I had a great conversation with my fellow Lean healthcare blogger, Brian Buck, the other day. We talk about once a month or so… Brian claims I am mentoring him, but it's a great two-way exchange and discussion that I always learn from.

Brian asked a really interesting question:

“How many ‘just do its' are there really in an organization?”

It's common to refer to small, simple, Kaizen improvements as “just do its” because they don't require the detailed planning and time commitment that you'd see in a “Rapid Improvement Event” (or whatever term you use for a weeklong event).

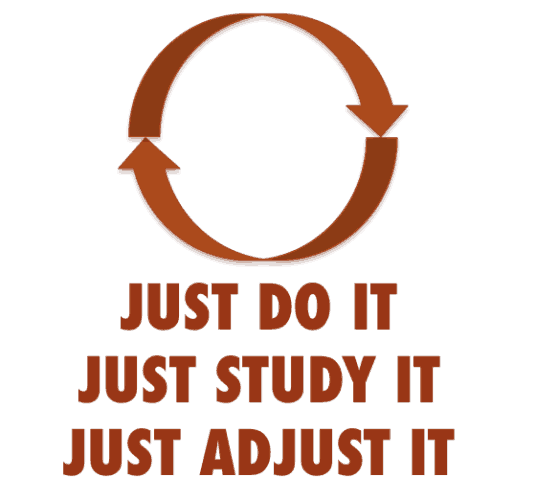

“Just do it” shouldn't imply that there's zero “Plan.”

There's always some Plan involved in a Kaizen, as part of a full Plan-Do-Study-Adjust (PDSA) cycle, no matter how simple the change is.

Let's pick a super simple change… let's move that cup on a hospital lab bench that holds where the disposable pipettes are held. There's at least a slight bit of Plan — identifying a problem (such as the cup being a long reach) and thinking about what COULD be done about it.

I've always advocated for minimizing the amount of Plan when we have a simple change that can be tested… where the Do can be easily followed by an UNDO. If it's a simple, low-cost, low-risk change that can be easily undone, then we'd err on the size of “Just Do It.”

For more complicated changes (such as changing a clinical protocol) or for changes that are less easily undone (knocking down a wall in a nurse's station), we need more Plan. Not too much Plan, not too little. Just the right amount for each change.

Even with a small amount of Plan and a quick and easy DO, we cannot forget Study and Adjust.

To repeat, do NOT blow through Study and Adjust.

So, my modification to the famous Nike logo and slogan would be this:

Even for a simple change… we still study the effects. Moving that small cup that holds the pipettes… what do employees and the team think about that? Did it improve ergonomics? Did it make work easier? Did that create any problems that we didn't anticipate?

We don't necessarily need to collect lots of data for a small change. Sometimes, we just know that the small change was really an improvement… unless we later discover otherwise.

After we Study, we can then Adjust, if needed. Our next step might be to Adopt the change (as is), Adapt it (tweak it in some way based on what we've learned), or Abandon it (and go back to try something different).

Even if we “Just Do It,” the Kaizen cycle does NOT end with Do.

Here's a video that I made a few years ago for KaiNexus on this topic… how do we know if a change is really an improvement — Oops that video isn't available anymore.

How do you treat “Just Do Its” in your organization? How do you find the right balance? Leave a comment on the post, I'd love to hear from you!

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

Totally agree.. We tend to forget about the whole cycle of change because we “assume” the change is simple and will result in improvement. One of the things many people skip is proper planning for significant improvements, let alone for a just-do-it change. You could add “Just plan it” to the slogan !

In my opinon,we ALWAYS need to plan as necessary, do as planned, study as necessary, and act as necessary, and it’s all situational.

The video about how do we know if a change is really an improvement, is not available anymore. Could you please share a useful link on this topic? Thank you!

Hi Diana – I’m sorry that the video isn’t available anymore.

I guess my thoughts, in summary, would be this:

1) Can we measure something to see if the change is really an improvement? Does it benefit safety, quality, flow, cost in a meaningful way?

2) If we can’t measure it precisely, is there consensus amongst the employees that the change makes their work easier or makes things better for the customer in some way?

I have read it, useful information