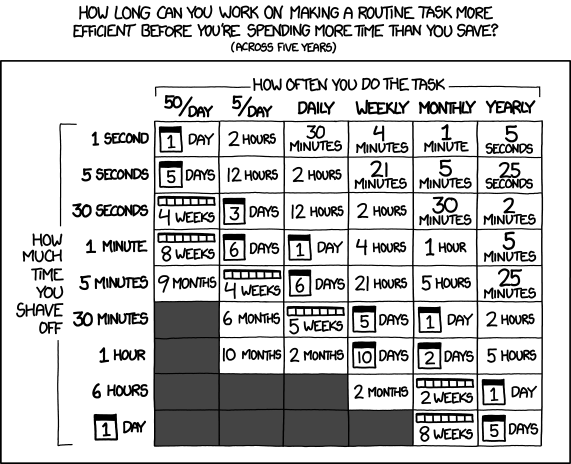

Hat tip to Tony Manos of 5S Supply for sharing (via twitter) this interesting table that shows how a few minutes (or even a few seconds) can really add up across a period of five years.

My friend Paul Akers has a great little book called 2 Second Lean: How to Grow People and Build a Fun Lean Culture. Paul shares the classic Kaizen advice that even a time savings of two seconds is worth celebrating because the benefits add up over time.

This chart, created by the site xkcd, shows how that time adds up, with the left axis being the amount of time saved and the top axis being the frequency of your task:

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

A challenge for some Lean folks I have seen from industry is that any time saving is worth pursuing and priority is not all that important. This belief is based on the concept that we are going to fix everything anyway so priority really isn’t relevant.

The complexity and current state of healthcare is that so many things need improving that prioritization is essential. I would change the chart for healthcare to be a one-year break even point instead of 5 years.

I see your point, anonymous… I think the beauty of “small Kaizen” (daily Kaizen, etc.) as we talk about in our “Healthcare Kaizen” book is that lots of people can work on little 2-second improvements simultaneously. I think there’s a need to prioritize larger improvements, but if we’re all doing Kaizen within our work, I think prioritization is less important.

And, as I should have mentioned in the post, some have pointed out on Twitter that improving the value added work itself (the topic of this chart) is not the only way to improve. There’s a huge opportunity in the Lean approach to reduce delays and the non-value added steps… but that doesn’t mean we should ignore opportunities to improve the way the actual work is done.

You’re right on Mark.

Top down and bottom up. We need systems in healthcare that deliver both. Much of the bottom up is lots of seconds of waste elimination opportunity and not that difficult to do and sustain if we have the right culture and systems in place.

Someone asked me if the math adds up… it basically does.

It’s measured across five years.

1 second per day * 50 times/day = 50 seconds/day * 365 days * 5 years = 91250 seconds = 25.3 hours or approximately 1 day

That assumes you’re doing something 24x7x365 instead of just an 8-hour work day… but still a fun chart.

Good stuff! The question that I have “Is the time that you save going to process more of what you looking for?” I was working with a client that was on a same track of reducing cycle time. He was focused on reducing cycle time for several stations which is great. My question was if you save 10%, 15%, 50% of cycle time, are you going to see 1, 10, 10 more units at the end of the line? If so, what is the math?

My point is focus on improvements which is going to have the biggest bang for your buck.