I take no joy in the troubles of any automaker, be it Tesla, Nissan, Toyota, GM or any others over time.

Of course, Nissan and GM have been in the news most recently, with the firing (and jailing) of Nissan and Renault CEO Carlos Ghosn. And now, GM has announced major layoffs, the cancelation of some passenger car programs, and the shutdown (and possible closure) of five plants in North America.

I was talking to a friend the other day and I predicted that we'd see news headlines about something like “GM to get Leaner.” These headlines would be using the word “lean” to mean “get smaller” instead of referring to “Lean” (which I capitalize as a proper noun) as a synonym for the Toyota Production System.

I was disappointed to hear GM's CEO, Mary Barra, a long-time GM employee using the word “lean” in the context of the company getting smaller. It's a shame that the word “lean” and layoffs in headlines will only reinforce the perception of “L.E.A.N.” — Less People Are Needed — as detractors often say.

As she was quoted in many articles:

The cuts will make GM “lean and agile” as the company aims to “lead in autonomous and lead in electric vehicles,” Barra said.

She obviously knows the term “Lean” as in “Lean manufacturing.” Lean is something GM has been chasing for over 25 years. I'd guess that parts of GM use Agile software methodologies.

Ba'srra clearly speaking the language of Wall Street… lower-case lean (meaning smaller) and lower-case agile (meaning faster and more nimble) instead of the language of the formal Lean and Agile software development methodologies.

Why couldn't she have said. “We are going to be smaller and more focused, which will allow us to move faster and make the right investments for the future?” She could have avoided the words lean and agile.

When I worked at GM from 1995 to 1997 (at a now-closed engine plant in Livonia, Michigan), “Lean” was a relatively new term (The Machine That Changed the World, the book that popularized the term, was first published in 1990). Although it was clear that GM was copying Toyota and playing catch-up to them, we weren't really allowed to use the words Lean or Toyota anything. GM used a term “Competitive Manufacturing” and, later, “Global Manufacturing System” as terms for Lean.

Lean, based on the Toyota Production System, isn't about shrinking and cutting. Some have said that Lean is a better growth strategy (being able to do more work with the same number of people) instead of being a way of coping with a shrinking company.

