I'm guessing that many of you know Bruce Hamilton's wonderful “Toast Kaizen” video from GBMP.

When I use clips of the video for teaching Lean and Kaizen principles, part of the discussion is about how to go from the current state to the future state. How can we improve the process to make the right toast the right way in the right quantities?

One common Kaizen ground rule is that we look to change the process before we jump to the conclusion that we need new equipment. Let's use “creativity over capital,” as they say.

The humble toaster in the video is actually a very average toaster. The toasting cycle is about two minutes, depending on how dark you want your toast.

The humble toaster in the video is actually a very average toaster. The toasting cycle is about two minutes, depending on how dark you want your toast.

Most toasters take about that long to toast.

By rearranging the kitchen and changing the toast-making process in different ways, you're able to easy get the toasting time down from over four minutes to just over two minutes. Bruce demonstrates how to cut the toast “turnaround time” in half, just by making simple changes… without a newer, faster, better toaster.

But what if you DID want (or need?) toast more quickly.

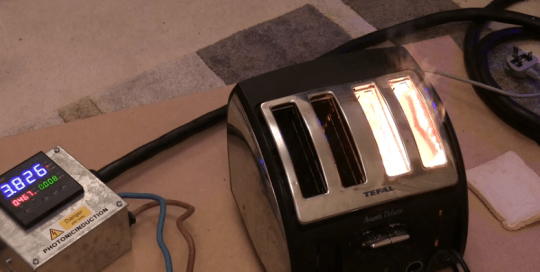

These mad scientists have figured out a way… but I'm not sure it's really safe for the average kitchen:

Glorious lunatics overdrive toaster to make toasts in under 10 seconds

Yikes! You can see a cool animated GIF here of the flame-throwing toaster here.

Or, see the video where they crank up the wattage on the toaster:

I'm not sure that's necessary, but it would certainly get the toast turnaround time to about 30 seconds.

I admire the creativity (a good Kaizen trait) but we have to think safety first.

A comparison:

| Toast Round | Toaster | Turnaround Time | Safety/Quality Notes |

| 1 | Normal – Far from Bread | 4:12 | Wrong type of bread, didn't wash hands, bread on (possibly) dirty counter |

| 2 | Normal – Closer to Bread | 2:17 | Paper towels hanging too close to toaster |

| 3 | High Wattage | 0:20 | Holy *$@#!!! |

Kids, don't try this at home.

Adults, don't try this in Lean training!

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

top gear + myth busters + monty python, the best of all worlds! best quote from the video “the toast is done”

Mark,

A while back I was asked to participate in a class at a prestigious engineering school in Boston (located on the Charles River). We viewed a snippet from the current condition of Toast Kaizen and the class was then prompted for improvements. In mock ignorance, students turned a blind eye to the process waste and instead tried to outdo each other with wild and impractical “engineering solutions” to reduce the cycle time for the toasting operation. Very funny.

Bruce

That’s hilarious, Bruce! Thanks for sharing that. As a graduate of the school I think you’re referring to, I’m glad it as “mock ignorance.” :-)