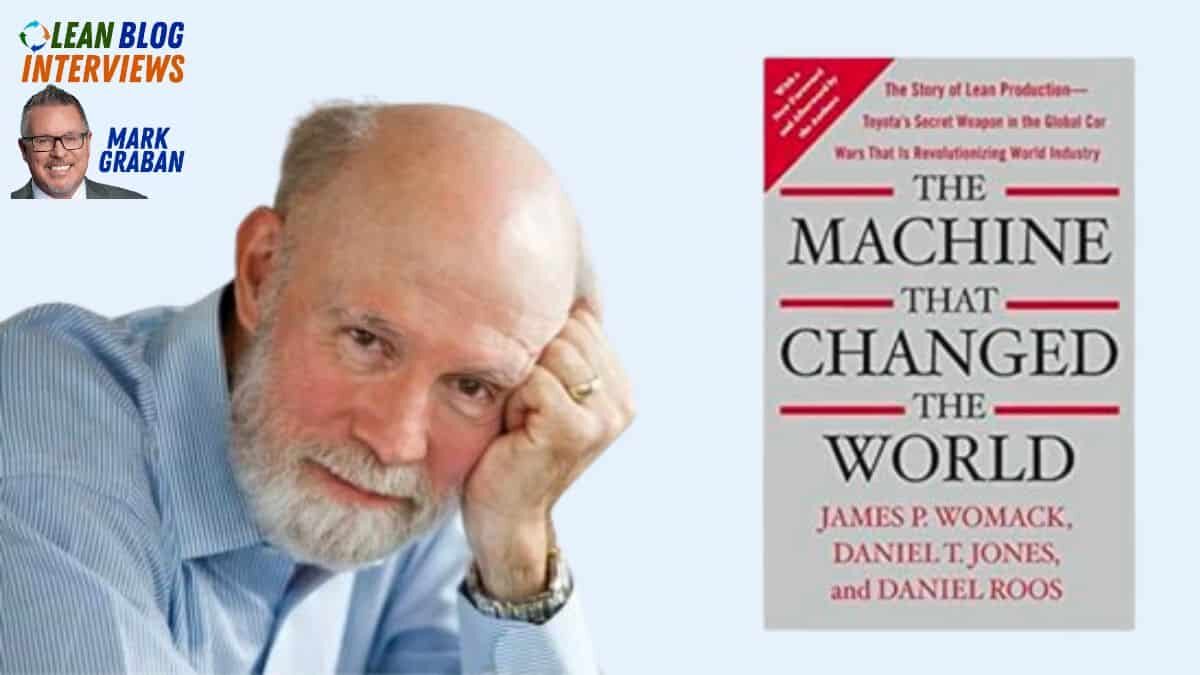

Episode #19 of the Lean Blog Podcast brings the return of Jim Womack. Jim was sitting in Melbourne Australia, where he had been speaking about lean healthcare, a topic that we will discuss in a future podcast.

In this podcast, we talk about Jim's reflections on the book The Machine That Changed the World and its recent reissuing by the publisher (with updates). In the podcast, Jim not only talks about Toyota's success, but ways in which Toyota could fail or falter in the future. This is the first part of our discussion. I will release the second part in the upcoming weeks.

If you enjoy this podcast, I hope you'll check out the rest of the series by visiting the LeanBlog Podcast main page. Earlier podcasts with Jim can be found here (#12) and here (#13).

Show Notes and Approximate Time, Episode #19

- 1:30 Jim's thoughts on “Machine,” written about “why the teams [GM, Ford, Chrysler] can't win the away games”

- 1:55 The book before “Machine” was “The Future of the Automobile” (1984)

- 2:15 The job of “Machine” was to describe a complete business system… “the biggest disappointment… was to have people tell me it was a great book about factories.”

- 3:00 “You get the feeling that a lot of people read the book, but just that one chapter [on manufacturing].”

