Mark's Note: Today's post is written by Steve Hoeft, the SVP, Chief of Operations Excellence at Baylor Scott & White Health (BSWH) here in Texas. This is his first written contribution to Lean Blog, but you might remember him as a guest in episode #226 of my podcast, where he and co-author Dr. Bob Pryor talked about their book The Power of Ideas to Transform Healthcare: Engaging Staff by Building Daily Lean Management Systems. Steve is also previously author of another book I really like, Stories from My Sensei: Two Decades of Lessons Learned Implementing Toyota-Style Systems

. Both of those books are recipients of the Shingo Research Award. You can, if you prefer, download this article as a PDF.

“The only person who likes change is a baby with a wet diaper.”

– Mark Twain

In my years serving as continuous improvement leader and consultant for some great organizations, I've discovered something consistent: Improvement will not happen on its own. Every organization needs what might be called a forcing mechanism, or what I call a “make me” (do it). I don't mean that in a mean or manipulative way. I use the phrase to mean some forced discipline or a required activity that motivates me to do the harder thing in the short term, in the name of some longer-term benefit. Rather than using a lengthy descriptor like “leader-motivating-systems-that-force-new-disciplines-creating-habits-toward-transformational-change,” I'll just use “make me.”

It is harder to continuously encourage and make improvements than it is to do nothing. If a leader “coasts” and does not ask staff for improvements, it may be an easier way to get through today. But, it robs people of their innate desire to be part of a team or something bigger than themselves. We all have the ability and brainpower to make things better – especially at work.

Some organizations do the right things for the right reasons. I have always admired Toyota for consistently operating by their principles – not just during the tenure of a CEO, but over decades! Most organizations need motivation or what some call a “nudge” to do what is harder in the short-term to achieve long-term success. Yes, just like dieting. What if leaders could build a system that acts like a personal trainer?

3 Definitions: Why is Change So Hard?

Wikipedia defines a forcing function as any task, activity or event that forces you to take action and produce a result. If we allow the use of the word force in a positive way, it becomes like a motivational personal trainer to help you overcome obstacles and make necessary change until they become valuable habits for us. So, what “forces” you to improve every meaningful measure in your department, division and company?

Wikipedia also defines inertia as the resistance of any physical object to any change. In the book The Power of Ideas to Transform Healthcare (pg. 333), I bemoan how entropy works against us daily. Things generally go from an orderly to a disorderly state, unless energy is put back in to restore it to the original state – just look at your teenager's room! Linking the definitions, we need a forcing function or a make me to help motivate staff and leaders to apply energy (ideas, experiments) back into the system – to maintain and improve! This will be critical over the next ten years, as healthcare continues to transform in a major way.

“People don't change until it becomes too uncomfortable to remain the same!”

– Gary DeSalvo, Temple Bible Church

This article focuses on the need for an improvement forcing mechanism organization-wide. But, it helps to look at specific, smaller ones first.

Example 1:

A small example of a make me was my health insurance plan in the 1990's at Engineering Services Group. We had great benefits, but health costs were soaring. The new plan allowed the same low premiums, but only if staff kept their Body Mass Index (BMI) under 30. If their weight/BMI at a doctor visit exceeded the limit, the staff member had six months to reduce it… or else out-of-paycheck premiums nearly doubled. It hit us in the pocket book! And, yes, it forced me to make changes, allowing my intrinsic desire to be healthy to overcome my not-today resistance. A positive secondary effect on our staff was awareness of health costs, as well as the importance of our own health!

Example 2:

A small work example of a make me with multiple good effects was at BSWH. To encourage the next step in our culture of continuous improvement journey – having an organization full of self-sufficient problem solvers – the President of Operations set a goal for each site to do multiple A3 Waves (problem solving teams grouped together for efficiency and camaraderie). The first good effect was that tough problems got solved. The next better effect was the start of a root cause problem solving culture – like Toyota's principle to always stop-and-fix (versus hide it)! But, by far, the best effect was that it became “OK to identify and elevate all problems.” Problem identification was encouraged by leaders.

