Mark's Note: This is the week my wife and I are physically moving from San Antonio to the DFW area, so thanks to those who have helped with guest posts.

Today's guest post is by Sue Kozlowski, who is part of the team at Techsolve, a team that's based in Cincinnati. In the past, I've collaborated with them on some training and they're a great group. She has co-authored or contributed to a number of books, which you can see on Amazon.com. You can find them on Twitter as @TechSolveInc. Today's post brings some practical tips and methods you can use…

By: Sue Kozlowski, Senior Director, Lean Healthcare Solutions, Techsolve Inc.

Wouldn't it be nice to have a magic wand that dissolved all resistance from a change team? Think of it – everyone open to every idea, leaders willing to let the value to the customer rule decision-making, money made available to invest in improvement ideas, frontline staff actively promoting change to their colleagues. What a lovely daydream!

Wouldn't it be nice to have a magic wand that dissolved all resistance from a change team? Think of it – everyone open to every idea, leaders willing to let the value to the customer rule decision-making, money made available to invest in improvement ideas, frontline staff actively promoting change to their colleagues. What a lovely daydream!

In reality, as we all know, there are many forces at play within any change team. What are some of the problems we face in the process improvement world?

- Politics: Whose project gets approved and what does that do to one's political standing? Who gets to say, “My area is the most important because we were selected for improvement?”

- Discomfort with a new way of doing things: Like crossing your arms differently (right over left, or left over right), new ways can just feel wrong

- Fear of losing expertise: If I'm a master of the process now, will I be able to be a master of the process when it's different?

- Love of chaos: My reason for being is to fix problems in a chaotic process – if the process is smooth, and there aren't any problems, there might not be a need for me!

- Lack of confidence in the organization: I don't trust that we will get the support from leadership to keep doing it the new way

- Negative peer pressure: If I support this change, my co-workers will think I'm a brown noser or a patsy

- Inertia: Nothing ever changed after the last five “fads of the month,” so what makes this any different? I'll just wait this one out, too.

In spite of all this “resistance,” we use the Lean approach to develop tremendously successful improvements and tangible results when we trust the process and include front-line employees and leaders in the change process.

I use the term “resistance” in quotation marks because most of these feelings are our natural response, as human beings, to a change in the status quo – whether that's a new driving pattern due to construction, or a different way of scheduling surgery patients.

What are some of the things that can be done do to make progress if these types of natural responses are present in team members?

For senior leaders:

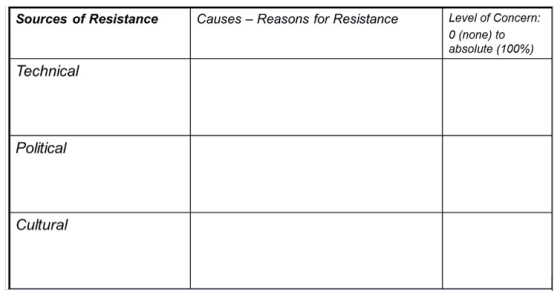

Team members look to leaders to gauge the level of commitment to change. They know, more by body language than by words, whether leaders are “supportive” (in a passive way, waiting to see what will happen) or “engaged” (in an active way, participating in the change initiative). Leaders may need guidance, at first, to understand this. Successful Executive Champions and Process Owners will show, by their actions, that they are ready to help the team develop and sustain improved processes. In a meeting of leaders, we can use the change tool “Political-Technical-Cultural” assessment (see below) to bring out those factors that are being left unsaid – the elephants in the room – and clear the air so that the improvement project will get the support it deserves.

- For a Technical – Political – Cultural Assessment:

- Make a flip chart with three rows, labeled “Technical,” “Political,” Cultural.”

- Ask each team member to write on sticky notes their ideas of things that exists today that would be a barrier to improvement in each of these categories (one idea per sticky note).

- Once all the sticky notes are up, discuss each one and whether it is a barrier that needs to be addressed in order to set the team up for success.

- Create an action plan to ensure appropriate follow-up.

