In the Lean methodology, one of the most well-known–and most misunderstood–practices is the “Gemba walk.”

The word Gemba means “the actual place.” It's where the actual work happens. In healthcare, that might be a hospital unit or a laboratory. In manufacturing, the assembly line. In tech, the developer's room. Wherever your value is created, that's your Gemba.

The purpose of going to the Gemba is to learn. To understand. To support. But far too often, Gemba walks become something else entirely: a tightly scheduled tour of metrics, boards, and scripted conversations.

When that happens, we risk missing the very thing we came to see.

Boards Aren't the Work

In many organizations, Gemba walks have become synonymous with reviewing visual boards:

- KPI charts,

- huddle metrics,

- kaizen improvement tracking, or

- A3 updates.

And to be clear, these boards can be helpful–when they're alive, evolving, and connected to real improvement conversations.

But when a leader's visit becomes only about what's on the board, we've lost the thread.

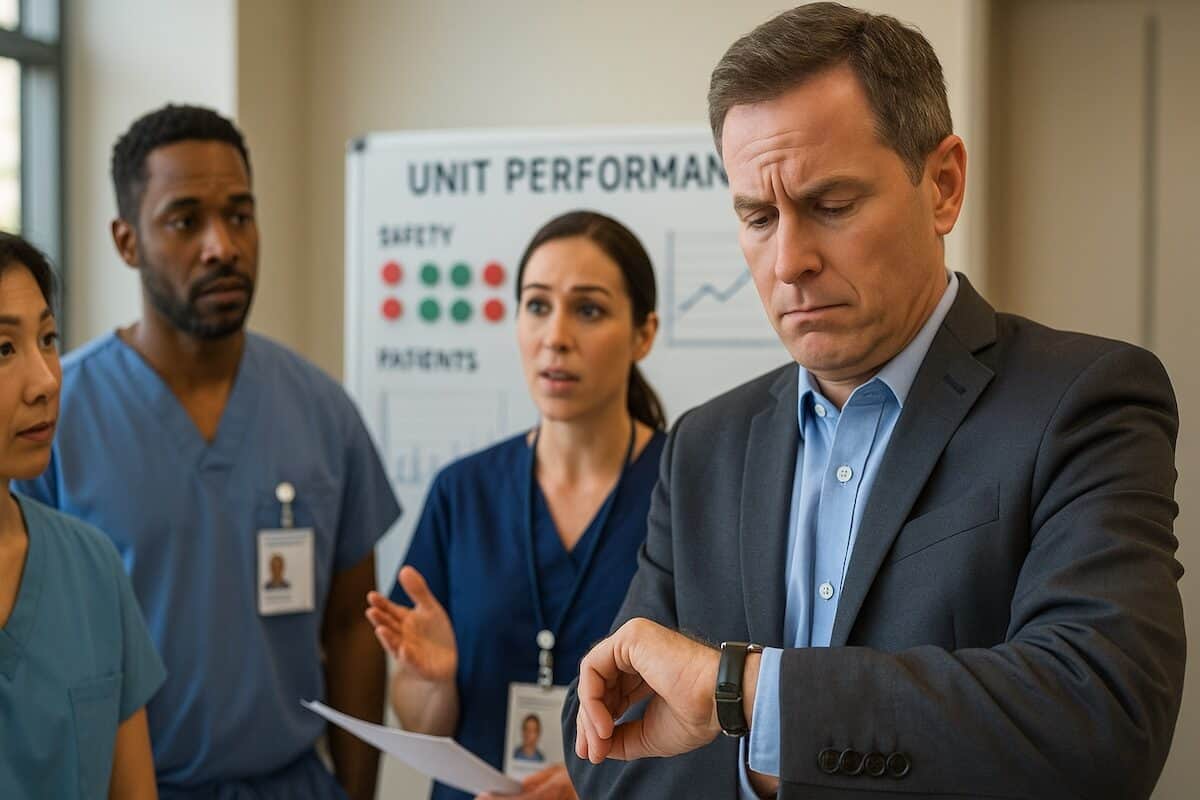

I once shadowed a leader on a Gemba walk who spent a full minute reviewing whether today's numbers were green or red. He listened to status updates. He nodded, asked if the board was up to date (it was), thanked the team, and moved on. The walk was “on schedule.”

But nothing was learned. No problems were surfaced. No conversations sparked. The board was treated like a scoreboard, not a springboard.

Gemba Isn't a Performance

Here's the irony: the more we treat the Gemba as a quick audit or status update, the more our teams feel pressure to make things look good rather than be real.

If leaders are in a rush, people learn to rehearse their lines. They present polished boards. They give safe answers. They protect their time–and their credibility–by keeping things surface-level.

That's not a high degree of Psychological Safety. That's compliance.

Leaders sometimes say they want a culture of continuous improvement, but the behavior we model in our Gemba visits tells a different story. If we're performing a Lean ritual instead of having a Lean mindset, our people notice.

The Schedule Problem: No Slack, No Space, No Substance

Another issue is time. I've seen Gemba walk agendas where leaders are scheduled to visit five or six departments in an hour. Each stop is slotted for 10 minutes. The route is mapped, the teams are prepared, the clock is ticking.

What if something important comes up?

What if a nurse says, “Actually, we've been really struggling with the new handoff process…” and it's minute nine?

What if someone hints at a patient safety issue, but the next huddle is starting in two minutes?

We often preach the value of slack in systems–that overburdened people can't do quality work.

But do we allow slack in our leadership systems? Or are we so focused on efficiency that we forget effectiveness?

Real conversations require space. The messy stuff–the valuable stuff–doesn't follow a script. If we're too tightly scheduled to stay and dig deeper, we're not leading. We're scanning.

You might not want to get caught looking at your watch:

What Effective Gemba Looks Like

So what does a meaningful Gemba walk look like?

It starts with mindsets:

- Curiosity over confirmation

- Listening over judging

- Presence over performance

It continues with time:

- Leave slack in your schedule. Don't put yourself in a position to constantly feel rushed.

- Build in “stay time.” If a conversation is rich, stay with it. Let people know they're worth your time.

And it thrives with better questions:

- “What's one small frustration you've been dealing with this week?”

- “What's something we keep putting a Band-Aid on instead of fixing?”

- “Where are we getting in our own way?”

- “How safe do you feel bringing up problems here?”

When those questions are asked with humility and intent–and when there's enough space for people to answer–trust begins to grow. And with trust, comes honesty. And with honesty, comes improvement.

Going to the Gemba Isn't the Goal. Understanding Is.

A Gemba walk isn't about being seen. It's about seeing clearly. And that only happens when we slow down enough to look past the charts, beyond the metrics, and into the lived experiences of our teams.

Let's not reduce Gemba to a Lean checkbox on a leadership calendar.

Let's protect the purpose behind it: understanding the work, supporting the people doing it, and learning how to make it better together.

That takes time. That takes humility. And that takes intention.

But those are the same ingredients we need for real, lasting change.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Thank you so much for this article. It is very timely reinforcement of some of the positive intention, time, and humility our leaders are displaying. It’s not easy to keep doing though, which is why I really appreciate hearing the importance of these concepts from a trusted voice in the field. Thanks especially for using healthcare examples in the article! It makes it more relevant and meaningful for our leaders.

Thanks for reading and for sharing your thoughts, Caitlin!