Example 3:

Another good make me at BSWH was setting a goal that all top operations executives must go to Gemba and do an equal share of layered audits with our 1000+ huddle leaders – coaching at all boards every quarter. Directors and managers did most of the audits. The goal was a strong reinforcement, reward, and priority for top leaders. A good effect was that staff felt leaders cared about their improvements and made them a priority. The next better effect was that executives were able to align measures and actions to their goals and strategies (the weekly part of Hoshin Kanri). But, by far, the best effect was that leaders started coaching other leaders in their organizations. Coaching creates great opportunities for two-way conversations. And, the leaders were building their system of improvement together. It was not someone else's system!

4 Reasons You Must Build Make Me Systems

First, there must be a “vehicle” or a way for your staff to make improvements. What is yours? Most organizations do improvement projects of various kinds. The majority hire black belts or professional facilitators and they manage the projects. These professionals are assigned to make improvements full-time, so they implement many of their own ideas, instead of soliciting and facilitating the ideas of the people doing the work. Some of these changes ‘stick,' and some do not.

We found this improvement-through-projects only approach does not sustain very well. Leaders in these organizations use the tools that their black belts or consultants have learned, which vary considerably. But, staff understand little of the what and why for key changes.

The main limitations of a project approach is that only about 5% of the workforce can be actively involved each year. Most projects pull staff away from their jobs to train and analyze processes. In healthcare, it is very difficult for any staff to step away from their daily work for projects. In fact, project teams are often made up of staff who are “available,” rather than the best. But, what do the other 95% of staff do? Do their ideas and brainpower count for anything?

If an organization limits itself to the ideas of just a few staff or professionals, they have chosen to slow their improvements and not tap the ideas of the smart people they hired.