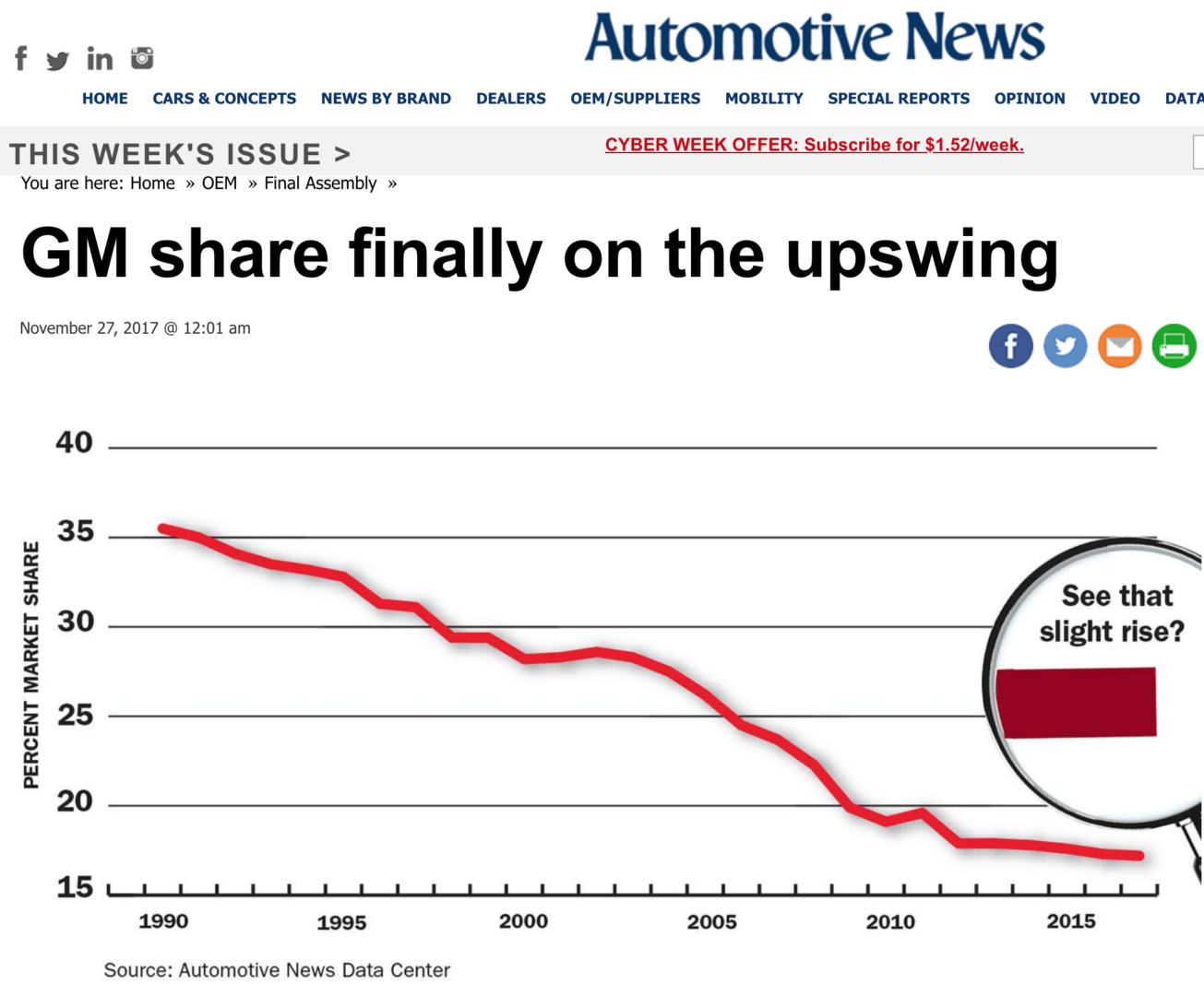

You don't need to draw a “Process Behavior Chart” to see that there was a meaningful downward trend in GM's North American market share, although I think the Automotive News headline about “an upswing” in market share is meant to be ironic or some dark humor?

As I write about in my book Measures of Success, run charts like this provide important context. As I also write about in the book, two data points do not make a trend. Just reporting a “slight rise” would be misleading without the context of how market share has pretty steadily declined over time — it's clearly not just fluctuating around an average (although maybe it was just fluctuating from 2012 to the end of that chart.

“Since 1990, GM's share has dipped in every year but three — 2001 and 2002, a period in which the company's wildly effective “Keep America Rolling” campaign after 9/11 boosted share, and 2011, when its share increased 0.5 percent as it felt the effects of its emergence from bankruptcy.

But GM has fallen in every year since 2011 — until this year.”

When I was at GM, I remember Rick Wagoner (who was a senior executive, but not CEO yet) was in some embarrassing rap-style video (he was wearing sunglasses, so he was “cool”) where they were talking about how market share wouldn't (or couldn't?) fall below 30%.

Except it did… and it kept falling…

There are many reasons for that, of course. There's more competition in the market. Even though GM has been building much better (even award-winning) cars, the market has a long memory about the really bad “Big Three” products of the 70s and 80s. It's hard for a company to regain trust with the car-buying public.

The reasons given for the recent layoffs include a shift in consumer tastes from cars to crossovers, SUVs, and trucks.

It will be interesting to see how companies like Toyota, Honda, Nissan, BMW, and others that build cars in the U.S. respond to these trends. They face the same steel tariffs and other economic factors. Will we see a difference in how they respond?

My friend Steve Leuschel also raised this issue about the phrase “lean and agile” on LinkedIn yesterday and he posted a video:

What's the best way for GM to address all of this with any form of “mutual trust and respect?” Will they operate that way?

Edit: Adding some additional thoughts. When people in healthcare fear that Lean means layoffs, I can't blame them given the reality that many health systems have been in a cost-cutting layoff-driven mode for a while without Lean.

Lean can actually be a great alternative to layoffs. When we focus on improving the work, we can improve safety, quality, delivery (access), and morale… which leads to lower costs.

https://www.leanblog.org/2014/06/the-goals-that-matter-sqdcm/

I realize the word “Lean” has bad connotations in everyday usage. I had a nurse tell me once, “Oh we're already lean… we're understaffed as it is.” She was thinking of “lean” (not having enough) when “Lean” is about making sure you're not understaffed. Some of it is the problem with the word and some of this is about management's old cost-cutting habits…

Lean 101: Understanding the Basics of Lean Thinking and Methodology — What is Lean?

Here's the origins of the term “Lean production”:

The Evolution of ‘Lean Production': Reflecting on 25 Years Since the Term Was Coined

What if they had called it “Effective Production” or “Happy Production?”

Now, in the case of GM, Lean manufacturing methods applied to the wrong products won't do much good. Lean manufacturing and “making the wrong products righter” isn't going to help a company that much. That's why strategy, customer focus, and long-term thinking are an important part of a truly “Lean enterprise.”

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

The discussion on Linkedin:

Mark – Thanks for writing this blog. I was cringing all morning listening to the GM news on the radio and hearing the word “lean” being used repeatedly. A few weeks ago I visited a GM plant for a gemba walk and heard all about GMS. The host and tour guide showed a picture of Lean Hospitals and recommended we read it.

The tour guide from GM recommended my book? That’s cool… thanks for sharing.

Yep. I think he was trying to convince us that Lean works in hospitals. I was already convinced.

The Toyota view:

“Toyota US chief says car sales are close to bottoming out”