This article is based on my recent Catalysis webinar, “Lean Lessons from Japan: Mindsets, Culture, and the Challenge of Speaking Up.” The session was part of their ongoing learning series, and the recording will be available soon through Catalysis and their YouTube channel, I believe.

Since 2012, I've been fortunate to travel to Japan six times with different study groups. My first trips were with the Kaizen Institute, later with Honsha, and most recently with Katie Anderson's tours. Each time, I've gone not as a cultural expert, but as a learner — observing, listening, and trying to make sense of what I saw.

By the way, I'm now organizing new healthcare-focused trips to Japan — come join me!

One lesson has become clear: Japanese organizations are not magically Lean. They're working at it, just like we are. That realization might be both humbling and reassuring.

Hear Mark read this post — subscribe to Lean Blog Audio

Lean as a Product of Mindsets

When we talk about Lean, especially in the West, we often fixate on the methods, including:

- 5S,

- Kanban

- A3s

- strategy deployment

These tools matter, but what I've learned in Japan is that the methods emerge from something deeper. They are expressions of mindsets and beliefs about people, work, and leadership.

Take the idea of long-term thinking. Ina Food, for example, practices what they call “tree-ring management.” They post a 100-year calendar on the wall to remind themselves that growth should be steady, layer upon layer, not explosive or short-sighted. Read more about Ina Food in this free journal article.

Their chairman put it memorably:

“Profit is like excrement produced by a healthy body. Nobody's goal is to wake up and produce excrement — it's just the natural result of living and doing things well.”

That way of thinking leads directly to management practices. Because profit is seen as the byproduct, leaders resist short-term cost-cutting, especially at the expense of employees. When times are tough, senior executives reduce their own pay before they ask staff to sacrifice. When conditions improve, frontline employees see their pay restored before executives do.

At Toyota, leaders frequently say their company is a “people development company.” That's not a slogan. In 2002, Toyota distributed a booklet, Developing People, to reinforce that its competitiveness rests on human resource development at every level. Improvement is not just for SQDC outcomes; it is the vehicle for developing problem-solving skills and scientific thinking. The methods — A3s, PDCA cycles, small Kaizens — are how they do that.

Culture: The Double-Edged Sword

Westerners often assume that Lean should be easier in Japan, given its origins. The reality is more complicated.

There are aspects of Japanese culture that align beautifully with Lean. Standardization, for example, is deeply embedded. You see it in something as simple as gift wrapping in a department store. If you tell a clerk the purchase is a gift, you'll get wrapping that is consistent, precise, and almost artistic.

You see it in the way commuters queue for trains, lining up neatly in marked lanes instead of crowding the platform. Compare a Japanese group to our group of Westerners.

There is comfort with kata — routines and patterns — that support consistency and discipline.

But there are also cultural dynamics that make Lean harder. Chief among them is the reluctance to speak up. There's a common saying:

“The tall blade of grass gets mowed.”

It's a reminder that conformity is prized, and those who stand out risk being cut down.

This dynamic shows up in workplaces. In many Japanese companies, it is not considered acceptable to challenge your boss or disagree openly. Silence is the safer path. Communication tends to be indirect. Instead of a flat “no,” you might hear, “It would be difficult.”

The result is that speaking up about problems or improvement ideas doesn't come naturally. One factory leader acknowledged it plainly: “Some are afraid to express their opinion.” Another said: “

Highlighting problems doesn't come naturally to Japanese people.”

The cultural “relief valve” is after-work drinking with colleagues and bosses. In that informal setting, people often feel free to say what they really think, with an understanding that those words won't be held against them. But that freedom doesn't always carry back into the workplace.

For Lean to thrive, companies like Toyota have had to deliberately counteract this tendency. The andon cord is one example — not only a technical device for signaling problems, but also a cultural mechanism that makes it easier to speak up. Pulling a cord is less confrontational than raising your voice. The method serves the mindset: it creates a safe way to surface problems without violating norms of harmony.

Related Blog Post:

Healthcare in Japan: Not Ahead, but Learning

When American hospital leaders first visited Japan in the 2010s, they expected to find advanced Lean practices in healthcare. What they found instead was surprising: Japanese hospitals were behind.

Most hospitals were focused on TQM — Total Quality Management — which never faded away in Japan the way it did in the U.S. In 2012, one Japanese hospital executive told us candidly:

“Many Americans came to Japan, but there was no medical example at that time.”

That has changed over the past decade. Japanese hospitals are now working directly with Toyota mentors and, interestingly, learning from American health systems like Virginia Mason, Mayo, Brigham & Women's, and Seattle Children's. Just as Americans go to Japan to study Toyota, Japanese hospitals have visited the U.S. to study our hospitals. Planes fly in both directions.

But the challenges are familiar. Hospitals can be just as disorganized as in any other country. One visit showed an OR area without a sterile core. Another had messy storage rooms lacking 5S.

Suggestion boxes — labeled “honorable opinion boxes” — existed, but often suffered the same shortcomings as they do elsewhere.

Some hospitals are changing their philosophies to emphasize people-first approaches. Nerima General Hospital states explicitly that its mission is to make employees happy to work, patients happy to be treated, and the community reassured by the hospital's presence. One CEO went even further, admitting bluntly:

“I'm not a liar, so I don't say ‘patients first.' Lots say it, but I've never seen anybody who really thinks that way. We are not saints — we are ordinary people, so self comes first.”

His point was not selfishness, but honesty: if staff are satisfied and supported, patients will be better served.

Kaizen: Small Steps, Big Impacts

Perhaps the most encouraging lessons come from Kaizen.

At one hospital, a pharmacist described their team before Kaizen as “like mice running around the pharmacy.” Through many small changes, they cut medication preparation time by 60%. At another hospital, Kaizen contests celebrated staff participation, not cost savings. Data showed that most improvements focused on making work easier, with only a small fraction tied directly to costs.

Manufacturers showed similar patterns. I visited one that kept binders filled with thousands of single-page Kaizen reports. Leaders admitted: “We were not always a Kaizen company.” Culture had to be built intentionally.

One of the most memorable quotes came from Dr. Shuhei Iida, CEO of Nerima General Hospital:

“If you keep doing Kaizen, you will get innovation.”

It's a reminder that innovation is not only the product of moonshots or big bets. It often grows out of the steady accumulation of small, daily improvements.