- 3:50 Probably about a million copies sold so far

- 4:00 The publisher said that 2007 is the year when Toyota is probably going to pass GM, so why don't we re-issue it?

- 4:20 The new subtitle is “Why Toyota Won”

- 4:45 “We've learned a lot since then… some of what we told you in the book is not exactly right, so we're thinking of it not exactly as a product recall, but as a model line enhancement. This is what might have been the 1991 model if we had done annual model changes.”

- 5:30 Is there risk of a backlash with Toyota becoming #1? Jim talks about “ways in which Toyota could lose,” starting with manufacturing

- 10:50 “They could go native”

- 10:05 How Toyota could lose with the product development system (book by Al Ward)

- 10:40 The Jeff Liker book on product development (“they are complements to each other,” Jim says): The Toyota Product Development System: Integrating People, Process And Technology

- 14:30 How Toyota could fail with their dealer system

- 15:45 Jim's essay on farmers and hunters

- 22:40 GM and the X-cars (info here and here)

- 24:10 Jim asks, “Can Toyota screw up? For the short term, the answer is no, for the long term, absolutely!”

- 24:30 “Most any other company would be fat, dumb, and happy.”

- 24:50 What about the excuses the Big 3 make about currency factors, etc.?

- 25:30 How the Big 3 are like the Detroit Lions

If you have feedback on the podcast, or any questions for me or my guests, you can email me at leanpodcast@gmail.com or you can call and leave a voicemail by calling the “Lean Line” at (817) 372-5682 or contact me via Skype ID “mgraban.” Please give your location and your first name. Any comments (email or voicemail) might be used in follow ups to the podcast.

Listen to the podcast here

Jim Womack, “The Machine That Changed The World” Revisited

This is episode number 19. Our guest is Jim Womack of the Lean Enterprise Institute. We'll be talking about the re-publication of his book, The Machine That Changed the World. Jim will be talking about Toyota's success but also some ways that looking ahead that Toyota could falter or fail in the coming years. This will be the first part of what's a two-part discussion with Jim. I hope you'll read the second part.

—

Joining us from Melbourne, Australia is Jim Womack. Thanks for being here on the show, Jim.

I'm delighted to be here.

I wanted to talk about the new edition of The Machine That Changed the World that's coming out. I believe somewhere in the near future. I was wondering if you could talk to us about what the motivation was for putting out a new version and what thoughts you have. It's been many years since the book came out.

A long story, we started working on it at the end of the 1970s at MIT. The question was why the teams can't win the away games. At that time, not so much home games were losing but away games. That was 1979 when MIT started its car projects. We had an intermediate product called Future of the Automobile in 1984. That had the storyline but just didn't have a lot of the evidence that we thought we needed. That's what she was supposed to do, supply the evidence. The machine's real job was to describe a complete business system.

When it came out in the fall of '90, we were hoping that everybody would understand this was interlocked mutually self-supporting businesses and that's probably the biggest disappointment for the public reaction to the book. It's been many years and I had it happen to me here in Australia. Most people over the years tell me it's a great book about factories. If you read the book, we devote the same number of words in five different chapters to product development, purchasing supplier management, customer relations, and the general management of the business and operations.

We make it very clear on every page that the stuff is all interlocked. In some ways, a lot of people read the book but I always get to feel that nobody read that chapter. That came out in the fall of 1990. I wasn't sure anything was going to happen when it came out because at that point, that particular year, the US car industry, and that was a key example, was doing okay.

The recession in 1991 came along and at no time fell off at the end of the earth again. We nearly went bankrupt in 1992. Suddenly, we were off to the races and we've had continuous sales over many years. At one time, there were two competing Chinese translations, both of them pirated. Therefore, it's a little hard to know how many translations might be out there. Anyway, enormous volume. Probably 1 million copies sold so far. We hadn't had any particular plan of what to do with it but then the publisher, Simon & Schuster Free Press, said, “This is the year 2007 that Toyota apparently is going to pass GM. Why don't we reissue this?”