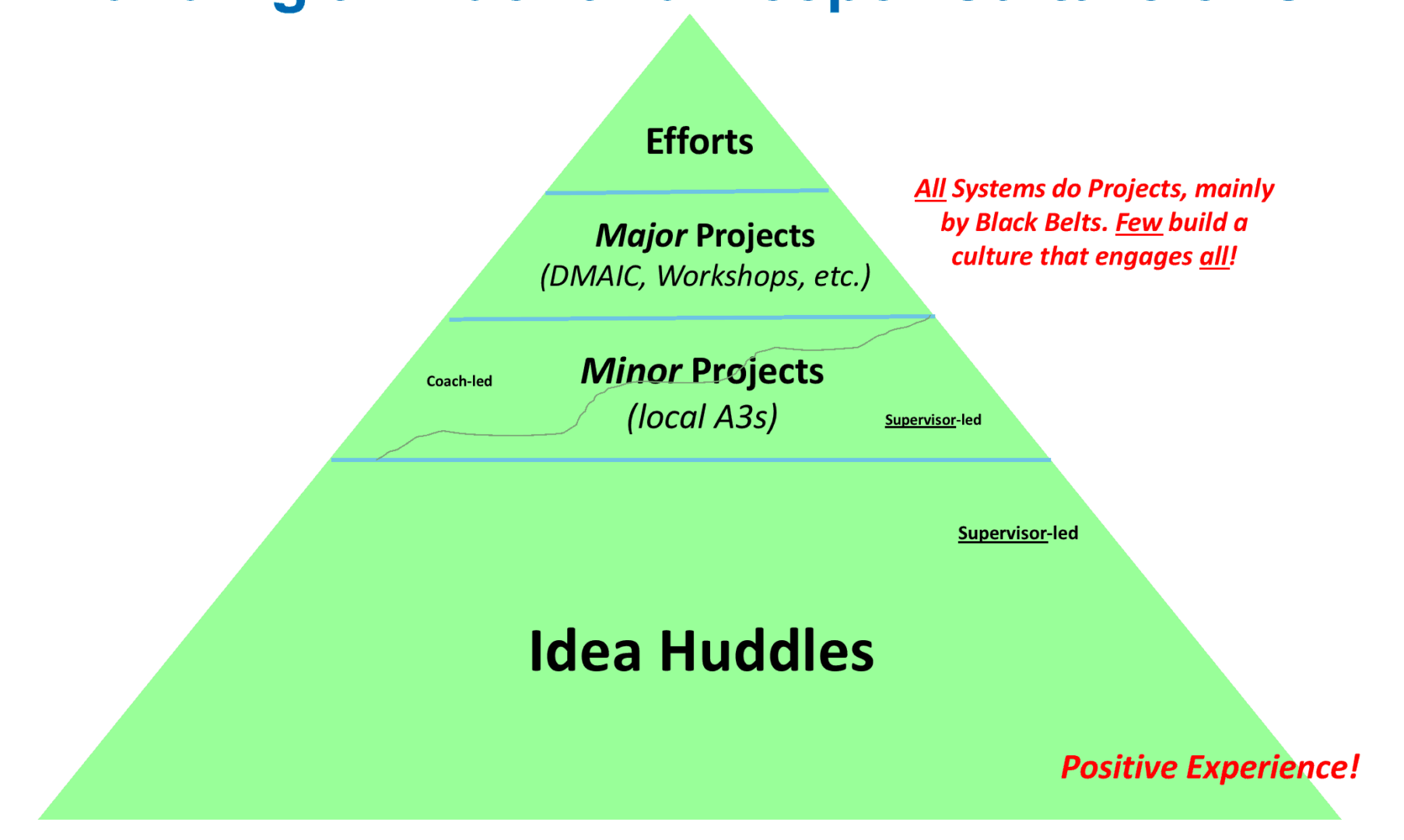

Idea: Our suggestion is that you develop an improvement operating system that maximizes the lower part of the pyramid in the graphic below.

The foundation of the pyramid is wide because it represents both the number of people involved daily and the number of individual ideas for Plan, Do, Check, Act (PDCA) experiments. In great organizations, only about 10% of ideas implemented annually come from major projects – the smaller third layer up in the diagram. The majority of ours are tried out as staff do their jobs daily. So, how many do your staff implement daily?

Our operating system foundation starts with every day “idea huddles,” supported by leaders. All staff huddle daily, if possible. Their huddle board contains trend charts of four to five key input metrics that are most important to staff, along with analysis (Why), and their ideas or experiments. In an Idea Huddle (usually 15-minute pre-shift stand-up), the leader picks a single metric, problem or waste on their huddle board and asks the team, “What can we do today as a team to close this gap?” If the idea or PDCA experiment is low-or-no-cost and does not have a hint of negative consequences on safety/quality (our two guard rails, see Power of Ideas pgs. 230-231), we PDCA them! Staff have a very positive experience when they bring up an idea, their colleagues choose to try, it works, and then leaders recognize them.

We found out that most of our staff can huddle daily, they like it, and it's free! In the past, our healthcare staff “huddled” daily, but mainly listened to one-way information from leaders. Converting these to two-way idea huddles allowed BSWH to avoid pulling them away from their jobs to plan and conduct experiments normally done only in projects or committees. And, all staff can be involved.

“People often resent change when they have no involvement in how it should be implemented. So, contrary to popular belief, people do not resist change, they resist being controlled.”

– Ken Blanchard

The second make me needed is a vehicle or a way for staff involvement or engagement in improvements. In a projects-only approach, leaders hire the best and then do not involve them all. Why? The percentage of staff who bring forward ideas can be increased somewhat with a top-down, suggestion system. But, in a few auto companies, I have seen suggestion boxes directly over trash cans. No one knows where their ideas go. These system do not sustain well either.

Idea: Our suggestion is to get 100% of your staff engaged in improvement. Why not? At BSWH, we ask them how we can improve – every day and on every important measure. We try out about 70,000 ideas each year and engage nearly all staff in our Idea Huddles. Staff go home bragging about their improvements.