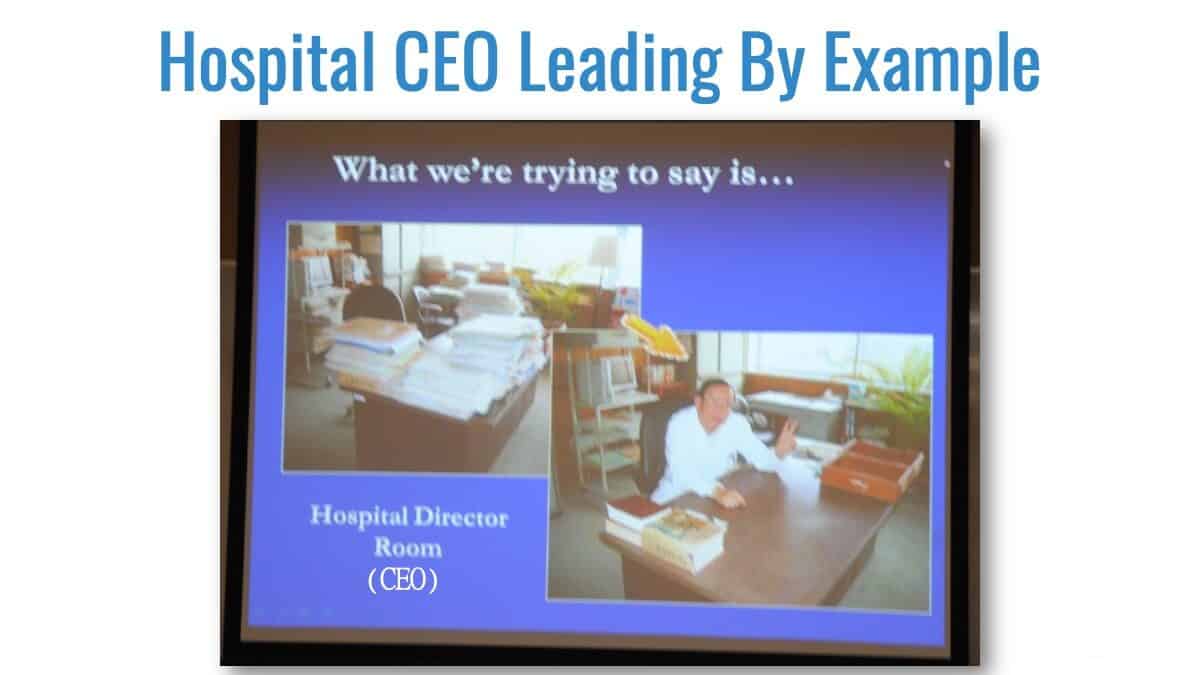

Leadership by Example

Across both industries, one thread stands out: leaders model what they expect.

At Nerima General Hospital, the CEO began 5S in his own office before asking others to do the same. He also participates in biannual internal audits. Another hospital CEO joins staff in hands-on improvement work.

At a manufacturing company, the president begins each day by scrubbing the floor with a bucket and rag alongside employees.

These are not stunts. They are signals. They show that improvement is not delegated; it is owned. As one executive put it,

“The role of the leader is to set the vision — that cannot be delegated.”

Lessons for Us

So what should we take away?

Lean in Japan reinforces that methods follow mindsets. Tools like A3s, 5S, and Kanban are important, but they are effective only when built on respect for people, long-term thinking, and a commitment to developing capability.

It also shows that speaking up is not natural, even in Japan. Psychological safety must be actively cultivated. The andon cord, incident reporting, Kaizen contests — these are all systems designed to counteract the human (and cultural) tendency to stay quiet.

And finally, it reminds us that Kaizen is the bridge to innovation. If we wait for the big leaps, we'll miss the steady gains that build capability and confidence. If we encourage small daily improvements, the breakthroughs will come.

Closing

Every trip to Japan has underscored this paradox: Lean is both easier and harder there. Standardization and order come naturally, but speaking up does not. That tension is exactly why Japan is such a powerful place to learn.

The lesson is not to copy Toyota or any other company. It's time to ask ourselves:

- How do we make it easier for people to see and solve problems?

- How do we make it safe for them to speak up?

- How do we ensure improvement is part of daily life, not a special project?

Because in the end, Lean is not about tools or templates. It's about creating the conditions where people can contribute, learn, and improve — every day.

And that's a universal challenge.

Join Me in Japan: Learning Lean at the Source

I often say that Lean isn't just about tools — it's about mindsets, culture, and leadership behaviors that bring those tools to life. There's no better way to see that in action than by experiencing Japan firsthand.

Since 2012, I've had the privilege of leading and participating in multiple study trips to Japan. Each time, I come away with fresh insights into long-term thinking, respect for people, and how daily Kaizen can build innovation.

Now I'm excited to invite you to join me for our upcoming Lean Healthcare Accelerator Experience in Japan.

What to Expect:

- Visits to world-class manufacturers, including Toyota, to see Lean principles at their source.

- Time inside Japanese hospitals to learn how TQM and Lean are being applied in healthcare.

- Rich discussions with Japanese leaders and executives about leadership, culture, and people development.

- Reflection and networking with fellow healthcare and improvement professionals from around the world.

This isn't tourism with a Lean flavor — it's a true learning immersion. You'll come away not with a list of tools to copy, but with a deeper appreciation of the mindsets and behaviors that make Lean sustainable.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.