While in Japan recently, I shared a short post on LinkedIn that I want to expand on here.

Over the years, I've learned that not every Japanese company practices TPS, Lean, Kaizen, or TQM. These approaches aren't the default–and they aren't inherently easier just because a company is in Japan, despite what some might assume.

During one visit, a leader told me plainly:

“We were not always a Kaizen company.”

That might surprise some readers. Kaizen wasn't ingrained in their culture from the start–it's the result of a deliberate shift over the past few years. The catalyst? A new CEO, formerly with Toyota, who made employee engagement in continuous improvement a clear priority.

Leadership matters. In fact, leadership is often the turning point between a stagnant culture and one that embraces learning and improvement.

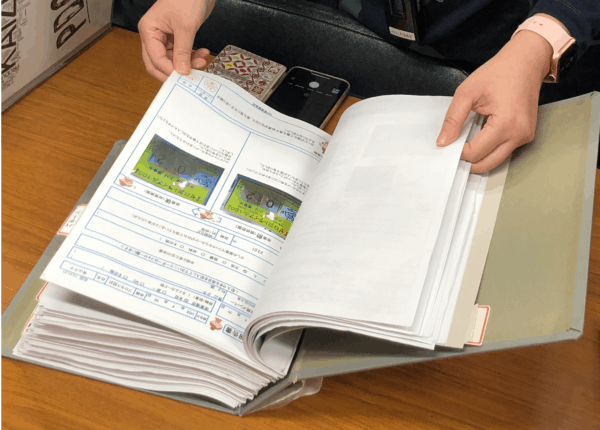

The photo below is from another manufacturer that has practiced Kaizen for over four years. Each binder you see is packed with single-page summaries of small but meaningful improvements–tangible proof of what's possible when a culture takes root.

Paraphrasing Mitt Romney, we have binders full of Kaizens!

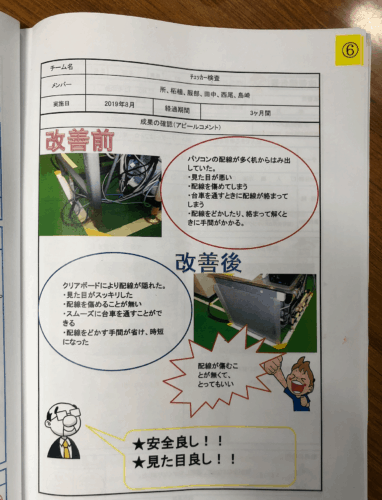

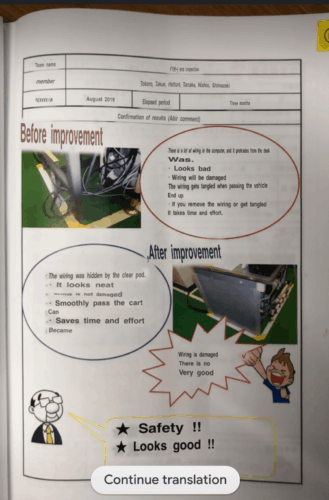

Here is what one of those Kaizens looks like, along with an automated translation was done via the Google Translate on my iPhone:

What we see here is a similar format to what I've used in different organizations, something that I've called a “Kaizen Report” or a “Kaizen Summary,” as we've documented in Healthcare Kaizen (and you can find templates like this on our book's website).

Updated: Here is a ChatGPT 5.0 translation and explanation:

Translation

Team name: Checker Inspection

Members: Tokoro, Kakiue, Hattori, Tanaka, Nishio, Shimazaki

Implementation date: August 2019

Duration: 3 months

Before improvement:

- Many computer cables were sticking out from under the desk.

- Poor appearance.

- Risk of pulling or damaging cables.

- Cables could get caught when moving carts.

- Untangling cables took extra time and effort.

After improvement:

- Installed a clear board to hide the cables.

- Appearance is much tidier.

- No risk of pulling cables.

- Carts can pass through smoothly.

- Saved time and effort by reducing cable tangles.

Speech bubble: “No more damage to cables–this is great!”

Cartoon character: “Safer!! Looks better!!”

This was a simple but powerful example of Kaizen–a small improvement that makes a meaningful difference.

In this case, the problem was a tangle of exposed computer cables under a desk. Not only did it look messy, but it created risks: cables could be pulled out accidentally, carts could snag them, and untangling them wasted time.

The team's countermeasure was straightforward: install a clear protective board to shield and organize the cables. This quick fix improved safety, eliminated snags, reduced maintenance time, and created a cleaner, more professional appearance.

It's a reminder that Kaizen isn't always about complex systems or big investments. Sometimes, it's about seeing a small irritation, recognizing the risks it carries, and making a low-cost change that improves both function and form. Multiply that mindset across an organization, and those small wins add up to big cultural change.

Tour participants loved flipping through the binders… even without understanding Japanese, the photos help you get a sense of the types of small improvements that are being made so frequently. I don't have an exact count of how many Kaizens have been documented.

Here is another blog post, from my first visit in 2012, on the theme of “this isn't easier in Japan”:

Lean, TPS, Kaizen, TQM–these aren't automatic in Japan or anywhere else. They don't appear by magic, and they don't sustain themselves without intention. They take leadership that models the behaviors, allocates the time, and reinforces the mindset every single day.

In the end, it's not geography or tradition that makes Kaizen thrive–it's leaders who choose to make continuous improvement part of the culture, and who keep choosing it, day after day.

See more posts about Japan trips and my lessons learned.

Join me in Japan to discover how hospitals and manufacturers build cultures of safety, learning, and continuous improvement. October 2025 and beyond…

Here is the original LinkedIn post with a lot of great comments and discussion:

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Interesting article, Mark! If the companies you visited don’t admit that they’re not TPS, Lean, Kaizen or TQM, then what do they call themselves in the context of business or operational excellence?

Ray –

I’m not sure if I understand your question. All of the companies I visited say they are using TPS, Lean, TQM, Kaizen and or all of the above.

But the one I’m referencing here would probably say they had no form of operational excellence approach before they started with Kaizen.

Mark