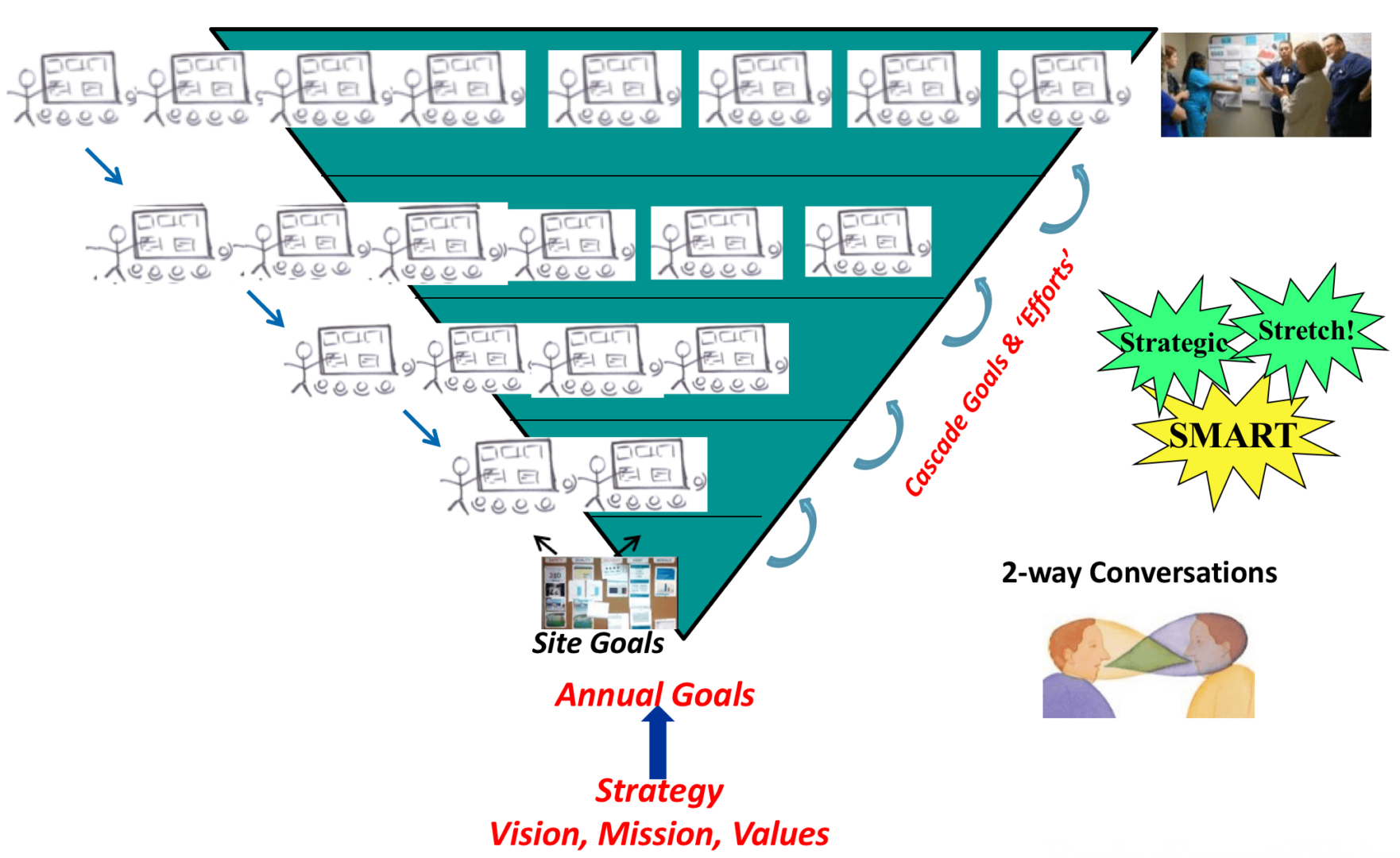

The third make me needed is a vehicle or a way for your staff to communicate effectively. In healthcare, this is a huge challenge; not just because of multiple shifts and locations either. We need a forcing mechanism for better two-way communication. We draw a good organization like an upside-down pyramid, as illustrated below, where the leaders are at the bottom. That way, customers are at the top, as well as our direct performers who serve our customers.

There needs to be rapid communication – up and down. Leaders need to see all the problems. But, staff are closer to the problems and need to help solve them. In most organizations, a leader sees only about 4 to 5% of all problems. They get filtered by the staff. The leaders don't know the problems, thus they can't prioritize the bigger problems that need cross-functional teams or help from top leaders. Also, staff feedback, alignment to goals and priorities do not flow.

Idea: Our suggestion is to do formal Hoshin Kanri at the start of each year and throughout to translate your vision, mission, values and strategy to align all staff. Using two-way conversations (catch-ball), we cascade goals and actions until we can measure something that not only the staff can impact, but is also important to them.

Staff are not motivated by measuring profit or margin. It is not in their control. They are going to measure things like the number of patients they treated, or count specific problems that occurred during the day. These are basically the things they can see and count at the end of every shift. These aligned goals become our huddle board goals.