With Dan Roos at MIT but Dan Jones and I have been the people who kept up with it until Dan Roos has gone on to other things. He will tell you we need to put a new product on it which has the title, “Why Toyota Won,” but puts this book of history and shows its roles or lack of roles and tried to change how the world thinks, if not change the world. We have a considerable amount of trail at the end, which you don't see very often. We're pretty straightforward labeling books.

We've learned a lot since 1990 and some of what we told you in the book is not exactly right. Therefore, I think of this as not exactly a product recall but it is a model line enhancement. This is what might have been the 1991 model if we had done annual model changes but we didn't get around to it until 2007. It's some material that is useful that sums up what we've learned in the last many years.

Looking at the point where Toyota, as you said, is poised to become number one and saying, “Why Toyota Won,” I assume the expectation would be that looking another seventeen years out that Toyota would still be on top, that Toyota will continue winning, or do you think some of the rest of the Toyota executives talk about either from getting too large or potential backlash? Do you think about some of those fears or how is that going to play out?

We could say, “Toyota won and how could Toyota lose?” There are a number of features of the system that you look at that we don't know whether they could be sustained. We take a walk. We use the chapters in the book to do that. Factory practices are the easiest thing to transplant but even there, we see that Toyota is not building capacity abroad as fast as market demand would dictate because what we hear from back in Japan is that they literally don't have the planning organization. Who can put these mighty aircraft carriers close to the plants in place?

For example, my friends down in Brazil have been told by Toyota, “We would love to do another plant in Brazil but we just can't now or probably soon because we have no one who can design the thing and get it on the ground.” By the way, people forget or don't somehow or they're quite quick on the fact that Toyota put a new plant in place. It's better than anybody else's plant on the day it opens. A good and important thing is not the issue for a while but it's getting it right on day one. That still, for better or worse, is done by a small group of people mostly Japanese who know how to lay out of operation and get everything lined up.

A good and important thing is not the issue for a while, but getting it right on day one. Share on XThe production control logistics group is the key group. Most people don't even realize that that's the gang that does value stream thinking and the physical production side of the business. Therefore, Toyota's got to question how quickly can they even expand plants and they couldn't go too fast. Mr. Okuda came in as chairman back at the end of the 1990s. Okuda said, “We're going to go very fast,” and we're going for it. There was a lot of dispute within the company. Now Mr. Fujio Cho is the chairman who's a back-to-basics guy. It's not an accident that he's now the top guy because of this, “Let's make sure we can keep this thing going.”

Toyota could put some bad plants in place. GM, Ford, Chrysler, and the rest of the gang know what it is to try to dig your way out of a brownfield into what it should have been, to begin with. Therefore, we can't be assured that Toyota can continue to put good plants in place nor can we be assured that they could sustain plants. The management system again is pretty fair at this point.

The Toyota teaching system of how you create a manager in Japan historically started when you go to university. You work over at Toyota and you spend a year rotating around the business in 3 months making cars, 3 months selling cars, 3 months in engineering even if you knew nothing about engineering, 3 months in HR or some other function, purchasing. It was only at that point that they began their management education which by the way was to present you with an A3 on your desk when you sat down to go to the real work. It was a problem that you were supposed to solve.

By the way, there wasn't any hope that you were going to be able to solve this problem because it was about something by design you didn't know anything about. The whole idea and that's their A3 process is to teach you to describe the problem and then go see what the circumstances are, the process, the issues are, the recovery problem, envision a better circumstance, a better process, figure out who has to do what and when to get to that better process then please provide some evidence so we can judge whether the problem has already been solved. That's PDCA. Good old, Plan-Do-Check-Act guy.

