What I learned in Japan confirms it: the power of Lean isn't in the templates–it's in the thinking, the actions, and the learning behind them.

A key takeaway from Katie Anderson's Japan Study Trip resonated deeply with me: thinking and action are far more important than templates. This insight, shared by Isao Yoshino, a retired Toyota executive, and other leaders we met at various companies, has significant implications for how we approach improvement practices.

Read my blog posts from all of my Japan tours

This theme is particularly relevant to methodologies like A3 problem-solving and hoshin kanri (strategy deployment). It's all too easy to get caught up in the details of the template–whether it's the layout, the boxes, or the software–while losing sight of the true purpose.

As we heard repeatedly during the trip:

“The template isn't the most important thing.”

Two Examples, One Truth

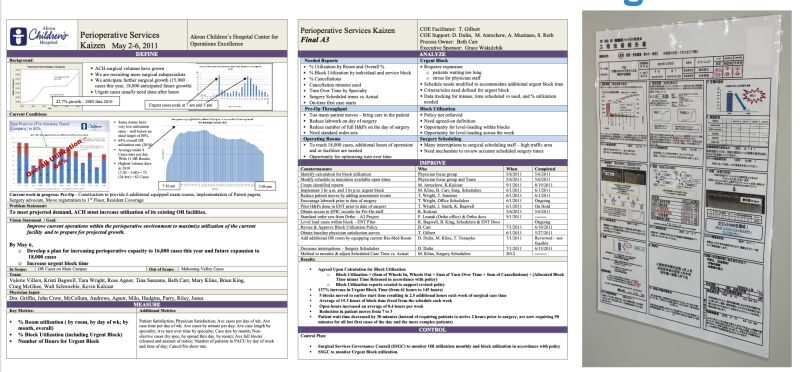

Here are two contrasting examples of templates:

- A DMAIC-based A3 from an American hospital (on the left)

- A “10-box” style template from a Japanese manufacturing company (right)

Does the size of the paper matter? Whether it's hand-drawn or digital? Portrait or landscape? These are secondary concerns. What really matters is whether the template serves as a tool for scientific thinking, structured problem-solving, and iterative improvement.

The Japanese template has these boxes, by the way, in the “Process improvement report,” starting with the “theme”:

- Reason

- Current State

- Goal

- Plan

- Factor (“cause”)

- Investigation

- Measures

- Effect

- Standardization

- Reflection and Future

Mindset Over Mechanics

I'd much rather see a messy, hand-drawn A3 on a whiteboard (or paper) that reflects real PDSA (Plan-Do-Study-Adjust) cycles than a perfectly formatted document that's merely a formality. A3 problem-solving is meant to be dynamic, iterative, and reflective of active learning.

When Lean tools are reduced to “tick box” exercises, we risk losing the essence of Lean itself. The real impact comes from the mindset, behaviors, and processes that drive these tools–not the tools in isolation.

What's Your Experience?

How do you emphasize thinking and action over the format of templates in your improvement work? Let's focus on what truly matters: fostering the scientific thinking and iterative action that lead to meaningful results.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

The quality of the thought and problem-solving that goes into employing lean technologies determines how effective they are. As an alternative to actual iterative learning, businesses wind up concentrating on perfecting the format. The distinction between the 10-box Japanese template and the DMAIC-based A3 demonstrates that mentality matters more than structure. Active, hands-on problem-solving is more my style than mentally jotting down every solution. Instead of merely checking a box, A3 thinking needs to spur actual practice development. However, it is safeguarded at the core of Lean towards genuine change that endures by concentrating on the behaviors and procedures that underlie the tools.

Comments are closed.