I was preparing for the Gemba Academy webinar that I'm doing next Tuesday (you can still sign up) on:

Stories about the Eight Types of Waste in Healthcare.

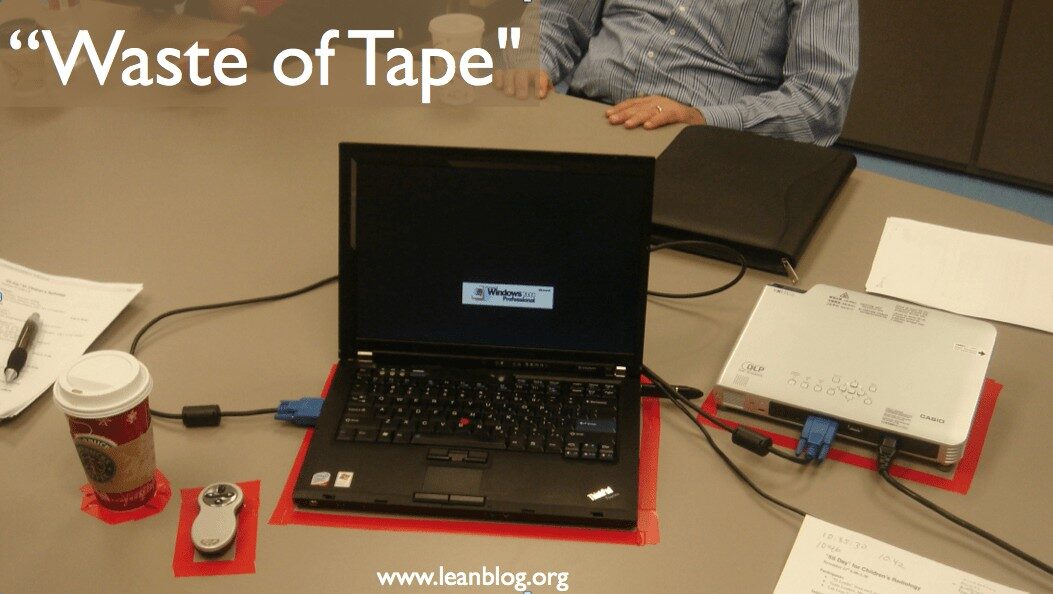

I found this fun picture from about 2008 that I decided to incorporate into my talk. I was leading some 5S work in an X-ray area, where the focus was on preventing delays to patient flow by making sure staff had the right supplies available in the right locations.

The team played a prank on me while I was away from our conference room. :-)

I dubbed this the 9th type of waste… wasting tape to do unnecessary “5S” type work. Putting tape around my laptop wouldn't be Lean, it would be L.A.M.E.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

For a second, I thought that was a photo from your home office. Do you still have kanban for your paper towel supply? :)

:-)

Yes, the kanban bin sizes are a bit smaller, since we’re in a condo, not a house, and I don’t have room for those Costco mega packs.

So, I go to the store more often!

OK, Mark, maybe in this instance LAME, but way back in the day, I did something similar in my office to guide the nightly cleaning crew. I was tired of my workplace being a mess when I would arrive in the morning. It actually worked…so while I think tape is funny as a waste, I have to say it can be useful depending on the context. :-)

It’s not L.A.M.E. if it’s helpful to you… and it sounds like the tape was your choice and to your benefit… so great! :-)

I completely agree, but it depends where one is in the journey.

I once taught a group the fundamentals of Lean. For folks in that group, first learning about Lean and the application of 5S might inspire them to give it a shot. And, if the application is something silly such as applying the “every thing has a home and every home has a place” for someone’s desk, then at least they’re applying the principle.

Silly application, but we need to celebrate the effort.

I see your point and I try not to be too hard on people who apply a tool in a way that doesn’t really solve a problem.

If a person taped off their own desk… well OK, cool, they are trying. I would celebrate the effort and realize they will move on to more meaningful improvements. Being discouraging doesn’t help anybody.

Now, if a manager or a “lean improvement specialist” FORCED people to tape off their desks, I might challenge them a little more and ask “what was the problem being solved? did this solve a problem?”

So I see a difference between initiating something and forcing others to do something. It’s more “L.A.M.E.” when it’s forced in a topdown way.

A classic example of people deploying a tool to fix a problem that probably doesn’t exist without understanding the principle the tool was designed to achieve.

Sadly the classic western approach to Lean deployment destined to fail.

It *would* be an example of that, but it was a joke… a prank. I think I taught the team well that you don’t improve things by merely putting tape around everything.