That is the fundamental core of the management system and the teaching system. The boss, by the way, never tells you the answer. The boss keeps asking questions, “Why do you think this? What's the evidence? How can you show me this? Are you sure that's the right thing to do?” That teaching system required years and years to get to that wonderful thing, a fully seasoned Toyota manager. Yet, they're growing at such a rate that they're having to bring in enormous numbers of strangers to run these plants, who honestly don't have that much knowledge of the system.

It's something to think about that Jeff Liker and the folks in his group who put together The Toyota Way and The Toyota Way Fieldbook got full cooperation from Toyota. I wonder why they would have that. It's because Toyota needed new managers to read just books. If you're running the world's preeminent organization and you're depending on an outside guide to explain to your managers what management is, you just might be on thin ice.

It's not to say anything bad about just books, which are great, but to say that if that's the situation Toyota is in, watch out for low bridges. They could go negative. It's another way of saying it. A native behavior, that deep dark jungle none of us should want to go in is mass production. Therefore, that's how Toyota could lose, so that's point number one.

Point number two is the product of the system. We, at LEI, published a new book posthumously about Ward's, about their product and process development systems. It is what happened when Al, who truly was a brilliant man, went to Toyota to try to understand how they do product development. If you look at that material, this is a deep system. Jim Morgan, a wonderful guy at Ford, with Jeff Liker's help, has done the Toyota product development system book as well. Those two books, by the way, are complements. They're not doing the same thing. They're different pieces.

What's the name of the Al Ward book?

It's called Lean Product and Process Development. Therefore, you look at the product development system and you realize that they've got a tremendous problem-finding scale hustling up. A good part of their recalls issue, we can talk about that in a minute, is simply that they've got a lot of contract guest engineers who weren't trained in the Toyota system at all. They're using a lot of engineers and suppliers who are strangers because the suppliers are strangers.

Watanabe, the president's claim to the job was that he found the parts to keep Okuda's breakneck expansion program going. The question is, did he find the parts or didn't he? A good bit of the recall of business is not in the plant. In fact, most of it is not in the plant but in parts. It's from suppliers who don't understand the system or in Toyota's case, even using some contract engineers who don't understand the system.

Again, the risk is that you regress to that nasty mean called mass production because that's easy to understand, whereas, the Toyota system is hard to understand. That's the second way these folks could fail. The third way they could fail is again to extend that into the purchasing operation that I've watched with my very own eyes, not as a consultant of a sort but simply as an observer. What Toyota has tried to do in North America to create Toyota class suppliers with Delphi.

It is a staggering amount of continuous intensive interaction in which they ask questions about every process every day. That's great but who's going to ask those questions? The Toyota supplier support center was a spinoff of the old city operation command but that is a teeny group of people. Toyota doesn't depend on staff. They depend on managers who know how to improve processes. Therefore, if they have a little teeny staff that is supposed to run around and fix suppliers, just how good do you think those suppliers are going to be or more to the point, how much better than those suppliers working for Toyota's competitors are they going?

Toyota doesn't depend on staff. They depend on managers who know how to improve processes. Share on XIt's the same supplier. Delphi works for GM and Toyota. The whole idea here is not to get them to do a better job for GM. It's to get to do a better job for Toyota and that's very labor-intensive and that labor is in short to supply. I'll get to two more things. Toyota's dealing system in Japan is one of the wonders of the world. It is one that is co-owned by Toyota. They totally control the channel and therefore, they were able many years ago to apply lean thinking to car sales.

Not doing it at all the way people would expect here. This was the famous door-to-door sales operation in which they got to know every family who is a Toyota customer but probably they keep them. It's permitted Toyota to have a very stable 40% share in Japan for the last many years. That's not an accident because everybody understands they're not supposed to go beyond 40% or they will be visited by the fair trade. Therefore, you take profit rather than take more share.

Anyway, that selling system has never been able to export to the rest of the world, which is a great shame that Toyota dealers around the world may be average. In the States, they're much worse than average. What you have is a better-than-average product and a worse-than-average dealer and it still, as a package, a competitive deal. Over time, that's a real vulnerability. It's a missing piece of the puzzle.

