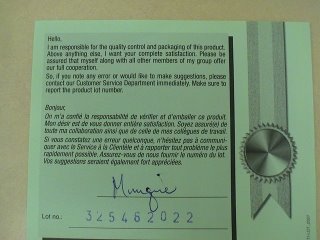

I saw this card (click on it for a larger view) included with some medical products that were shipped to a hospital. It's signed by a production worker (I assume) and says “I am responsible for the quality control of this product…”

I saw this card (click on it for a larger view) included with some medical products that were shipped to a hospital. It's signed by a production worker (I assume) and says “I am responsible for the quality control of this product…”

The card really should have been signed by the CEO with the CEO's name. As Deming said, top management must be responsible for quality and the systems that ensure. It would be unfair to hold a production worker personally accountable if that worker was forced into using cheap supplies from the lowest- cost supplier or the the worker wasn't allowed to select the right production tools to help ensure quality. To me, other than providing the lot number, this card itself is “waste” or “muda.”

Technorati Tags: Lean Manufacturing, Quality

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

Mark,

I think it’s very important to distinguish accountability and responsibility. The worker stated he/she was responsible. That doesn’t mean accountable. Responsible means having some control over the outcome or having an obligation. Accountable is the person who must justify or answer for the results. The CEO may be accountable for quality, but if they are the only one responsible, you’re headed for a big problem. If signing a little card acts as a reminder to the employees of their responsibility, then I applaud them for this small gesture.

If “everyone” is responsible for something, usually “no one” does it. I like this idea. I understand what Deming was getting at, but just because Deming said it, doesn’t make it so. I have seen very few manufacturing companies where the employees were prisoners of the system management imposed on them. Most of the time if the employees don’t like the system they will complain about it, change it, or leave. Jamie got it right in his comment–there is a difference between accountability and responsibility.

Thanks for the comments. I guess I’ve just been in too many environments where there are signs saying “quality is YOUR responsiblity” when every management decision made went against quality. And that wasn’t just GM….

You guys have it wrong… management IS responsible. If your some 25 year employee and management starts sourcing stuff from some shit supplier, you’re just going to up and leave? Get real. I bet half the people signing these kwality kards are just doing it and gritting their teeth or not even thinking about it. Don’t let management off the hook that easy.

Is this good or not? It depends…

If the organisation providing the product/service is dysfunctional and the top management decided that the issue is the workforce and lack of responsibility; then the signed paper is a bad outcome of an irresponsible command & control environment.

If this is the icing on the cake of a good organisation/product/service then there is nothing wrong at all in my opinion.

Osvaldo

There’s a chance that the person that signed it can’t even read.

I’ll have to post some time copies of the 1995 era memos I have from GM about how the workers weren’t taking enough responsibility for quality. This came after management wouldn’t let UAW workers do their hourly quality checks because it slowed down the machining line. Management knew exactly what they were doing (getting short term production numbers at expense of quality) and when it bit them in the butt (hundreds of bad engines reaching the Hamtramack plant), they blamed the workers.

It’s because scars like that where I tend to come down hard on management. Not that the UAW was perfect or that every work cared, but many of them were rightfully disgruntled because management wouldn’t let them do quality work.

Dear Mark,

I see these quality cards all the time, but never gave them much thought until your post. You make a great point that this one individual could not possibly “be responsible for the quality control of this product”.

At the least, this note implies that maybe for this company the meaning of quality has been reduced to inspection before shipment. But it may indicate something more – a belief by management that quality is something that can be delegated to an individual or an organization.

Yes, Mark. My point wasn’t that the worker isn’t responsible. My point was, as you put it well, any one person can’t be solely responsible, whether they are a builder (and no one person is ever responsible for building) or an inspector.

I don’t think the sayings about management true are necessarily true BECAUSE Deming said them. I’m saying I think it’s true based on my experience and it happens to match up with Deming’s views, which I respect very much.

Deming was right about the management and 90% stuff. However, I remember my first job after the military. I wired up stamping equipment. They gave me a stamp with which I stamped my name on the serial plaque of the stamping equipment. I followed prodecures, worked in an environment, used tools all controlled by management. Still, putting my name on that equipment changed the game for me. At the time I thought it was a really good idea. Maybe it made me more dilligent. I still think it is a good idea.

Deming is right though.

B Baker — did that stamp do anything to improve quality? I imagine quality is really a function of (at least) two inputs: Quality System Design + Does the worker care?

The quality system is management’s responsibility. You can’t make people care… but management has to avoid hiring people who don’t care and then avoid demotivating them. You can take good people and quickly make them NOT care by treating them badly or not listening to them, etc. That’s also management’s responsibility.

I go back to Jamie’s comment from this morning. A basic tenet of process design is that you can have many people responsible, but only one accountable. You can delegate responsibility, but not accountability. (The other parts of the model are “consult” and “inform”–they reflect four different ways in which people touch a process).

I agree with Jamie that unless you distinguish between accountability and responsibility, all the talk about “responsibility” is not really meaningful. Do you mean accountable, as in the buck stops here, I can’t delegate accountability? Or do you mean responsible, as in I’m the one who actually did it? (It doesn’t matter much whether the one responsible can read or not, (s)he’s still the one responsible.

Both are useful concepts. In this case, I would argue the right person signed it, and the right word was used. If Johnson and Johnson passed on a faulty stent to a hospital, I already know who J&J’s CEO is, it doesn’t do anyone much good to have his signature on a shipment; I want to know the name of the inspector, so I can immediately trace back problems to find out the process source of the error. It’s not about blame, it’s about how to fix things.

And if and when it’s ever time to sue, then that would be the guy accountable–the top dog.

Mark,

I can’t say that it helped quality. I wouldn’t count on it to improve quality. We got a new plant manager and stamping our names under the company’s logo was one of many changes the he implemented early in his tenure. It got my attention. He also took down the time clock–we just wrote down our time and turned it. He put a couple of the engineer’s desks on the shop floor. He broke the departments up and put us in cross functinal teams that stayed with the same piece of gear the whole way through the process. We started wearing uniforms, company provided a laundry service. We got PPE budgets. You bought your own gloves,hearing protection, and safety glasses out of that budget. Stamping my name on serial plaque made an impression on me. Upon reflection, I can’t say it made any impact on quality.