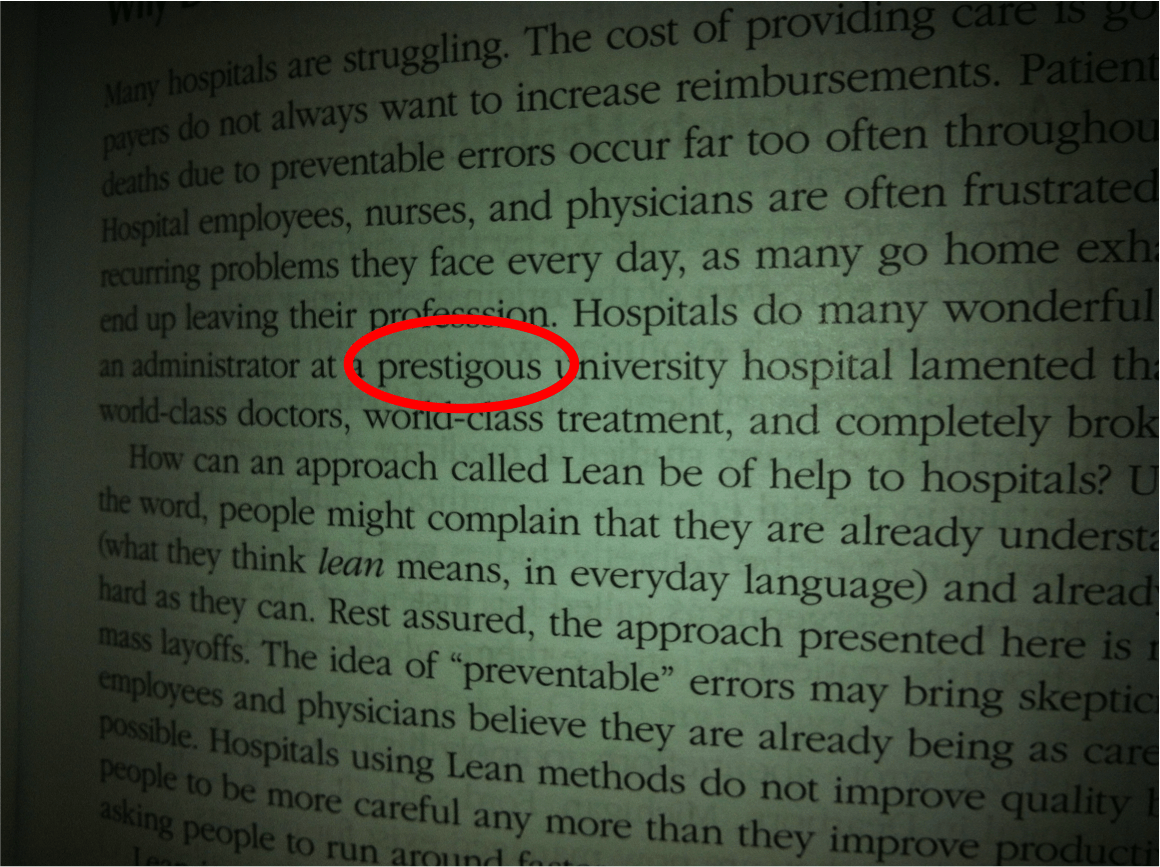

There was a similar problem in the first edition of my book Lean Hospitals (the 2nd edition is now in stock at Amazon.com as of today, by the way).

On page 1 (yes, the very first page) of the first edition was this spelling error:

“Prestigous” instead of prestigious.

I'm not sure how that got past my Microsoft Word spell check and I'm not sure why the editing process didn't catch that. Multiple human readers in addition to software., yet the spelling defect got through.

The error even continued until I caught it during the final stages of editing the 2nd edition.

It just goes to show we can't rely on inspection, or even multiple inspections, in critical healthcare processes. Nobody dies from a spelling error in a book… but a typo or preventable error in healthcare can have a far worse impact…

If you're reading the 2nd edition (or 3rd edition) and see any typos or errors, let me know, as those can be corrected in future printings…

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

defiend – The act of removing fiends from an area ;)

Ha. Not according to Webster’s. :-)

But if you google “defiened,” you get an essay titled:

“Can hapinness be defined?”

I guess happiness does not require good spelling?

Ahhh Mark.

I love irony.

“Multiple human readers in addition to software., yet the spelling defect got through.”

Hope all is well with you.

Jeff

Although 100% visual inspection is not 100% reliable and 100% measurement inspection is about 95% reliable, 0% inspection with capable processes (Cpk = 1.33) is only about 50% reliable at the end of thee month in most western factories!

One of the best articles concerning 100% inspection is the one provided by Toyota’s Dr. Kitano:

LINK

What I don’t understand is how American Quality Consultants got is so wrong, and how Japan’s Nuclear Quality Experts failed the entire country!

I suspect what the author means is 100% inspection by humans is unreliable. However, 100% inspection using autonomous systems is entirely reliable and forms the basis of poke yoka. Moreover, 100% inspection – testing, checking examining – can also be used to match sub-assemblies in Kanbans, which otherwise would require huge sums of money to be invested to achieve a natural capability. Further information on this topic can be had from Kitano’s seminal article ‘One-by-one confirmation or my own article ‘Dependent and independent process steps.’ (google)

Great point. We can error proof a process.

I should have been more clear, but I was writing about human inspection. Hospitals tend to rely too much on human inspection in processes, something that’s not 100% effective.