I don't know what they're going to do. They periodically call me at Toyota. It was like, “Jim, can you help us fix our dealers?” Yet there never seems to be a plausible plan and I tried it once back in 1991 and 1992 and it was an enormous exercise in frustration. Some folks may have seen my little essay on farmers and hunters. Dealers are pure hunters. They just want the one point of transactions to get your money. Psychologically, they have a hard time apparently thinking about anything else.

For the Lean Solutions book that Dan Jones and I did, we had to go into a Lean car dealer in Portugal because, in Japan, we couldn't find one. Dan and his team invented one. We tell you about the book but that's one dealer in the world. It's probably got 60,000 dealers. It's a good question about whether Toyota will have any advantage in terms of how it touches the customer.

Over the long term, again, that becomes problematic if you don't treat group customers better. By the way, you save money by treating customers better. It turns out that good service is cheaper than bad service. It's cheaper for the customer in terms of saving their time. It is cheaper for the dealer in every aspect of the dealership. Yet Toyota just hasn't been able to get the dealer's attention.

Toyota Motor Sales out in California is where Jim Press hung out for many years. He's now the Toyota North America President. He had to get a lucky bunch of Americans who were hired before Toyota did Georgetown. This is back in the beginning of the '70s before they had thought about transferring any of their system to America. They put in place a very conventional dealing system.

The one part they have been able to fix is the park distribution business but just without looking at one of the distribution centers in the Boston area. That, they got right and it is terrific. It improves what they can do but that's the backside of the deal where you can do some things without the dealer even noticing. It's the front side of the deal that's the real issue.

Except for those four things together and you say, “Toyota could put some bad plants in place. They could sign up for some bad suppliers and they could do some bad engineering. They could continue to have that best mediocre and worse-than-average customer touch and those are all bad things when you look at the future in terms of where they might wind up.”

Finally, they have the overall general management system. It's, again, the folks who were taught the system. I've learned much of what I know about this from John Shook who sat at the right hand of Mr. Cho in setting up North America. That management system begins when you're a 22-year-old. It's this endless problem-solving business in which top-level managers never give answers. They just ask more questions but they're deeply informed questions. That's the key thing.

The job is to get the root cause to come up with a short-term temporary fix so that you can deal with the immediate problem but then put in place a long-term fix that eliminates the source of the problem. That management thinking is so different from what we do. All of the education we get is to make your numbers and move on to the next thing. That business was managed by results as opposed to the Toyota idea of managing by process. H. Thomas Johnson has been the guy who's probably explained that in the plainest language.

We haven't gotten very far as a society and that's in the US, in North America, or wherever. Toyota is constantly swimming against the current in trying to get its managers to behave in very different ways. I'm talking about its general managers. What we've seen so far is that there are a lot of guys who compete at the numbers as long as they have a higher level of truly Toyota train management that keeps it a little straight and narrow and they're okay. What we haven't seen is that from the bottom, from the age of 22, 23, or 25 creation of managers, who years later become very impressive people with the generation of Japanese managers.

For the long term, they've got to figure out how to do that. You have repeated swims against everything that we're still very much into career turning and that's gotten worse in the US and Europe. A few people now go into an organization and expect to stay there. There's a tremendous temptation to take a punch in Toyota, which is why you meet all these people who work there for 1 year, 2, or 3, and the funny thing, don't seem to know anything but by golly, they've got Toyota on the resume.

You pull it together and what we're trying to do is change the world by introducing a system that's new on five dimensions on how you design products, how you make them, how you deal with suppliers and customers, and how general management works. That's a big challenge. However, let's flip it over the other way. That's how Toyota can lose but let's remember that there is something very significant in the car industry, in particular, called momentum that the product is truly a durable good.