With aligned staff, actions and goals, you can turn even a big battleship around. The upside-down pyramid shows goals and strategies cascading up, with feedback, results and elevated issues coming down. Our idea cards document not only improvement experiments, but also cross-departmental issues, which can be elevated to leaders. What is your way for leaders to communicate two ways, align all staff, see key problems and receive staff feedback and results?

The fourth make me needed is vehicle or a way for your staff to self-sufficiently solve their problems. What if you do start identifying problems? Then what? Rather than ignoring or maybe overreacting to anecdotal data (“somebody waited a long time last night in the ER…”), what if all managers were invested in the idea of becoming expert problem solvers?

We found after a year or so of doing great idea huddles and implementing hundreds of ideas, they've picked all the low-hanging-fruit. What's left are major, sticky problems without an obvious root cause. Rather than elevating these all to management, what if we taught frontline leaders to solve them?

Somehow, the people seeing and doing the work every day need to actively numerate problems. Staff and their supervisors need to become excellent problem solvers. This is one of the greatest compliments you can give someone. At BSWH, we have adopted the A3 problem solving format – called “local A3s” in the second layer above idea huddles in the pyramid.

On our pyramid, all huddles are led locally by their supervisors (even the C-levels). Notice that nearly all Minor Projects and local A3s are also supervisor-led. We do not have enough black belts or lean coaches in the world to do these daily. And, we would delay their idea implementation if we did make them wait for a facilitator!

Work Hard Building a System for Daily Lean Improvements by All

Once you have aligned staff doing Idea Huddles effectively, watch what they can do! Once the low-hanging-fruit and easy ideas are getting picked daily in huddles, every major project can now focus on transformation. And, each big action can be brought back to the Idea Huddle team! With great respect, project representatives or strategic leaders can say in the huddle, “Here's the next three things we'd like to try on this major effort. Which one you would like to try next?” The same thing is true with problem solving. All problem-solving ideas are tried out – guess where? Correct: in the idea huddles.

After implementing many of their own successful and fulfilling small ideas, huddle teams get hungry for more strategic ideas to try out. This is one way of detecting your maturity in building a wide and deep culture of continuous improvement.

The idea huddle is not only a forcing mechanism for improvement, it is a forcing mechanism for involvement to get all staff involved. It is a forcing mechanism for two-way communication. It is also a forcing mechanism for deploying every one of the key changes from major transformation efforts, projects, and even problem-solving teams. Everything, respectfully, is “docked” back into the huddle! All PDCA experiments are communicated, tried out and checked here.

At BSWH, we don't know if the improvement system shown in the pyramid is the only vehicle or way for staff to make improvements, but if we find better ways, we will adopt them as well.

Every organization needs a forcing mechanism for improvements to overcome inertia and entropy. Ours was to build a daily foundation for small changes by all staff, and where transformational project and problem teams try out their big changes. Our leaders have stretch goals to support and reinforce these systems at Baylor Scott & White Health. What's yours?

“Your transformation as a leader must come before you can transform your business. To lead a change, you as the leader must have already changed.”

– Wayne Smith

Thanks, Steve, for the article!

You can, download this article as a PDF.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Good to see an article from Steve, my old boss from my consulting days. Steve’s experience and knowledge make him one of the go-to guys in Lean healthcare.

Good article. The way I get “make me” across is “I guess they mean it.” If a supervisor tells her employee to put in earplugs EVERY TIME she sees that employee without them, eventually that employee will figure, “I guess she means it.” Employees (and supervisors and managers and C-suite execs) will take care of (eventually if not right away) whatever their boss sees as important. If the boss says something once in awhile (“Put those earplugs in.”), it’s seen as not so important. If the boss says the same thing regularly, frequently, and consistently, it’ll be seen as important and it’ll get taken care of.

What if it doesn’t get taken care of in spite of all your efforts? Well, you need to look at your hiring practices and figure out how you’re managing to hire folks who consistently ignore what their bosses consistently say is important.

Great article. Really enjoyed it. Imagine the possibilities in an environment like this where everyone shows up not just to “work” but to improve everything about the work they do – not only would amazing things get done, but people would have the opportunity to BE amazing every day. I can’t imagine many issues with “engagement” in an environment like this. That is powerful!