While this photo looks like a dangerous situation, I guess we can call it a light-hearted look at a questionable improvement, via the wonderful FailBlog.org and its ThereIFixedIt.com site (photo link).

see more epicfails

What would happen in an environment where people were using a Visual Idea Board, as described in the upcoming book Healthcare Kaizen?

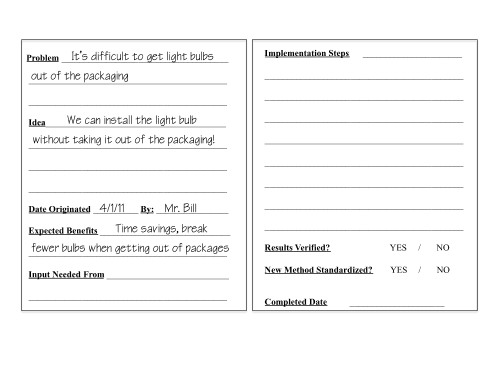

An employee might fill out an Idea Card, as I've mocked up below:

Let's say an employee brought this card to you. You would talk about the card and thank the employee for identifying a problem statement. Maybe we're buying bulbs in retail packaging that's hard to open and there has to be a way to address that. Now, the idea of installing the bulb while still in the packaging… this is why Kaizen involves at least a quick discussion with a supervisor. It's not meant to be a bureaucratic process, but sometimes Kaizen requires the input and experience of a supervisor.

The supervisor (or a teammate) might question if leaving the packaging on might create a fire risk. You might decide NOT to try that idea (safety risk outweighs time savings), but you're not done.

In a traditional suggestion box approach, the focus is on the idea. So we'd say “no” to the idea – it's not safe, it would be deemed a “bad idea.”

But with Kaizen, we honor the identification of a PROBLEM – the packaging is hard to open. The role of the supervisor is to work with the employee to find something that can be done. Maybe we need to buy bulbs that come in a type of packaging that's easier to open? The supervisor certainly shouldn't say “Hey, dummy, are you trying to burn the place down?”

Kaizen is about collaboration and coaching toward solutions, not accepting or rejecting ideas like a judge.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Although tongue-in-cheek, this is a great example of good leadership behaviors. A quick review review of the kaizen card, allows the supervisor the opportunity to become a teacher and use that opportunity to teach the employee about safety and about the kaizen way of solving problems.

Cheers

Yes, one of the greatest insights I’ve gotten in my Kaizen education is the idea that a “bad idea” is really an opportunity to coach, mentor, develop, education… not reject, ridicule, or punish.

Comments are closed.