By the way, it's amazing how durable cars are these days. That anomaly of the guy who promotes Toyota has never owned one. I got somebody else's cars that I think are a little more interesting but even those guys, I am amazed. I keep cars for a long time and I got cars I had for a decade and they run great. That user experience goes on for a very long time, good or bad. When you put a bunch of bad cars out, as GM, Ford, and Chrysler did a long time ago, that memory lives on. Those things are rolling around for a long time to remind everybody. It's rolling billboards.

Toyota has put a lot of good cars out and the business that the media has been thrashing about with the recalls, most of those vehicles were recalled before anybody ever even knew about them. They're picked up at the next service interval. These problems that Toyota has discovered are going to be problems in the future but for the most part, have not been significant problems in user experience so far.

As long as they're able to do that, and by the way, I can trust that with the famous GM X car break situation of years ago which was one of the key moments of GM sliding down the chute. They clearly had a problem and the company stonewalled. Toyota has been doing almost the opposite of stonewalling, admitting problems that may not even be problems.

Toyota has been doing almost the opposite of stonewalling, admitting problems that may not even be problems. Share on XThe point is, for the moment, they still got the customer convinced they got a pretty good product. Hence, the high selling prices and the big broken chair. It takes a long time to bleed that off, even if Toyota has started to do some bad things. There's a momentum to this business that extends for 1 decade or 2, even if you start to screw up.

The GM and Ford people, the executives love to complain that they've gotten a lot better and woe is them. The reputation hasn't caught up to them.

That's right. That's the opposite. Once you do screw up, you get enough 15-yard penalties in this game that puts you all the way back on your own goal line. Toyota hasn't, to this point in my view, significantly screwed up, they get what the winner gets. They get a grace period. Now, by the way, from the standpoint of someone like Fujio Cho, that's a bad thing because what they believe is instantaneous feedback. They try to build a management system that generates instantaneous feedback.

The last thing they want is a lag between starting to do something wrong and the customer starting to punish them for it. That's a real risk for them. For the short term, can Toyota screw up? For the short term, the answer is no. For the long term, absolutely. They think about it every day at headquarters, about how can we avoid screwing up at a point in time when almost any company would be dumb, fat, and happy. Now that's totally different from politics. What they are certainly obsessed with in the short term is what could happen to them politically. On that one, none of us knows but there's lots of downside potential.

It seems like some of the excuse-making has popped up, whether it's from politicians talking about currency valuations in the Yen and all sorts of external things that are “unfair” to the big three. It reminds me a lot of the perception that The Machine That Changed the World helped break down when it was published. It's not all of these other factors.

It's a little discouraging to hear some of this stuff but here's the reality. There are a lot of people feeling a lot of pain. There are a lot of politicians out there whose job it is to own. Let's talk about the positive side. In politics, you're supposed to deal with people's pain. It's disappointing but it's not surprising, particularly given the incredibly poor game that the American companies have played that all of Motown looks like a Detroit alliance.

If the people haven't learned, the teacher hasn't taught. Share on XIt used to be they couldn't win away games. These guys haven't won a home game in the jury. You're going to get politics if the home team can't play the game. The natural thing is to start saying that the referee is on the take and you see it all over the world. Name a situation in a sport where your national team loses and loses where you don't blame some nefarious factor.

The other guys using steroids or the referee's on the take or whatever. That's going to happen. It's disappointing. I certainly think of myself predominantly and primarily as an educator. If the people haven't learned, the teacher hasn't taught, which is another favorite Toyota saying, “Where did I go wrong? I did my best but it doesn't seem like I've done enough.”

Important Links

- Lean Enterprise Institute

- Jim Womack

- The Machine That Changed the World

- The Toyota Way

- The Toyota Way Fieldbook

- Lean Product and Process Development

- Lean Solutions

- LeanPodcast@Gmail.com

- Book by Al Ward

- The Toyota Product Development System: Integrating People, Process And Technology

- Jim's essay on farmers and hunters

- GM and the X-cars (info here and here)

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More