For team members:

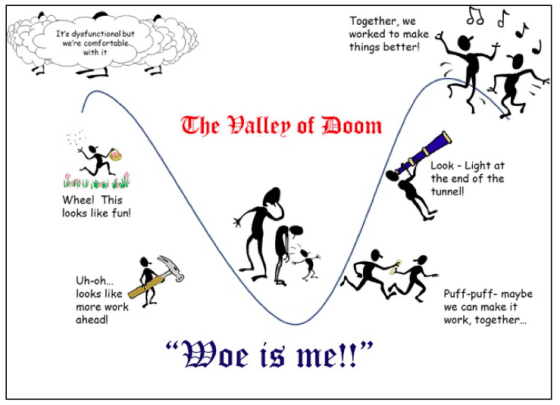

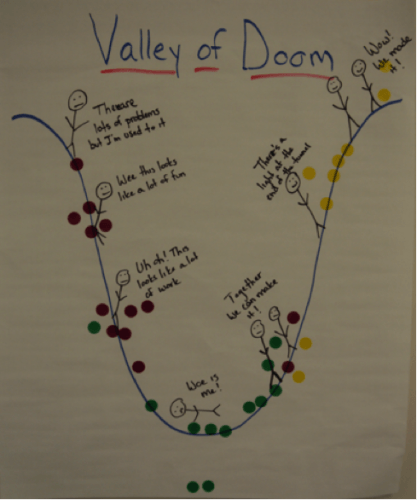

Doing activities like the crossing-your-arms exercise can help teams to understand that change may feel uncomfortable, but isn't necessarily harmful. Using a tool like “The Valley of Doom” can help team members feel comfortable in their discomfort – a natural part of the change journey, instead of a reason to retreat.

- The Valley of Doom:

- Draw the valley on a flip chart, labeling the seven phases.

- Ask each team member to place a sticky dot (or “x”) in the place where they feel they are now. Use a different color each time you ask this (on each day of an event, for example).

- Discuss where the team is – many will be in different places in the valley, and some will move forward and backwards as the project progresses.

- Generally, team members will start on the left side and move to the right side by the end of the project or event.

For process owners:

Giving up control is hard, especially when a leader is used to calling the shots. Help departmental leaders to understand how the team must own the solution, in order to ensure sustainability. For those leaders who are masters of chaos, and can't understand their role without chaos, help them to identify things they don't currently have time for – and would like to do on a regular basis, including learning new aspects of the business or participating on organization-wide teams to share their expertise.

For staff in departments undergoing change:

We say that we should communicate “eight times, eight ways,” but some of us don't quite get there. Use a Communication Plan to identify what needs to be shared, at what points in the process, so that the department staff members are not surprised to find out that change is coming.

- Communication Plan

- Make a simple chart with columns for “What needs to be communicated,” “Who is the audience,” “How will it be shared,” “When will it be shared,” “Activity Leader,” and “Status.”

- After each meeting, ask the team what needs to be communicated at that time, and complete the chart as needed. Use the “Status” column to indicate that tasks are completed, or perhaps in need of assistance to complete.

For staff who have seen it all before:

Tell them that you expect them to be skeptical at the start – it's natural reaction. Ask for an open mind, and a good-faith effort in the change process, at least through once cycle of change. Once an individual experiences a Lean activity, and sees the difference between front-line engagement and other types of top-driven change, he or she usually becomes a supporter of this “new” type of change process.

For everyone:

Using tools like “Make Sure This Fails!” can also bring out some of the humor in process change – mixing it up can generate a lot of laughter, with a follow-up lesson that if the process improvement is to succeed, the team must ensure sure that the “recipe for failure” is addressed by including Lean countermeasures in the Future State work process.

As experienced Lean process improvement leaders know, a person who starts out with a negative about change can turn into a very ardent supporter once the Lean process is experienced.

- Make Sure This Fails!

- On a flip chart, write the title of the project (or, of a specific process step) in the middle, within a circle.

- Ask each team member to use sticky-notes to come up with ways to ensure that the project or process step will fail (one idea per sticky-note).

- After the team members are done with their ideas, group similar ideas together and then discuss each point.

- If the team determines that there is a risk of failure due to an idea, create an action plan to ensure that the team will address that issue during creating of the Future State and implementation plan.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

[…] https://www.leanblog.org/2016/03/resistance-is-futile-practical-change-techniques-for-all-levels-of-y… […]