I am saddened to hear of the death of Ritsuo Shingo (1947-2023), as announced by the Shingo Institute. He was the son of Shigeo Shingo, for whom the Shingo Prize and Shingo Institute were named. I want to express my deepest condolences to his family, friends, and everybody who knew and worked with him.

In his own right, Ritsuo had an incredibly successful 40-year career at Toyota, and he was affiliated with the Shingo Institute in recent years.

Ritsuo was the founder and the first president of Toyota China. Under his leadership, Toyota China became one of the most successful ventures of Toyota worldwide. Following this success, he was appointed as the president of Hino Motors and then served as the president of GAC-Hino until 2009.

Shingo was the translator of the first book on the Toyota Production System in English written by his father, TPS pioneer, Shigeo Shingo in 1976. He applied his father's and other TPS pioneers' teachings into his management practices.

In this post, I will share some reflections and a re-issue of the Lean Blog Interviews podcast episode from 2021 when I was honored to have Mr. Shingo as my guest.

You can share memories and photos with the Shingo Institute here.

But first, a video from some of the people who knew him best:

Shingo Institute Video:

Meeting Ritsuo Shingo

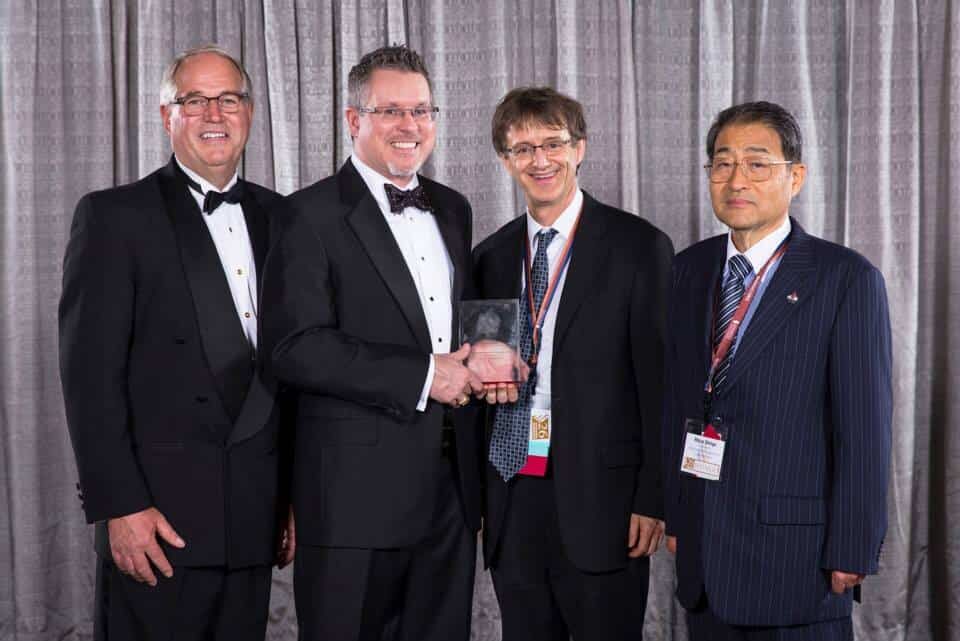

I first met him in 2009 when my first book Lean Hospitals was a recipient of the Shingo Research and Professional Publication Award. Here is a photo from the event with Bob Miller (then the director of the Institute).

As part of the event, our mutual friend Norman Bodek (who passed in 2020), arranged for me to have some time together with him and Mr. Shingo.

One topic of conversation with Ritsuo was mistake-proofing in the context of Lean and the Toyota Production System. Shigeo Shingo is closely associated with the development of “poka-yoke” (or error-proofing) techniques at Toyota. For example, see the book published by Norman in 1986: Zero Quality Control: Source Inspection and the Poka-Yoke System.

I remember showing Ritsuo some photos and slides with examples of mistake-proofing in healthcare (and, in some cases, the lack thereof). I remember him being surprised and bemused by some of the preventable mistakes that occur in healthcare due to a lack of mistake-proofing. I am still looking for my notes from the discussion.

Joe Swartz also got some time (and a photo) with him in 2014 at the award ceremony for our book Healthcare Kaizen:

My 2021 Podcast with Ritsuo Shingo

You can check out the episode from 2021 — it was Episode #409, and I'm re-releasing it this week as a Bonus Episode.

I also recently had a full transcript made, which can be found on the episode page, along with the audio, which is also posted below:

Some Highlights from the Transcript…

Here are a few excerpts from the 2021 episode on the technical side of TPS and the people side. I didn't release the episode in video format, but I will put together some clips, including the first one that's shared below.

How Do You Explain TPS?

“…my understanding is it's accumulation of small improvements, so lot of improvements.”

Toyota made a lot of improvements. Still, that improvement is going on. The plant, when I joined Toyota Motor in 1970, is not the plant right now. It's a big difference. Why? Because Toyota has been changing, are flexible, changing, continuous improvement. Many factors are there to be successful for Toyota.”

On Misunderstandings About “Just in Time”

“Just-in-time is the only necessary products, necessary volume, necessary timing. That means if you don't need to supply to Toyota, you don't. Toyota requests only products, and volume, and the timing, then both Toyota and supplier can reduce inventory. Supplier don't carry any inventory.

There was a big misunderstanding in the Western world that Toyota was enjoying just-in-time, but not the suppliers. They should keep big, big, huge inventory to enable just-in-time, but they don't.

Why? Because as soon as they produce, they can ship to Toyota. That is frequent delivery. They don't need to keep inventory. Whenever Toyota requests to produce, that means Toyota are sure to receive so that the suppliers don't need to keep any huge, excessive inventory.”

“There is no workers problem”

“I came to conclusion that there is no workers problem. Wherever you go. In China, we made it. Workforce did a good job. Wherever you are. You are in Mexico. You are US. Even if you are China, Vietnam, wherever you go, there's no workforce, no workers problem.

All this, if there is a problem, it is the management problem. If management people said, “Blame the people,” plant manager…quite often I heard the plant manager blame people. “Oh, they are not good. They don't listen. Even they have learned, they forget. Very poor, very spoiled. No good workers.”

I told that plant manager, “Oh, you sounds like you are escaping from your responsibility.”

It is your responsibility to educate, train the people, and communicate with them, and pull out their talent, develop their ability so that they can make contribution to any activity. It is not simple, but it is like an orchestra harmony. Everybody should play their role and try to be better for the benefit of their company.”

Read more from the transcript… so many insights from Ritsuo Shingo.

Thank You — Rest in Peace

Mr. Shingo, thanks for everything that you shared with us, privately and in more public ways.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: